The Importance of Quality Materials

When it comes to welding, the type of welding wire you use can greatly affect the outcome of your work. Among the many options available, certain brands and types of welding wire stand out for their consistency, strength, and versatility. The ER70S-6 TIG rod, MIG solid wire, Vulcan ER70S-6 MIG solid welding wire, and Matheson ER70S-6 are some of the top choices for both professional welders and DIY enthusiasts. In this article, we’ll dive into what makes these products ideal for a variety of welding applications and how to choose the right one for your needs. Whether you're a novice welder or an experienced professional, understanding the features of these welding wires is essential for producing high-quality results.

Why Choose the ER70S-6 TIG Rod for Your Next Project?

The ER70S-6 TIG rod is one of the most popular choices among TIG welders due to its excellent performance and versatility. This welding rod is made of a high-quality steel alloy, which contains manganese and silicon, making it perfect for welding on materials such as carbon steel, mild steel, and even low-alloy steel. The ER70S-6 TIG rod is ideal for applications where cleanliness and precision are paramount. It produces minimal spatter and offers a smooth, consistent bead, ensuring a high-quality finish.

The ER70S-6 TIG rod is especially suitable for welding in industries like automotive, aerospace, construction, and pipe fabrication. Whether you're working on thin or thick materials, this welding rod delivers excellent penetration and strong welds, ensuring long-lasting durability. Its unique composition allows it to work well in various positions, making it ideal for both horizontal and vertical welds. If you want to achieve clean, high-quality welds with minimal effort, the ER70S-6 TIG rod is your go-to option.

The Benefits of MIG Solid Wire in Welding Applications

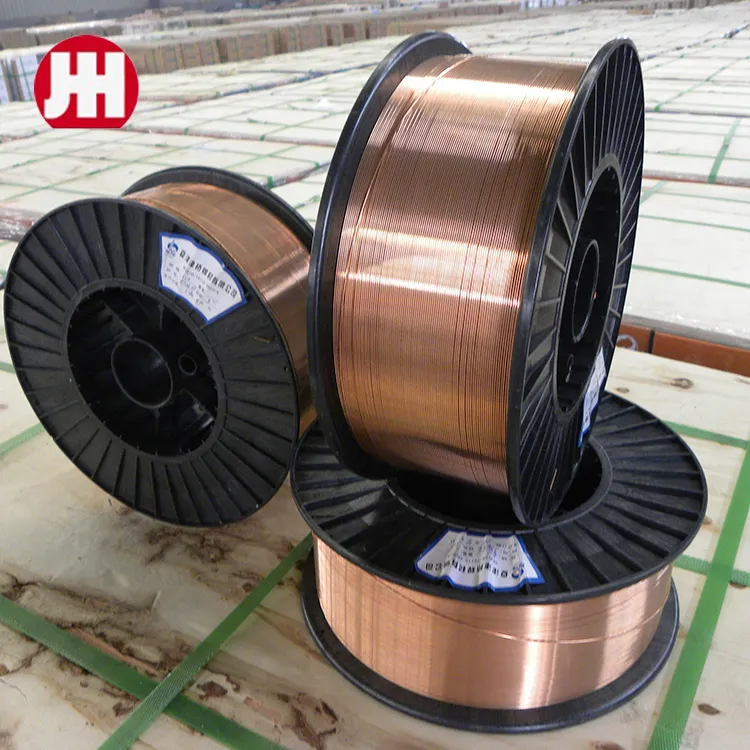

MIG solid wire is an essential tool for MIG welding, a process known for its fast and efficient results. Unlike other types of welding wires, MIG solid wire doesn’t require the use of flux, as the wire itself is designed to produce a clean, strong weld. This solid wire is made of a variety of materials, including stainless steel, mild steel, and aluminum, providing you with the flexibility to tackle a wide range of welding projects.

One of the key benefits of using MIG solid wire is its ease of use, especially for novice welders. This type of wire is easier to control than others, making it ideal for both beginners and seasoned professionals. Additionally, MIG solid wire offers excellent arc stability, producing smooth welds with minimal spatter. For applications in construction, automotive, and manufacturing, this wire is highly efficient, saving time while delivering consistent, high-quality results.

The MIG solid wire is available in various diameters, allowing you to choose the right one based on the thickness of the material you are working with. Whether you're welding sheet metal, pipes, or thicker steel sections, MIG solid wire offers a versatile solution for almost any welding application.

Vulcan ER70S-6 MIG Solid Welding Wire: A Top Choice for Consistency

When it comes to MIG welding, Vulcan ER70S-6 MIG solid welding wire is often regarded as one of the best products available. This premium quality wire is designed for use in a variety of welding processes, providing superior performance and excellent weld quality. The Vulcan ER70S-6 MIG solid welding wire is specifically formulated to deliver outstanding results when working with mild steel and carbon steel.

One of the most significant advantages of the Vulcan ER70S-6 MIG solid welding wire is its ability to create clean, spatter-free welds. The wire’s high-quality composition ensures that you get a consistent and stable arc, making it easy to produce smooth, precise welds. Whether you’re welding thin sheet metal or thicker steel structures, the Vulcan ER70S-6 MIG solid welding wire offers the performance you need to get the job done quickly and efficiently.

Additionally, the Vulcan ER70S-6 MIG solid welding wire is known for its excellent penetration, which is crucial when welding thicker materials. This wire is also highly resistant to oxidation, making it a great choice for applications in environments where the air is damp or has high humidity levels. By using the Vulcan ER70S-6 MIG solid welding wire, you can be confident that your welds will be both strong and durable, ensuring long-lasting results.

Matheson ER70S-6: The Welding Wire for Industrial-Grade Projects

The Matheson ER70S-6 welding wire is another exceptional product in the market, designed for professional welders who need top-notch performance. This welding wire is known for its ability to create smooth, clean welds with minimal spatter, making it perfect for a wide variety of industrial applications, including construction, shipbuilding, and heavy machinery repairs. The Matheson ER70S-6 welding wire is made from high-quality steel and is specifically formulated to provide excellent arc stability, deep penetration, and strong welds.

One of the standout features of the Matheson ER70S-6 welding wire is its versatility. It is suitable for welding carbon steel, mild steel, and low-alloy steel, making it an ideal choice for general-purpose welding in industries like automotive, manufacturing, and fabrication. The Matheson ER70S-6 wire also offers exceptional resistance to porosity, ensuring that your welds are clean and free from defects.

This wire’s excellent performance and consistency make it a top choice for welders who require industrial-grade materials for their projects. Whether you're welding thin sheet metal or heavier steel components, the Matheson ER70S-6 welding wire provides the strength and quality you need for long-lasting, durable welds.

ER70S-6 Welding Wire FAQs

What is the difference between the ER70S-6 TIG rod and the MIG solid wire?

The main difference lies in the type of welding process they are used for. The ER70S-6 TIG rod is used for TIG welding, which offers precise control over the weld pool, making it ideal for applications that require high-quality, clean welds. On the other hand, MIG solid wire is used in MIG welding, a faster process that is more automated and suitable for larger projects or high-production environments. Both offer excellent performance, but they are used in different welding techniques.

Can I use the Vulcan ER70S-6 MIG solid welding wire for aluminum?

No, the Vulcan ER70S-6 MIG solid welding wire is designed specifically for welding mild steel and carbon steel. If you are working with aluminum, you will need to use a different type of MIG wire, such as one made specifically for aluminum welding. The Vulcan ER70S-6 MIG solid welding wire offers excellent results for steel, but it is not suitable for aluminum applications.

Is the Matheson ER70S-6 welding wire compatible with all MIG welders?

Yes, the Matheson ER70S-6 welding wire is compatible with most MIG welding machines. However, it is always essential to check the specifications of your welder to ensure that it is capable of handling the wire size and material type you plan to use. The Matheson ER70S-6 wire is highly versatile and can be used in many welding applications, but ensuring compatibility with your equipment will help achieve the best results.

What are the advantages of using ER70S-6 over other types of welding wires?

The ER70S-6 welding wire offers excellent arc stability, low spatter, and smooth, strong welds. It is especially well-suited for welding on materials like mild steel, carbon steel, and low-alloy steel. Its ability to provide deep penetration and high-strength welds makes it a top choice for a wide range of applications. Compared to other wires, ER70S-6 offers superior performance in terms of clean welds, which is why it is commonly used in both professional and DIY welding projects.

Can I use the Vulcan ER70S-6 MIG solid welding wire for thin materials?

Yes, the Vulcan ER70S-6 MIG solid welding wire can be used for thin materials, especially with the correct settings on your MIG welder. This wire is known for its ability to produce smooth, spatter-free welds, making it suitable for both thin and thick materials. However, for very thin materials, you may want to adjust the welding parameters, such as the wire speed and heat, to ensure that you do not burn through the material.

-

What is a medium-frequency pulse? What types of welding are suitable for?BalitaNov.24,2025

-

Why is the overall cost of CO2 welding lower than that of shielded metal arc welding?BalitaNov.21,2025

-

Welding Knowledge 6BalitaNov.20,2025

-

What is a low-frequency pulse? What types of welding are they suitable for?BalitaNov.19,2025

-

Why are the weld joints from CO₂ gas shielded welding of such high quality?BalitaNov.18,2025

-

J506 Welding Rod - Low Hydrogen, All-Position, AC/DC E7016BalitaNov.17,2025