Production Description

GB/T10045 E501T-1

ISO 17632-A-T422PC2H10

NB/T 47018 E501T-1

AWS A5.36 E71T1-C1A2-CS1

Flux-cored wire is also called powder-cored wire and tubular wire. It is divided into two categories: gas-entrained and non-gas-protected. The surface of the flux-cored wire is the same as that of the solid wire, and is made of materials such as low-carbon steel or low-alloy steel with good plasticity. The manufacturing method is to first roll the steel strip into a U-shaped section shape, then fill the solder powder prepared according to the dosage into the U-shaped steel strip, roll it tightly with a rolling mill, and finally make it into different specifications by drawing. cored wire.

Flux cored wire is divided into seamed and seamless flux cored wire according to production characteristics. The finished wire of seamless flux-cored wire can be copper-plated, and the moisture-proof performance during storage and the conductivity during welding are better than those of seamed flux-cored wire.

Flux cored wire has different classification methods according to different situations.

According to the protection situation, it can be divided into four types: gas protection (CO2, Ar-rich mixed gas) and self-protection, submerged arc and open arc.

According to the wire diameter, it can be divided into thin diameter (below 2.0mm) and thick diameter (above 2.0mm).

According to the wire section, it can be divided into simple section and complex section.

According to the power supply used, it can be divided into AC steep drop characteristic power supply and DC flat characteristic power supply.

According to the filling material, it can be divided into slag-forming flux cored wire (titanium oxide type, titanium calcium type, calcium fluoride type) and metal powder cored flux cored wire.

Common gas shielded flux cored wires are: AWS A5.29/5.28 E71T1-C(M), E81T1-K2, E81T1-NI1, E91T1-K2, E101-K3, E111T1-K3, E80C-G, E90C-G, E110C-G, etc. (general diameter 1.2mm-1.6mm)

Common self-shielding flux cored wire: general diameter: 1.6mm-3.2mm

Common submerged arc surfacing flux-cored wires are: AWS A5.23 F71A, F8A4, F9A4, F11-A8, etc. (general diameter: 2.4mm-4.0mm)

DEPOSIT COMPOSITION:( shielded gas-CO2) (%)

|

Principal component |

C |

Mn |

Si |

S |

P |

|

Typical Results |

0.06 |

1.38 |

0.45 |

0.010 |

0.019 |

MECHANICAL PROPERTIES:

|

test item |

Yield StrengthRel/Rp0.2 MPa |

Tensile Strength Rm/MPa |

Elongation A/% |

Charpy V-Notch J (ft•lbf) |

|

|

-20℃ |

-30℃ |

||||

|

Typical Results |

475 |

551 |

29 |

155 |

90 |

Content of diffusion hydrogen in deposited metal(Typical Results):5.4ml/100g (Mercury method)

Welding reference specification:

|

wire diameter(mm) |

0.8 |

0.9 |

1.0 |

1.2 |

1.4 |

1.6 |

|

welding voltage(V) |

20-24 |

20-24 |

20-25 |

22-26 |

22-28 |

24-30 |

|

welding current(A) |

70-150 |

80-160 |

100-170 |

180-280 |

200-280 |

240-300 |

|

extension length(mm) |

15-20 |

15-20 |

15-20 |

15-20 |

15-20 |

15-20 |

|

Gas flow(l/min) |

20-25 |

20-25 |

20-25 |

20-25 |

20-25 |

20-25 |

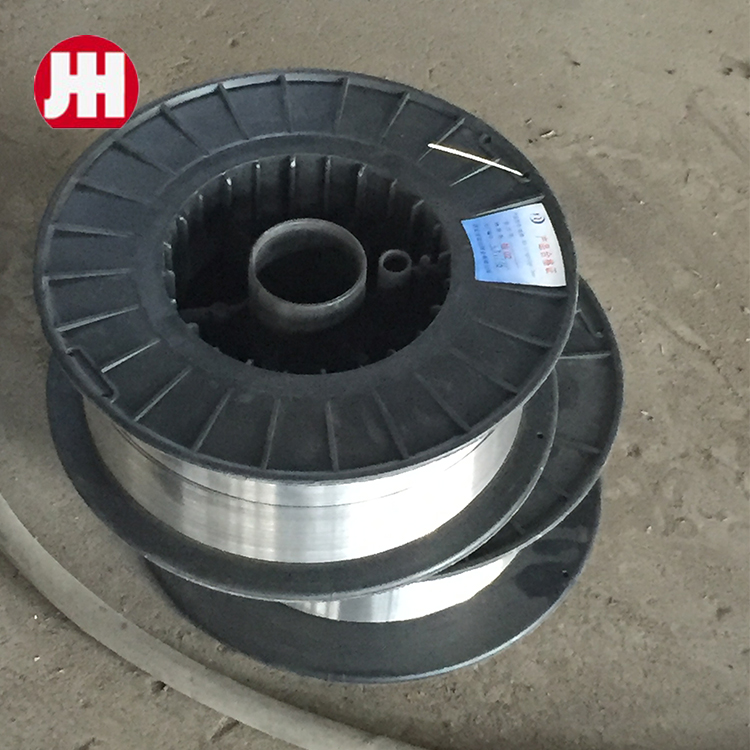

Specification & Package

0.8mm, 5kgs/box, 15kg per box. 20kg per box,

0.9mm, 5kgs/box, 15kg per box. 20kg per box,

1.0mm, 5kgs/box, 15kg per box. 20kg per box,

1.2mm, 5kgs/box, 15kg per box. 20kg per box,

1.6mm, 5kgs/box, 15kg per box. 20kg per box,

Color print box is available.

OEM/ODM Package Available:

we also can do different kgs package, different brand print.

we can print the package as your requests, we have professional designer to make the package design with your brand & LOGO.

Product Video

Visit & Exhibition

Welcome to visit us for a friendly and long term cooperation, please tell us your time schedule, we will arrange for you. we will also join the relate exhibitions, we can meet each other on the exhibition. Friendship first, and business is professional, you can trust us forever.

Do you have the following trouble when order the products?

1.Is the Supplier Reliable?

We produce this products more than 30 years, we have advertise on Alibaba, Made-in-China, after you place the order, whenever you want to see the production, we can send you video or picture to check. Our export team also have more than 15 years experience, we can solve all the problem you may meet in business. Welcome to visit us.

2.Is the Quality Stable?

We do test randomly in production, and test shipment before ex works. We have professional QC workers and high level test equipment, to assure each shipment in good quality.

3.Is the Payment Safe?

We choose one of the largest bank in China, to assure your payment will arrive in safe condition, and all of the benefit company must send them the shipping document copy to bank for record.

4.Shipment Delivery?

Normally we can arrange shipment in 15 days, if customize the package, shipment can be arranged in one month, please negotiate with our customer service, we will tell you a firm date after check our production and your order quantity.

Please don't hesitate to contact us

Sales Manager: Cherry Zhang

Tel: 0086-311-68035766

Fax: 0086-311-68035566

Mobile: 008613739727566

WhatsApp / Wechat: 008613739727566

Email: info@steeltoolschina.com

Send inquiry