ม.ค. . 10, 2025 12:24

Back to list

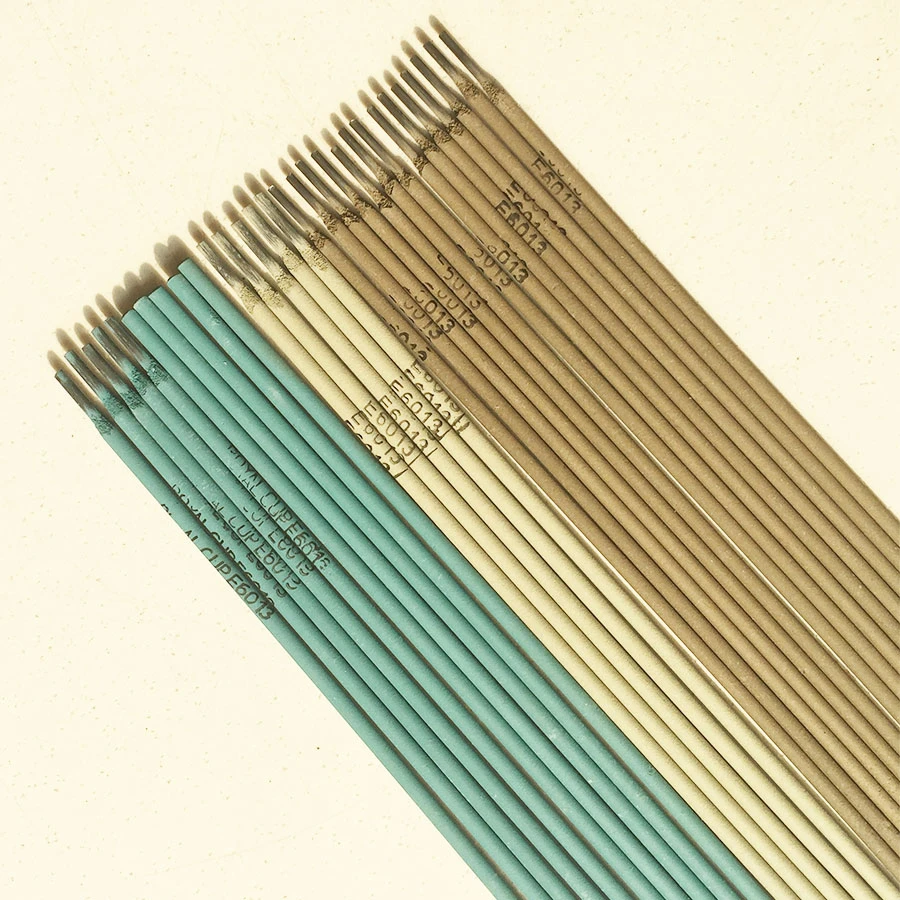

carbon steel welding rod

The 3/32 welding rod, a critical tool for many welding projects, offers both versatility and precision that few other sizes can match. Known for its optimal balance in electrode thickness, it is a favorite among both novice and experienced welders. Much more than just a piece of metal, the 3/32 welding rod serves as a fundamental component in creating strong, durable welds across a range of applications.

Trustworthiness in the use of a 3/32 welding rod also extends to its compositional quality. These rods are often coated with high-quality flux to facilitate smooth and stable arcs, leading to a cleaner weld with fewer defects. This not only influences the strength and appearance of the weld but also the overall safety and integrity of the structures being welded. Understanding the properties of the rod's material can provide confidence in its application, knowing it will consistently yield expected results. In terms of product-specific advantages, the 3/32 welding rod is available in various material compositions including mild steel, stainless steel, and particularly aluminum. Each type caters to different environmental demands and project specifications, ensuring compatibility with the workpiece. This diversity in selection allows welders to choose the optimal rod for their particular task, enhancing performance and outcome. The rod's usability is further enhanced by its compatibility with various welding machines, making it an accessible tool regardless of equipment type. Whether using a MIG, TIG, or Stick welder, the 3/32 rod integrates seamlessly, adding to its reputation as a highly versatile electrode choice. In summary, the 3/32 welding rod is more than just an accessory in a welder’s toolkit; it is a finely-tuned instrument that combines expertise, experience, and trusted manufacturing practices to deliver outstanding results. Its balanced properties make it suitable for a wide range of welding tasks, cementing its place as a staple in the welding industry. For anyone looking to achieve precision and reliability in their welds, the 3/32 rod stands out as a preferred choice.

Trustworthiness in the use of a 3/32 welding rod also extends to its compositional quality. These rods are often coated with high-quality flux to facilitate smooth and stable arcs, leading to a cleaner weld with fewer defects. This not only influences the strength and appearance of the weld but also the overall safety and integrity of the structures being welded. Understanding the properties of the rod's material can provide confidence in its application, knowing it will consistently yield expected results. In terms of product-specific advantages, the 3/32 welding rod is available in various material compositions including mild steel, stainless steel, and particularly aluminum. Each type caters to different environmental demands and project specifications, ensuring compatibility with the workpiece. This diversity in selection allows welders to choose the optimal rod for their particular task, enhancing performance and outcome. The rod's usability is further enhanced by its compatibility with various welding machines, making it an accessible tool regardless of equipment type. Whether using a MIG, TIG, or Stick welder, the 3/32 rod integrates seamlessly, adding to its reputation as a highly versatile electrode choice. In summary, the 3/32 welding rod is more than just an accessory in a welder’s toolkit; it is a finely-tuned instrument that combines expertise, experience, and trusted manufacturing practices to deliver outstanding results. Its balanced properties make it suitable for a wide range of welding tasks, cementing its place as a staple in the welding industry. For anyone looking to achieve precision and reliability in their welds, the 3/32 rod stands out as a preferred choice.

Previous:

Latest news

-

High Quality E71T-11 Welding Wire from China – Flux Cored, Easy to UseNewsJul.28,2025

-

High-Quality SG2 Welding Wire for Superior PerformanceNewsJul.27,2025

-

E6011 Welding Rod for Arc Welding – High Performance & VersatilityNewsJul.26,2025

-

Welding Rod 2.0 mm for Structural Welding - High Strength & PrecisionNewsJul.25,2025

-

Factory Supply Cast Iron Welding Rods AWS ENi-CI High StrengthNewsJul.24,2025

-

Premium 7018 Welding Rods Electrodes for Strong WeldsNewsJul.23,2025