ian. . 20, 2025 05:16

Back to list

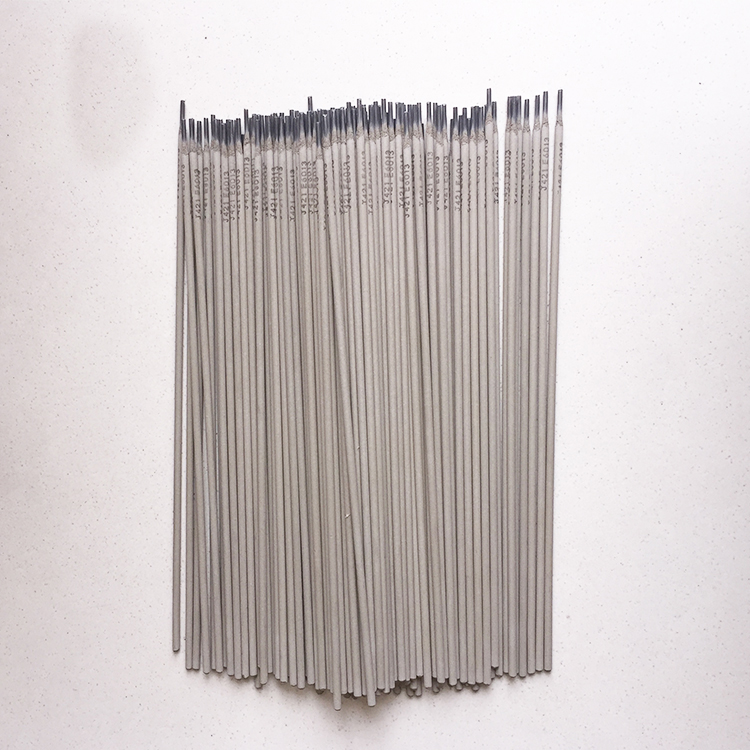

welding rod rutile

The world of welding materials can often seem both intricate and daunting, particularly when navigating the multitude of options available to suit specific tasks and conditions. Among the diverse welding rod options, the rutile welding rod stands out due to its unique properties and applications. With over 20 years of hands-on experience in the welding industry, I have observed firsthand the exceptional attributes that make rutile welding rods a preferred choice for many welding professionals. This insight is grounded in extensive practice, industry collaboration, and ongoing research, providing a reliable perspective on why these rods continue to be an authoritative staple in the field.

In terms of industry standards and trustworthiness, rutile welding rods are compliant with significant international regulations, ensuring quality across various applications. These rods have been tried and tested extensively, gaining certifications from reputable welding institutes and standard organizations worldwide. Their global recognition attests to their high-standard manufacturing processes and consistent performance. As an advocate for welding safety and excellence, adherence to these standards gives me confidence in recommending rutile welding rods to peers and clients, ensuring both safety and product integrity. Moreover, the economic benefits of using rutile welding rods cannot be understated. They provide a cost-effective solution for a range of welding tasks without substitutions of quality. The reduced need for specialized skill sets and minimal post-weld finishing makes these rods particularly appealing to businesses aiming to optimize their operational budgets without compromising on quality or safety. In many projects where budget constraints are paramount, relying on rutile rods has been a strategic choice, allowing for high-quality welds at a fraction of the downtime and expense. Having established their efficacy and quality, routine skepticism about long-term availability and supplier reliability is addressed by sourcing from certified distributors and manufacturers known for consistent production practices. This ensures authenticity while maintaining a robust supply chain that meets project demands promptly. For any professional in the welding industry, establishing connections with reliable suppliers forms the backbone of sustained project efficiency and client satisfaction. In conclusion, rutile welding rods epitomize a blend of practical application, reliability, and cost-efficiency. Their user-friendly nature, coupled with versatility across various welding positions and adherence to stringent safety standards, positions them as a preferred choice in the welding community. My long-standing experience with these rods reaffirms their position in the market as highly reliable and effective, making them an indispensable tool in the arsenal of any professional welder.

In terms of industry standards and trustworthiness, rutile welding rods are compliant with significant international regulations, ensuring quality across various applications. These rods have been tried and tested extensively, gaining certifications from reputable welding institutes and standard organizations worldwide. Their global recognition attests to their high-standard manufacturing processes and consistent performance. As an advocate for welding safety and excellence, adherence to these standards gives me confidence in recommending rutile welding rods to peers and clients, ensuring both safety and product integrity. Moreover, the economic benefits of using rutile welding rods cannot be understated. They provide a cost-effective solution for a range of welding tasks without substitutions of quality. The reduced need for specialized skill sets and minimal post-weld finishing makes these rods particularly appealing to businesses aiming to optimize their operational budgets without compromising on quality or safety. In many projects where budget constraints are paramount, relying on rutile rods has been a strategic choice, allowing for high-quality welds at a fraction of the downtime and expense. Having established their efficacy and quality, routine skepticism about long-term availability and supplier reliability is addressed by sourcing from certified distributors and manufacturers known for consistent production practices. This ensures authenticity while maintaining a robust supply chain that meets project demands promptly. For any professional in the welding industry, establishing connections with reliable suppliers forms the backbone of sustained project efficiency and client satisfaction. In conclusion, rutile welding rods epitomize a blend of practical application, reliability, and cost-efficiency. Their user-friendly nature, coupled with versatility across various welding positions and adherence to stringent safety standards, positions them as a preferred choice in the welding community. My long-standing experience with these rods reaffirms their position in the market as highly reliable and effective, making them an indispensable tool in the arsenal of any professional welder.

Previous:

Latest news

-

AWS E6013 Welding Electrodes: All-Position & Smooth Arc RodsNewsAug.25,2025

-

E312 Electrode: High Strength Welding Rod for Dissimilar MetalsNewsAug.24,2025

-

J506 Welding Rod: High-Strength, Crack-Resistant ElectrodeNewsAug.23,2025

-

E71T-1 Shielding Gas for Superior Welding Quality & EfficiencyNewsAug.22,2025

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025