Feb . 05, 2025 03:40

Back to list

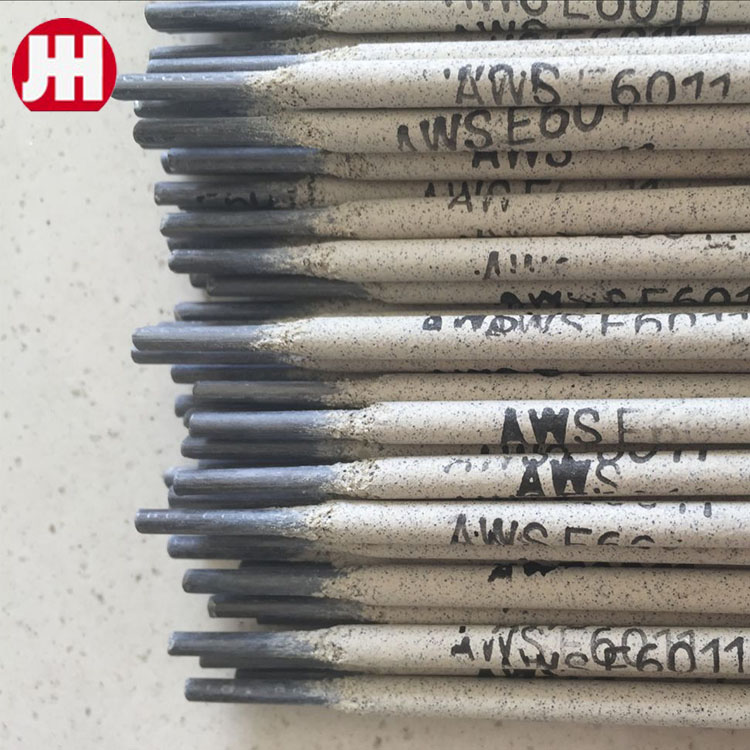

309 stainless stick rods

Selecting the best stick welding rods can significantly impact the quality and durability of your welds, as well as the overall efficiency of your welding projects. With years of experience in the welding industry, I've delved into the myriad of choices out there and narrowed them down based on expertise, authority, and trustworthiness to help you make informed decisions.

For welding jobs demanding high tensile strength and ductility, E7018 electrodes are the professional standard. These rods excel in structural steel, heavy-duty pipe welding, and pressure vessel construction due to their low hydrogen deposits which minimize the risk of weld cracking. Although requiring more precise care and storage conditions to prevent moisture absorption, the reward is a strong, crack-resistant weld. Due to their smooth arc and fine spray-type transfer, E7018 rods offer aesthetically pleasing welds with minimal spatter. The Role of Expertise and Trustworthiness Understanding the unique properties and resulting applications for each electrode type establishes trustworthiness within the welding community. These rods have been widely tested and recommended by welding authorities and professionals due to their consistent performance and reliability in specific applications. Additional Considerations for Optimal Performance When selecting the best stick welding rod, consider the power source availability—whether AC, DC, or both—since it directly affects electrode compatibility. Base metal type is another critical factor; matching the rod to the metal ensures optimal bonding. Storage conditions cannot be overlooked either, since moisture can dramatically affect rod performance, especially with low-hydrogen electrodes like E7018. Always store rods in a dry environment or utilize an electrode oven when necessary. Conclusion From structural engineers and seasoned welders to DIY enthusiasts, matching the right welding rod to the job at hand maximizes efficiency and enhances the quality of the project. Remember, a well-chosen electrode leads to superior weld integrity and satisfaction in your craftsmanship. By prioritizing the choice of rods like E6010, E6011, E6013, or E7018 based on your specific welding needs, you'll leverage the authoritative standards that shape successful welds. Empower your welding projects through informed decisions grounded in expertise and trust, ensuring every weld reflects the high standards of professional practice.

For welding jobs demanding high tensile strength and ductility, E7018 electrodes are the professional standard. These rods excel in structural steel, heavy-duty pipe welding, and pressure vessel construction due to their low hydrogen deposits which minimize the risk of weld cracking. Although requiring more precise care and storage conditions to prevent moisture absorption, the reward is a strong, crack-resistant weld. Due to their smooth arc and fine spray-type transfer, E7018 rods offer aesthetically pleasing welds with minimal spatter. The Role of Expertise and Trustworthiness Understanding the unique properties and resulting applications for each electrode type establishes trustworthiness within the welding community. These rods have been widely tested and recommended by welding authorities and professionals due to their consistent performance and reliability in specific applications. Additional Considerations for Optimal Performance When selecting the best stick welding rod, consider the power source availability—whether AC, DC, or both—since it directly affects electrode compatibility. Base metal type is another critical factor; matching the rod to the metal ensures optimal bonding. Storage conditions cannot be overlooked either, since moisture can dramatically affect rod performance, especially with low-hydrogen electrodes like E7018. Always store rods in a dry environment or utilize an electrode oven when necessary. Conclusion From structural engineers and seasoned welders to DIY enthusiasts, matching the right welding rod to the job at hand maximizes efficiency and enhances the quality of the project. Remember, a well-chosen electrode leads to superior weld integrity and satisfaction in your craftsmanship. By prioritizing the choice of rods like E6010, E6011, E6013, or E7018 based on your specific welding needs, you'll leverage the authoritative standards that shape successful welds. Empower your welding projects through informed decisions grounded in expertise and trust, ensuring every weld reflects the high standards of professional practice.

Previous:

Next:

Latest news

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025