SG2 Welding Wire: Low Spatter, High Strength, MIG/MAG

Sg2 Welding Wire is a key solution in the manufacturing industry, specifically within Fabricated metal products and Manufacturing of welding materials and equipment. This article explores how HEBEI YUJINHONG TECHNOLOGY CO.,LTD. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Sg2 Welding Wire Overview

- Benefits & Use Cases of Sg2 Welding Wire in Manufacturing of welding materials and equipment

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Sg2 Welding Wire from HEBEI YUJINHONG TECHNOLOGY CO.,LTD.

Sg2 Welding Wire Overview

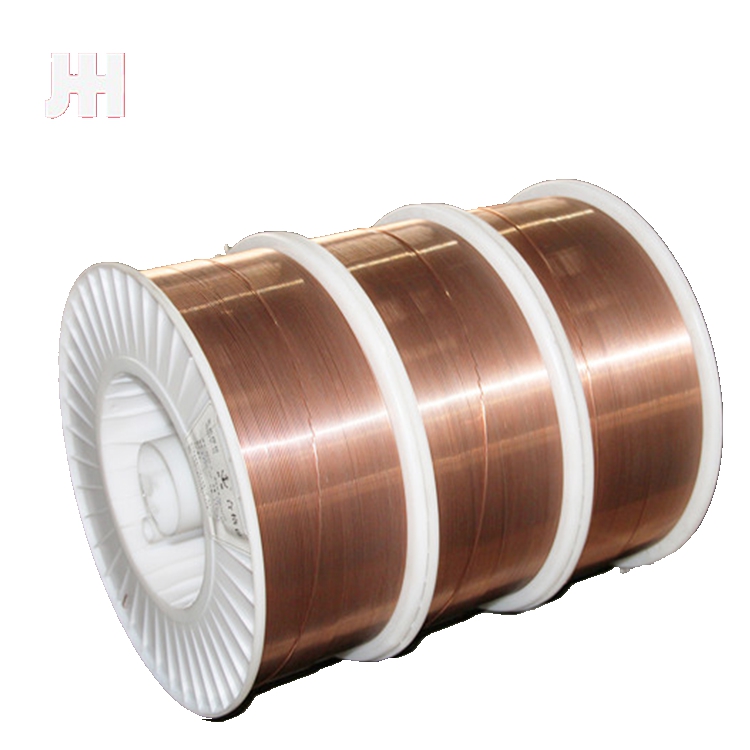

Sg2 Welding Wire—often classified to AWS A5.18 ER70S-6 and EN ISO G3Si1—is the industry’s go-to solid wire for high-quality GMAW/MIG and MAG welding of mild and low-alloy steels. Its balanced alloying and copper-coated surface promote a smooth, stable arc with low spatter, reliable wetting, and excellent bead appearance. For B2B buyers in fabricated metal products and equipment manufacturing, SG2 helps standardize welding performance across automated cells and manual stations, minimizing variability and rework. Typical diameters range from 0.8 to 1.6 mm, supporting carbon steel fabrication under CO2 or M21 (Ar/CO2) shielding gases.

HEBEI YUJINHONG TECHNOLOGY CO.,LTD. engineers its SG2 wire for consistent feedability and low fume generation, backed by process-controlled drawing, copper-coating, and spool winding to reduce wire cast/helix issues. Where heavier mill scale is present, buyers frequently compare SG2 with SG3 welding wire (G4Si1), which offers higher deoxidizers; many plants deploy both grades depending on base-material condition. Whether you’re welding structural frames, pressure-bearing components, or general fabrication, our SG2 supports repeatable productivity while aligning with global standards.

Benefits & Use Cases of Sg2 Welding Wire in Manufacturing of welding materials and equipment

Across manufacturing of welding materials and equipment, Sg2 Welding Wire excels in chassis, brackets, machine frames, pipe spools, agricultural equipment, and general steel fabrication. Its chemistry supports sound fusion even on slightly contaminated surfaces, while its arc stability enhances robotic welding for repeatable, high-speed deposition. Fabricators gain cleaner beads and less post-weld grinding, which improves takt time and reduces consumable usage. When fabricating thicker sections or dealing with heavier scale, many operations switch to SG3 welding wire to leverage its higher Si/Mn deoxidation, while keeping SG2 as the shop standard for cleaner steels.

Key advantages include dependable wire feeding, tight diameter tolerances, and copper-coating that protects against corrosion and improves electrical contact. Combined with CO2 or mixed gas, SG2 delivers low spatter and minimal porosity risk. HEBEI YUJINHONG TECHNOLOGY CO.,LTD. supports integration into automated lines with consistent spool winding and layer precision for uninterrupted robotic operation. While soldering copper wire requires a different filler system and lower heat process, our portfolio and engineering team help you select the right consumable for each joint design, metal type, and productivity goal.

Cost, Maintenance & User Experience

Total cost of ownership for Sg2 Welding Wire extends beyond price-per-kilogram. Buyers realize ROI through faster travel speeds, reduced spatter cleanup, fewer stoppages due to tangles or poor winding, and higher first-pass yield. Consistent copper-coating preserves contact tip life and ensures stable current transfer, lowering maintenance on torches and liners. For multi-shift operations, reliable feeding and low fume output support safer, cleaner work cells and fewer productivity disruptions.

Feedback from fabricated metal product manufacturers highlights smooth arc starts, predictable bead profile, and strong mechanical properties in both short-circuit and spray transfer modes. Quality teams note a reduction in rework when process windows are maintained, particularly with M21 shielding gas. HEBEI YUJINHONG TECHNOLOGY CO.,LTD. offers technical guidance on wire diameter, stick-out, and parameters, helping customers benchmark deposition rate versus heat input to meet throughput and distortion targets. Packaging options (such as 5–18 kg spools and drums, depending on availability) streamline changeovers and support lights-out robotic cells, compounding the cost benefits over time.

Sustainability & Market Trends in manufacturing

Manufacturers face mounting pressures to decarbonize, minimize waste, and comply with health and safety regulations. Sg2 Welding Wire contributes by enabling efficient heat input control, reducing rework and consumable waste, and supporting optimized fume profiles when paired with suitable shielding gases and parameters. As automation and cobot welding expand, wire consistency and low-spatter performance are increasingly important to reduce energy use per welded joint and keep production cells cleaner for longer intervals.

HEBEI YUJINHONG TECHNOLOGY CO.,LTD. invests in process control, surface treatment, and packaging that protect wire integrity and reduce material loss during handling. We track evolving standards and customer environmental goals to recommend process settings and compatible gases that balance productivity with ESG commitments. In parallel, we help plants evaluate when SG2 suffices versus when SG3 welding wire is more sustainable due to fewer defects on rusty or scaled steels—cutting rework and extending component life. The result is a practical pathway to higher output with lower environmental impact.

Conclusion on Sg2 Welding Wire from HEBEI YUJINHONG TECHNOLOGY CO.,LTD.

Sg2 Welding Wire is a proven, high-performing choice for fabricated metal products and the broader manufacturing of welding materials and equipment. Its stable arc, clean bead, and consistent feedability help operations boost throughput while controlling costs and quality risk. HEBEI YUJINHONG TECHNOLOGY CO.,LTD. stands behind every spool with process expertise, reliable supply, and application support—from standard SG2 to SG3 options and guidance on specialized processes like soldering copper wire. Contact us: email: info@steeltoolschina.com — Visit our website: https://www.steeltoolschina.com

-

What is a medium-frequency pulse? What types of welding are suitable for?NotíciasNov.24,2025

-

Why is the overall cost of CO2 welding lower than that of shielded metal arc welding?NotíciasNov.21,2025

-

Welding Knowledge 6NotíciasNov.20,2025

-

What is a low-frequency pulse? What types of welding are they suitable for?NotíciasNov.19,2025

-

Why are the weld joints from CO₂ gas shielded welding of such high quality?NotíciasNov.18,2025

-

J506 Welding Rod - Low Hydrogen, All-Position, AC/DC E7016NotíciasNov.17,2025