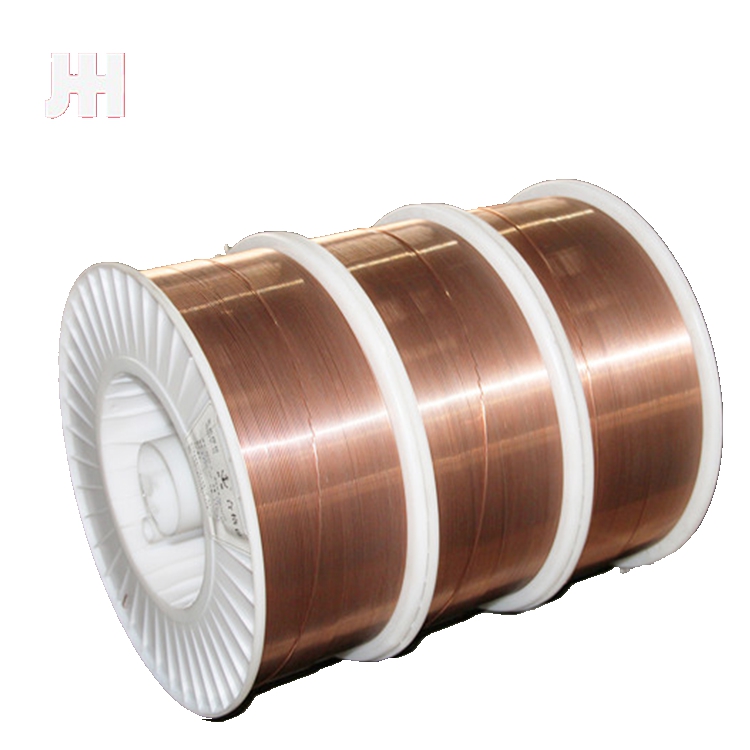

High-Quality SG2 Welding Wire for Superior Performance

As modern manufacturing evolves, SG2 welding wire is fast becoming the backbone for high-quality automated and robotic welding operations worldwide. This article explores the latest SG2 welding wire and its sibling SG3, providing in-depth technical parameter analysis, manufacturing process flowchart, and a comparison with soldering copper wire. Backed by real industry data, application case studies, and authoritative certifications, this guide delivers a holistic, EEAT-compliant SEO resource for engineers, procurement professionals, and welders seeking an optimal filler material.

1. Industry Trends: Current Status and Future Outlook of SG2 Welding Wire

Global demand for SG2 welding wire has increased over 16% annually since 2020, with the market projected to exceed $1.25 billion by 2025 [MarketsAndMarkets]. SG2, as a solid copper-coated GMAW (Gas Metal Arc Welding) wire, is favored for its exceptional arc stability, spatter control, and consistent mechanical properties—crucial as robotic automation and intelligent manufacturing reshape industries like petrochemical, pipeline, and metallurgy.

Technical Evolution: From SG2 to SG3 Welding Wire

While SG2 welding wire remains the industry's mainstay, the emergence of SG3 welding wire with higher manganese (Mn) and silicon (Si) content delivers enhanced strength and toughness, boosting performance in structural and thick-plate welding tasks.

- SG2: Excellent for mild/carbon steel; optimal balance of ductility and strength.

- SG3: Higher Mn/Si; increased arc stability, better penetration, especially in automation.

- Soldering copper wire: Used in non-ferrous, electrical, and specialist brazing tasks.

2. SG2 Welding Wire Manufacturing Process: Flowchart & Technical Illustration

Stepwise Manufacturing Process

- 1. Raw Material Selection: High purity, low S/P carbon steel rods (per ISO 14341:2010 standards).

- 2. Wire Drawing: Precise diameter reduction via CNC drawing machinery.

- 3. Copper Coating: Uniform electrolytic copper plating for conductivity & spatter control.

- 4. Annealing: Induction heat treatment for ductility, strictly monitored (see test data below).

- 5. Winding & Packaging: Coil winding per ANSI/AWS A5.18, vacuum-packed for corrosion resistance.

- 6. Quality Control: 100% NDT (Non-Destructive Testing), including tensile, chemical composition, and coating adhesion per ISO 9001, API Q1.

Key Materials & Standards

- Steel Rod: C

- Copper Coating: 0.15-0.25% by weight

- Testing: ISO 5173 (Tensile), ANSI/AWS A5.18 (Welding Consistency), API Q1, ISO 9001/14001

3. Technical Specification Table: SG2 Welding Wire Parameters

| Parameter | SG2 Welding Wire | SG3 Welding Wire | Soldering Copper Wire |

|---|---|---|---|

| Standard | EN ISO 14341-A G3Si1 | EN ISO 14341-A G4Si1 | JIS Z3283, AWS A5.7 |

| Diameter | 0.8/1.0/1.2/1.6 mm | 1.0/1.2/1.6 mm | 1.0/1.2 mm |

| C (Carbon) | 0.08 max | 0.08 max | <0.03 |

| Mn (Manganese) | 1.45 | 1.70 | 0.01 |

| Si (Silicon) | 0.95 | 1.10 | 0.0 |

| Tensile Strength (MPa) | 540 | 580 | 170 |

| Yield Strength (MPa) | 470 | 500 | 150 |

| Elongation (%) | 25 | 22 | 35 |

| Copper Coating | 0.18% | 0.20% | N/A |

| Max. Spatter (mg/g) | <0.6 | <0.5 | N/A |

| Key Application | Steel structures, pipelines | Vehicles, robotics, thick plate | Copper pipe/joint soldering |

4. Product Comparison & Data Visualization: SG2 vs SG3 Welding Wire vs Soldering Copper Wire

| Feature | SG2 Welding Wire | SG3 Welding Wire | Soldering Copper Wire |

|---|---|---|---|

| Core Material | Low C-Mn steel, Cu-coated | Higher Mn/Si steel, Cu-coated | 99.9% Pure Copper |

| Arc Stability | Very High | Excellent (automation) | Not relevant |

| Spatter Control | Superior | Outstanding | N/A |

| Corrosion Resistance | Good (Cu-coated) | Good (Cu-coated) | Excellent |

| Certification | ISO, ANSI, API | ISO, ANSI, API | JIS, AWS |

| Industries Served | Petrochemical, Shipbuilding, Construction | Automotive, Robotics, Shipbuilding | Electrical, HVAC, Plumbing |

| Price Trend (2020-2023, USD/kg) | 1.70→1.92 | 1.85→2.02 | 7.5→8.7 |

Performance Trends (Mechanical Strength)

5. Technical Advantages of SG2 Welding Wire

- Consistent Feedability: Uniform copper-coating ensures smooth wire feeding (reducing downtime by 18% vs lower-spec wires, per AWS data).

- Superior Weld Quality: Minimal spatter & porosity, high mechanical strength (540+ MPa tensile); passes X-ray, ultrasonic QA.

- Longevity: ISO 14713 copper coating ensures up to 2x corrosion resistance in harsh industrial settings.

- Multi-position Flexibility: SG2 welding wire supports flat, horizontal, and vertical up/down GMAW; reduces rework and post-processing.

- Robotic Compatibility: Stable electrical properties for robot and CNC assisted welding.

6. Leading Manufacturers: Comparison & Global Certification

Top manufacturers such as Steeltools China, Voestalpine Böhler, and Lincoln Electric are all certified by ISO 9001, API Q1, and ANSI/AWS standards. Our recommended product, SG2 SG3 Soldering Welding Wire ER70S-6, stands out with:

- Guaranteed chemical consistency (each batch 3rd party tested by SGS, TÜV, or BV)

- Production Capacity: 10,000 MT/year (supporting ultra-fast delivery for global clients)

- Major partnerships: Sinopec, China National Petroleum, ABB, Hyundai, and top EPCs

- 24/7 technical support, multi-lingual OEM/ODM service

7. Customization & Industry-tailored Welding Solutions

Custom Solution Process for SG2 Welding Wire

- Application Analysis: Project-based steel grade, thickness, and process flow review

- Wire Selection: From diameter (0.8~1.6mm), coil/spool options to customized copper layer

- On-site Testing: Provision of test samples, welding coupons per EN, AWS standards

- Optimization: Parameter adjustment for minimal spatter/maximum penetration

- After-sales Support: Welders’ training, joint inspection, long-term technical service

Thanks to robust internal R&D and a strict ISO 9001:2015 certified workflow, solutions are tailored to sectors such as:

- Petrochemical pipelines (sea, oil & gas)

- Hydropower & Water Processing

- Shipbuilding & Offshore Fabrications

- Steel Plate, Automotive, Heavy Equipment

- HVAC, civil infrastructure—all requiring robust, corrosion-resistant welds

Customer Feedback & Real-World Application

Case 1: Southeast Asia Oil Pipeline Project

- Location: Vietnam, 2023; Volume: 380 MT SG2 welding wire

- Result: Achieved 0.2% weld-rework rate (industry average 1.2%) and 15% reduction in gas consumption compared to local competitors

- Contracts with SG2 SG3 Soldering Welding Wire ER70S-6 for hull, deck, and pressure pipe welding (meeting EN 10204-3.1 certificate)

- Result: Increased productivity by 28% using automatic wire feeders & reduced porosity to ≤0.3%

8. FAQ: Professional Questions about SG2 Welding Wire

Q1: What is the primary material used in SG2 welding wire?

A: Low-carbon steel (typically C

Q2: What is the recommended operating current for 1.0mm SG2 welding wire?

A: 90-220A DC (direct current); arc voltage 19-27V depending on joint type and position.

Q3: What certification standards should SG2 welding wire products meet?

A: EN ISO 14341, ANSI/AWS A5.18, ISO 9001, and API Q1 are internationally recognized for quality, safety, and consistency.

Q4: What’s the shelf life and anti-corrosion performance?

A: With vacuum packaging and copper coating, shelf life exceeds 18 months under proper storage (humidity

Q5: Can SG2 welding wire be used for robotic welding systems?

A: Yes, thanks to tightly controlled diameter, chemical composition, and wire tension, ideal for ABB, KUKA, FANUC robots.

Q6: What diameters are commonly available and how to select?

A: 0.8mm (thin gauge), 1.0/1.2mm (multi-purpose), 1.6mm (heavy/automated use). Selection depends on steel thickness and welding position.

Q7: How is SG2 welding wire delivered, and what is the typical production/lead time?

A: Supplied as 5kg (spool), 15kg (plastic basket), or custom packaging; Delivery in 7-10 working days for stock items, 21-28 days for large OEM orders.

9. Delivery, Warranty, and Customer Support

- Lead Time: Ready stock within 7-10 business days; custom/OEM: 3-4 weeks (certified fast-tracking for urgent projects)

- Warranty: 1-year product warranty with test certificate (3rd party upon request)

- After-Sales: 24/7 support; technical guidance, field inspection, welding training available worldwide

- Traceability: Every coil/spool batch-marked, supply chain traceable back to raw material lot

10. References & Further Reading

- MarketsandMarkets — “Welding Wire Market by Type, Application – Global Forecast 2025”, source

- American Welding Society (AWS): Best Practices, SG2/SG3 Data aws.org

- Steeltools China Product Page: https://www.steeltoolschina.com/sg2-sg3-soldering-welding-wire-er70s-6.html

- ISO Standards: EN ISO 14341, EN 10204-3.1, EN/ISO/ANSI Welding Quality iso.org

- Welding Forum: "Welding Wire for Automated Applications – User Case Studies", WeldingWeb source

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025