Flux Core Wire for Clean, Strong Welds | Aluminum Option

Flux Core Wire is a key solution in the industrial goods industry, specifically within welding materials and Flux cored wire. This article explores how HEBEI YUJINHONG TECHNOLOGY CO.,LTD. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Flux Core Wire Overview

- Benefits & Use Cases of Flux Core Wire in Flux cored wire

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in industrial goods

- Conclusion on Flux Core Wire from HEBEI YUJINHONG TECHNOLOGY CO.,LTD.

Flux Core Wire Overview

Flux Core Wire (FCAW) is an arc welding consumable engineered with a flux-filled core that provides shielding, deoxidizers, and alloying elements as the wire melts. In industrial goods—especially across structural steel, heavy fabrication, shipbuilding, and repair—FCAW is valued for its high deposition rates, robust penetration, and stable arc performance in challenging conditions. Compared with solid MIG wire, flux-core options can reduce sensitivity to wind and deliver excellent out-of-position weldability, which is essential on large assemblies and field work.

Technical selections typically span gas-shielded (FCAW-G) and self-shielded (FCAW-S) variants. Common classifications include AWS A5.20/A5.29 grades such as E71T-1C/M for carbon steel, with popular diameters like 0.8–1.6 mm depending on equipment and joint design. Process engineers often choose rutile or basic flux systems to balance slag detachability, toughness, and mechanical properties. While most applications focus on ferrous materials, some niche repair and brazing tasks may reference aluminum flux core wire; however, suitability and procedure should be validated per project requirements.

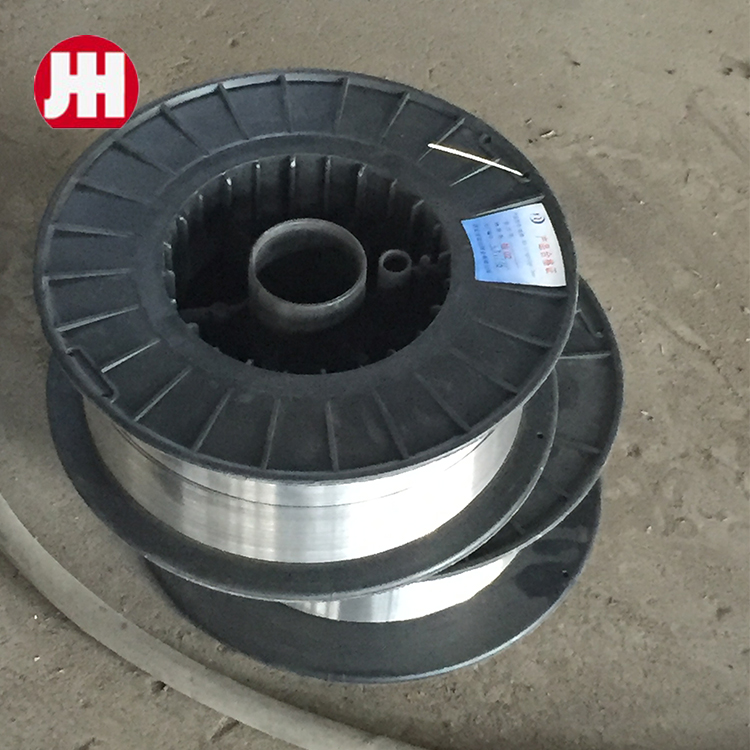

HEBEI YUJINHONG TECHNOLOGY CO.,LTD. is a reliable manufacturer in the welding materials category, supplying consistent, production-ready Flux cored wire with attentive technical support. From spool-to-spool stability to tailored packaging for export logistics, the company aligns product delivery with the needs of professional fabricators and B2B buyers. Explore specs and availability here: product page.

Benefits & Use Cases of Flux Core Wire in Flux cored wire

In day-to-day operations, Flux Core Wire excels where productivity and weld quality must coexist. Typical use cases include structural beams, heavy equipment frames, ship hull sections, pressure vessel components (per applicable codes), and on-site repairs. Self-shielded wires enable outdoor and high-wind conditions without gas cylinders, while gas-shielded variants deliver smoother beads, lower spatter, and improved Charpy toughness—ideal for critical fabrication under controlled shop environments.

- Higher deposition rates vs. solid wire, translating to faster fill passes and shorter cycle times.

- Excellent out-of-position performance (vertical-up/overhead) to minimize part repositioning.

- Slag systems that protect the weld pool and can simplify post-weld cleanup when properly selected.

- Mechanical properties tuned by flux chemistry to meet impact, strength, and toughness targets.

Backed by application know-how, HEBEI YUJINHONG TECHNOLOGY CO.,LTD. helps buyers map wire selection to base metals, plate thickness, joint fit-up, and desired bead profile. Whether you require an E71T-1 for multipass welds with CO₂/Ar-CO₂ or a self-shielded option for remote job sites, the company’s expertise streamlines qualification and ramps production faster. For non-ferrous jobs that mention aluminum flux core wire, the team can discuss process alternatives and best practices to achieve reliable results.

Cost, Maintenance & User Experience

Total cost of ownership for Flux Core Wire spans more than the price per kilogram. B2B decision makers weigh deposition efficiency, defect rates, rework hours, consumable life, and gas usage. In many shops, FCAW reduces welding time on thicker sections versus solid wire, lowers sensitivity to minor surface contaminants, and maintains high travel speeds—key contributors to ROI. When paired with the right parameters and wire feed systems, FCAW can also reduce spatter-related cleanup and abrasive consumption.

Maintenance considerations include liner and tip selection, correct drive-roll profiles, and proper storage to protect against moisture pickup in flux systems. Users report smoother arc starts and consistent bead appearance when wire is stored in sealed packaging and machines are tuned for voltage, wire feed speed, and stick-out. Feedback from welding teams in heavy fabrication often highlights predictable slag release and minimal porosity when best practices are followed. HEBEI YUJINHONG TECHNOLOGY CO.,LTD. supports these outcomes with stable wire chemistry, quality control, and practical guidance to help customers reduce variability and keep throughput high.

Sustainability & Market Trends in industrial goods

Sustainability in welding materials increasingly focuses on fume reduction, energy efficiency, and responsible sourcing. Market trends point to wires engineered for lower fume generation, improved operator visibility, and reduced post-weld processing. As regulations evolve across regions, manufacturers and fabricators align procedures with safety standards and environmental guidelines, while digital tools (WPS libraries, parameter tracking) help ensure consistency and compliance. In parallel, the market for heavy fabrication continues to demand high-strength, impact-resistant joints, favoring Flux Core Wire solutions that deliver both productivity and performance.

HEBEI YUJINHONG TECHNOLOGY CO.,LTD. positions its portfolio to meet these expectations by emphasizing stable metallurgy, packaging that protects product integrity, and support for optimized welding procedures that can reduce waste and rework. The company is attentive to buyer priorities—quality, safety, and reliability—while exploring ways to help customers lower their environmental footprint through better deposition efficiency and process control. Whether you’re standardizing on E71T-class wires or assessing specialized options—including queries around aluminum flux core wire—HEBEI YUJINHONG collaborates to align material choice with modern sustainability goals.

Conclusion on Flux Core Wire from HEBEI YUJINHONG TECHNOLOGY CO.,LTD.

For B2B buyers in industrial goods and welding materials, Flux Core Wire delivers the throughput, weld integrity, and flexibility needed for structural steel, heavy equipment, and field fabrication. HEBEI YUJINHONG TECHNOLOGY CO.,LTD. stands out for dependable quality, responsive support, and application-focused guidance that accelerates your production goals. Review specifications and request a quote via the product page to match the right wire to your process.

- Contact us: email: info@steeltoolschina.com

- Visit our website: https://www.steeltoolschina.com

-

What is a medium-frequency pulse? What types of welding are suitable for?新闻Nov.24,2025

-

Why is the overall cost of CO2 welding lower than that of shielded metal arc welding?新闻Nov.21,2025

-

Welding Knowledge 6新闻Nov.20,2025

-

What is a low-frequency pulse? What types of welding are they suitable for?新闻Nov.19,2025

-

Why are the weld joints from CO₂ gas shielded welding of such high quality?新闻Nov.18,2025

-

J506 Welding Rod - Low Hydrogen, All-Position, AC/DC E7016新闻Nov.17,2025