E71T GS Welding Wire — No Gas Needed, Low Spatter

e71t gs welding wire is a key solution in the manufacturing industry, specifically within Fabricated metal products and welding materials. This article explores how HEBEI YUJINHONG TECHNOLOGY CO.,LTD. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- e71t gs welding wire Overview

- Benefits & Use Cases of e71t gs welding wire in welding materials

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on e71t gs welding wire from HEBEI YUJINHONG TECHNOLOGY CO.,LTD.

e71t gs welding wire Overview

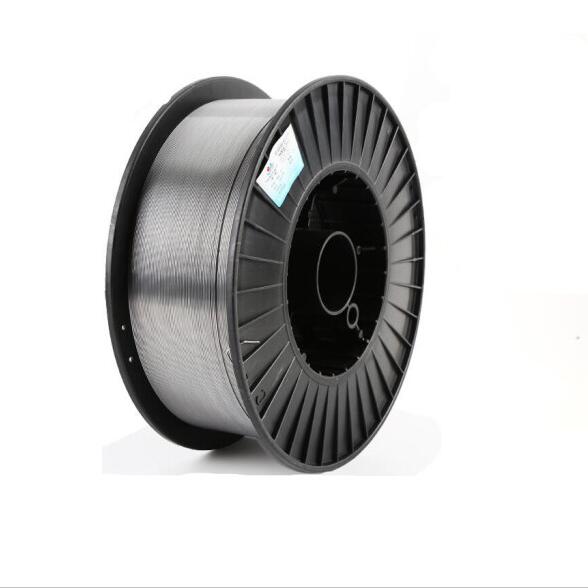

E71T-GS welding wire is a self-shielded flux-cored wire engineered for single-pass welding on thin to medium-gauge carbon steel, including lightly galvanized substrates. Classified under AWS A5.20 as E71T-GS, it runs on DCEN (straight polarity) and eliminates the need for external shielding gas, making it ideal for shop floors and outdoor jobs where wind control or gas logistics are challenging. As an all-position, single-pass wire, it’s widely used for lap and fillet welds on sheet metal, maintenance and repair tasks, and general fabrication. Typical diameters include 0.8/0.9/1.0/1.2 mm, with tensile strength commonly reaching 480–500+ MPa (≥70 ksi). HEBEI YUJINHONG TECHNOLOGY CO.,LTD. manufactures this e71t gs welding wire with tight flux fill control and consistent wire geometry to ensure stable arc starts, low spatter, and predictable bead profile. Available in common spool sizes and OEM/private-label options, the company supports B2B buyers with ISO-aligned quality systems, batch traceability, and responsive lead times—crucial for Fabricated metal products manufacturers aiming for throughput, repeatability, and cost control. Whether you call it e71t gs flux core or e71t gs mig wire for self-shielded applications, the product delivers a practical balance of productivity and bead aesthetics for everyday production and MRO welding.

- Relevance: Self-shielded, single-pass solution for mild and galvanized steel in fabrication and repair.

- Specs: AWS A5.20 E71T-GS; DCEN; all-position; typical diameters 0.8–1.2 mm; single-pass fillet/lap welds.

- Manufacturer: HEBEI YUJINHONG TECHNOLOGY CO.,LTD. with ISO-based QC, consistent arc performance, and reliable supply.

Benefits & Use Cases of e71t gs welding wire in welding materials

In welding materials portfolios, e71t gs welding wire stands out for portability, simplicity, and productivity. It’s commonly applied in HVAC ducting, automotive body repair, light frames, appliance enclosures, agricultural equipment, site repair, and field fabrication. Because it’s self-shielded, teams can weld outdoors or in drafty shops without setting up gas cylinders, hoses, and regulators. The wire’s arc characteristics promote quick learning curves for operators and reduce rework on thin-gauge steels. With an easily removable slag and clean bead profile, E71T-GS flux core reduces post-weld finishing time compared with lower-grade alternatives. HEBEI YUJINHONG TECHNOLOGY CO.,LTD. optimizes flux chemistry for stable arc transfer, wet-out on lap joints, and minimized porosity on appropriately prepared surfaces. Competitive advantages include less downtime (no gas changeovers), faster setup, and consistent feedability thanks to precise wire diameter control. For B2B buyers, these attributes translate into reliable takt times across multiple cells, especially where mixed-material thicknesses are common. Whether specified as e71t gs flux core or e71t gs mig wire for self-shielded processes, the product is a pragmatic choice for single-pass welding that balances bead appearance, penetration, and operator comfort—all backed by HEBEI YUJINHONG’s technical support and application guidance.

- Applications: Sheet metal fabrication, maintenance and repair, outdoor jobs, light frames, and galvanized components.

- Advantages: No shielding gas required, all-position capability, low spatter, easy slag removal, consistent bead quality.

- Expertise: HEBEI YUJINHONG TECHNOLOGY CO.,LTD. offers process tuning, parameter recommendations, and dependable supply.

Cost, Maintenance & User Experience

Total cost of ownership for e71t gs welding wire favors operations that value speed and simplicity. By removing shielding gas purchases, rentals, and logistics, you reduce indirect costs and floor complexity. Productivity gains come from quicker setups, fewer consumable changeovers, and the ability to weld in environments where gas coverage would be unreliable. For maintenance, store spools dry, use knurled drive rolls sized to the wire, pair with correct contact tips, and keep liners clean to ensure smooth feeding. HEBEI YUJINHONG TECHNOLOGY CO.,LTD. supplies clear parameter windows, so teams can dial in voltage, wire feed speed, and stickout for best arc stability and minimal spatter. Fabricated metal products customers frequently report improved first-pass acceptance rates on thin-gauge weldments and time savings in post-weld cleanup. Over multiple shifts, those incremental gains add up to measurable ROI—especially in MRO cells and job shops with high part variety. User experience highlights include easy arc starts, predictable puddle control in all positions, and slag that lifts without fighting the bead. Combined with consistent spool-to-spool quality, buyers can standardize on a single e71t gs welding wire across many light fabrication tasks, simplifying purchasing and inventory.

- TCO levers: No shielding gas, faster setups, less rework, streamlined inventory.

- Maintenance tips: Dry storage, proper drive rolls, correct tips/liners, clean work surfaces for best results.

Sustainability & Market Trends in manufacturing

Manufacturers are prioritizing lower carbon operations, smarter logistics, and waste reduction. Self-shielded wires like e71t gs welding wire align with these goals by minimizing gas cylinder production and transport, reducing ancillary hardware, and enabling efficient, right-first-time welding on thin materials—cutting scrap and rework. In parallel, regulatory focus on worker health underscores the need for proper fume extraction and PPE; HEBEI YUJINHONG TECHNOLOGY CO.,LTD. supports customers with product datasheets and best-practice guidance to help EHS teams set safe parameters. Market-wise, the Fabricated metal products segment continues to diversify into short-run, mixed-material workcells where quick changeovers and flexible welding consumables shine. HEBEI YUJINHONG invests in process consistency, recyclable packaging options, and ISO-driven quality to meet global buyer requirements, including RoHS- and REACH-conscious supply chains where applicable. As reshoring and nearshoring increase demand volatility, the company’s agile production and export experience provide dependable lead times. The result is a future-ready supply partner delivering e71t gs flux core solutions that meet productivity needs today while supporting sustainability and compliance targets across your plants.

- Trends: Lower CO2 logistics, right-sized production, EHS compliance, and flexible fabrication.

- Positioning: HEBEI YUJINHONG TECHNOLOGY CO.,LTD. combines quality, eco-conscious packaging, and responsive supply.

Conclusion on e71t gs welding wire from HEBEI YUJINHONG TECHNOLOGY CO.,LTD.

For B2B decision-makers in manufacturing and fabricated metals, e71t gs welding wire offers a practical blend of speed, simplicity, and consistent results—especially for single-pass, thin-gauge applications. Backed by HEBEI YUJINHONG TECHNOLOGY CO.,LTD.’s quality control, application support, and reliable supply, it’s a dependable consumable to standardize across repair cells and light fabrication lines. If you’re evaluating e71t gs mig wire or self-shielded flux core options for productivity gains and lower operating complexity, this product deserves a place on your shortlist. Contact us: email: info@steeltoolschina.com — Visit our website: https://www.steeltoolschina.com

- Value: Reliable single-pass performance, minimal setup, and strong ROI in welding materials workflows.

- Reputation: HEBEI YUJINHONG TECHNOLOGY CO.,LTD. is a trusted, responsive manufacturer and exporter.

- Strong CTA: Contact us: email: info@steeltoolschina.com — Visit our website: https://www.steeltoolschina.com

-

What is a medium-frequency pulse? What types of welding are suitable for?BalitaNov.24,2025

-

Why is the overall cost of CO2 welding lower than that of shielded metal arc welding?BalitaNov.21,2025

-

Welding Knowledge 6BalitaNov.20,2025

-

What is a low-frequency pulse? What types of welding are they suitable for?BalitaNov.19,2025

-

Why are the weld joints from CO₂ gas shielded welding of such high quality?BalitaNov.18,2025

-

J506 Welding Rod - Low Hydrogen, All-Position, AC/DC E7016BalitaNov.17,2025