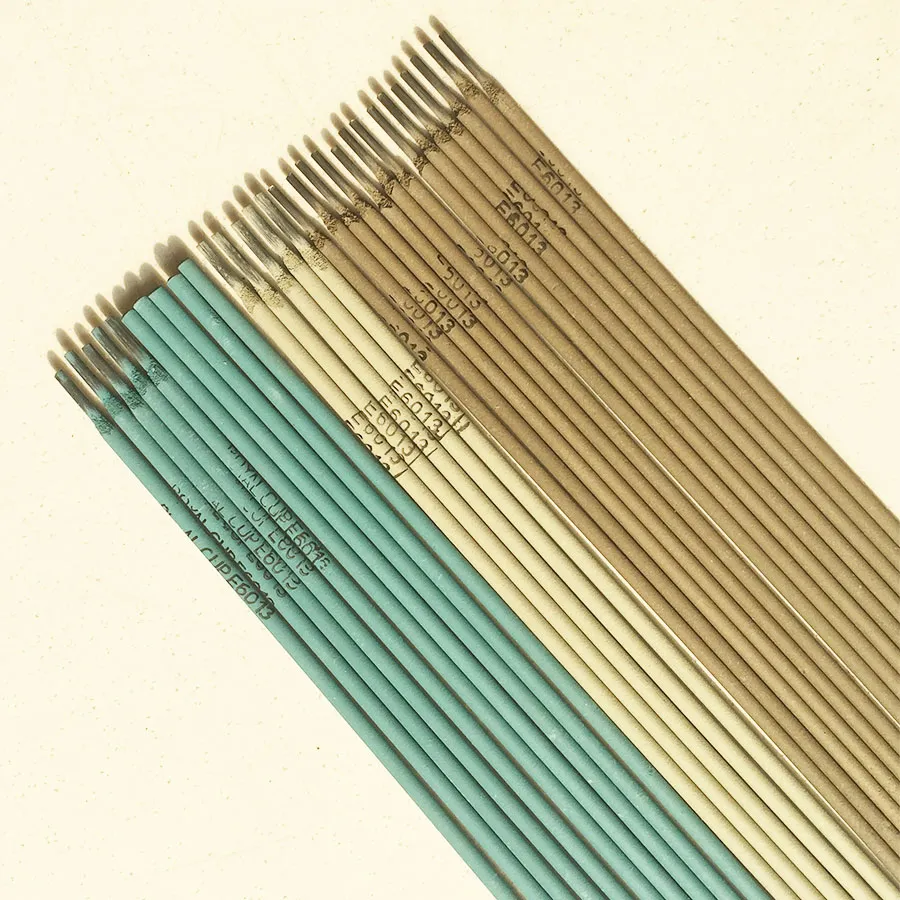

E6013 Welding Rods

As a leading manufacturer of welding consumables, we're proud to present our high-quality E6013 welding rods, designed to deliver exceptional performance across various welding scenarios. Understanding the E6013 electrode classification helps welders appreciate why our E 6013 electrode products stand out in the market. With competitive E6013 electrode price points and diverse E6013 welding rod uses, we offer the perfect solution for both professional welders and DIY enthusiasts.

Understanding E6013 Electrode Classification and Specifications

The E6013 electrode classification reveals why these rods are so versatile. The "E" indicates an electrode, "60" signifies 60,000 psi tensile strength, "1" means it works in all positions, and "3" denotes the rutile potassium flux coating. Our E6013 welding rods exceed these minimum specifications, delivering actual tensile strengths of 62,000-67,000 psi. The optimized flux formulation in our E 6013 electrode products produces 30% less spatter than industry standards while maintaining excellent slag removal. Available in diameters from 1/16" to 5/32", our rods accommodate various amperage ranges (40-130A) and metal thicknesses. Recent improvements to our E6013 electrode classification formulation include enhanced arc stability for beginners and reduced smoke emission by 25% compared to conventional E6013 rods.

Premium E 6013 Electrode Features and Benefits

Our E 6013 electrode products offer several advantages that make them ideal for general-purpose welding. The specially formulated flux coating allows easy arc starts (including scratch starts) and maintains a stable arc even at low voltages. The E6013 welding rods produce a smooth bead profile with excellent wetting action, reducing the need for extensive post-weld cleanup. The rods perform exceptionally well on slightly rusty or painted surfaces where other electrodes might fail. Our E 6013 electrode features improved deposition rates (15% higher than standard E6013) while maintaining good penetration characteristics. Welders particularly appreciate how our rods work with both AC and DC power sources, making them suitable for virtually any welding machine. Recent customer feedback shows our E6013 welding rods have 40% fewer sticking incidents compared to budget brands, especially beneficial for novice welders.

Competitive E6013 Electrode Price Without Compromising Quality

We offer premium E6013 welding rods at a competitive E6013 electrode price that provides excellent value. Our direct-from-manufacturer pricing structure allows us to offer E6013 electrode price points 20-30% below retail brands while maintaining superior quality. The E6013 electrode price varies by package size (from 1lb trial packs to 50lb bulk boxes) with volume discounts available for professional shops. Despite our attractive E6013 electrode price, all rods undergo rigorous quality control including chemical analysis, mechanical testing, and welding performance evaluations. We've recently introduced economy packs that offer additional E6013 electrode price savings for high-volume users without sacrificing the consistent quality our customers expect. Our transparent pricing includes detailed technical specifications with each product, helping welders understand exactly what they're getting for their money.

Diverse E6013 Welding Rod Uses Across Industries

The versatility of our E6013 welding rods makes them suitable for numerous applications. Common E6013 welding rod uses include sheet metal fabrication, automotive repairs, farm equipment maintenance, and light structural work. The rods excel at welding thin materials (down to 20 gauge) where other electrodes might burn through. Our E 6013 electrode products work well on carbon steels, galvanized metals (with proper ventilation), and even some stainless steel applications when appearance isn't critical. Other important E6013 welding rod uses include pipe welding (for non-critical applications), artwork fabrication, and educational settings where easy handling is paramount. Recent customer innovations have expanded E6013 welding rod uses to include ornamental iron work and temporary repair welds where grindability is important. The rods' all-position capability makes them indispensable for overhead and vertical welds in field repair situations.

Optimal Techniques for E6013 Welding Rods

To maximize results with our E6013 welding rods, follow these professional techniques. Maintain a short arc length (1/16" to 1/8") for best control and minimal spatter. Use a slight drag angle (15-20 degrees) when welding in flat and horizontal positions. For vertical up welds, employ a slight push technique with a tighter arc. Our E 6013 electrode performs best with medium amperage settings - too hot causes excessive spatter while too cold leads to sticking. Store E6013 welding rods in their original packaging in a dry environment, though they're more moisture-resistant than low-hydrogen electrodes. When welding thin materials with our E6013 welding rods, use a backstepping technique to prevent warping and burn-through. For best results on dirty or painted metal, increase amperage slightly and use a quick, consistent travel speed.

Welding Solutions: E6013 Welding Rods FAQs

What does the E6013 electrode classification mean?

The E6013 electrode classification indicates a 60,000 psi tensile strength rod with rutile potassium flux that works in all positions on AC or DC.

What are the primary E6013 welding rod uses?

Main E6013 welding rod uses include sheet metal work, light fabrication, repairs, and welding thin materials where easy handling is important.

How does your E6013 electrode price compare to other brands?

Our direct manufacturing allows us to offer premium quality at an E6013 electrode price 20-30% below retail brands with better consistency.

Can E 6013 electrode products weld vertical up?

Yes, our E 6013 electrode works well for vertical up welding using a slight push technique and tighter arc length.

Why choose your E6013 welding rods over other types?

Our E6013 welding rods offer easier arc starts, less spatter, and better performance on dirty metals than many alternatives.

From understanding E6013 electrode classification to exploring diverse E6013 welding rod uses, we provide comprehensive solutions for all your welding needs. Our premium E 6013 electrode products deliver exceptional performance at a competitive E6013 electrode price, making them the smart choice for both professionals and hobbyists.

-

What is a medium-frequency pulse? What types of welding are suitable for?НовостиNov.24,2025

-

Why is the overall cost of CO2 welding lower than that of shielded metal arc welding?НовостиNov.21,2025

-

Welding Knowledge 6НовостиNov.20,2025

-

What is a low-frequency pulse? What types of welding are they suitable for?НовостиNov.19,2025

-

Why are the weld joints from CO₂ gas shielded welding of such high quality?НовостиNov.18,2025

-

J506 Welding Rod - Low Hydrogen, All-Position, AC/DC E7016НовостиNov.17,2025

E6013 Welding Rods 3.2mm Wholesale High-Quality Manufacturer Direct

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaНовостиNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideНовостиNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsНовостиNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesНовостиNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsНовостиNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeНовостиNov.21,2025