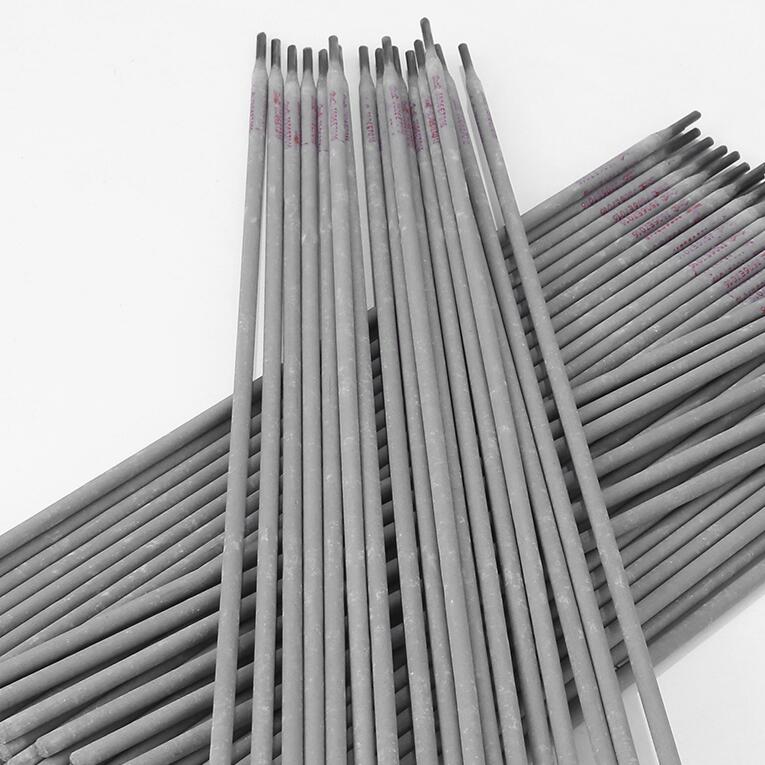

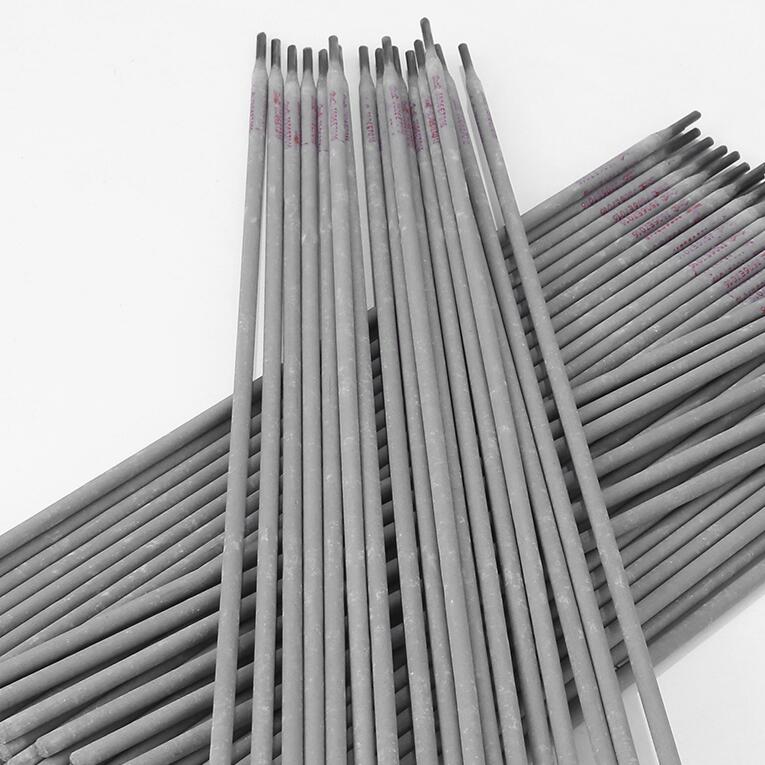

The welding industry is constantly evolving, driven by the demands for durability, safety, and high performance across steel structures. e7016 welding rods play a pivotal role in delivering reliable joints in heavy industries. This in-depth article consolidates the latest industry data, technical insights, manufacturing processes, and real-world applications, enhancing your understanding and trust in e7016 welding rods.

1. Industry Overview & Market Trends

The demand for high-efficiency low-hydrogen covered electrodes such as e7016 welding rods continues to grow, supported by global infrastructure projects, energy sector upgrades, and advancements in metalworking. According to the latest MarketsandMarkets® welding materials report, the global electrode market is expected to reach USD 20.1 billion by 2028, with E7016 class rods comprising ~15% of all ferritic electrode consumption.

- Industry Share: Oil & Gas (32%), Shipbuilding (18%), Power Generation (20%), Construction (15%), Others (15%+).

- Growth Factors: Stricter welding quality standards (ISO 2560, AWS A5.1), increased usage in pressure vessels, and energy-efficient steelwork solutions.

2. Technical Parameters of e7016 welding rods

The e7016 welding rods stand out for their excellent arc stability, minimal spatter, and high mechanical strength. Below is a summarized table of the typical properties, compared with industry equivalents.

| Parameter |

e7016 Welding Rods |

Electrode 7016 |

General E7018 |

| Chemical Composition (wt.%) |

Fe: Bal., C: 0.12, Mn: 0.60, S: 0.025, P: 0.020 |

Fe: Bal., C: 0.13, Mn: 0.70 |

Fe: Bal., C: 0.15, Mn: 0.80 |

| Tensile Strength (MPa) |

≥ 500 |

≥ 480 |

≥ 490 |

| Yield Strength (MPa) |

≥ 400 |

≥ 390 |

≥ 390 |

| Elongation (%) |

≥ 22 |

≥ 20 |

≥ 18 |

| Impact Toughness (J, -30°C) |

≥ 47 |

≥ 41 |

≥ 39 |

| Covering Type |

Low Hydrogen, Rutile Base |

Low Hydrogen, Rutile Base |

Low Hydrogen, Rutile Base |

| Standard |

AWS A5.1, ISO 2560-A |

AWS A5.1 |

AWS A5.1 |

3. Manufacturing Process – Explained

Raw Material Selection

Select high-purity iron powder, manganese, and alloying agents, conforming to ISO 2560 & ANSI/AWS A5.1 standard.

→

Coating Formulation

Blend precise ratios of low-hydrogen minerals & rutile to form electrode coating. Monitored for homogeneity and reactivity.

→

Core Wire Preparation

High carbon steel or mild steel drawn to diameter; surface cleaned for optimal coating adherence.

→

Extrusion & Baking

Mineral coating extruded onto core wire, then oven-baked (300~400°C) to remove residual moisture and ensure stable arc.

→

Quality Testing

Mechanical, chemical, and nondestructive tests following ISO 14341 & AWS protocols.

Note: Each batch is X-ray, tensile, and impact tested for

full compliance with ASME IX and ISO requirements (Ref:

WeldingInsider Article).

4. Product Specifications & Technical Advantages

- Diameter: 2.5/3.2/4.0/5.0mm (±0.05mm tolerance)

- Length: 300mm, 350mm, 400mm

- Welding Position: All position (1G/2G/3G/4G)

- Arc Stability: Excellent, smooth arc characteristics & easy slag removal

- Hydrogen Content: ≤4 ml/100g deposited metal (low hydrogen, reduced risk of cold cracking)

- ISO 2560-A Certified

- Service Life: Designed for >20 years in controlled installations

These technical advantages, attested by international clients, have positioned e7016 welding rods as the prime option for critical steel joints in demanding sectors.

5. Industry Comparison Chart – e7016 Welding Rods vs Alternatives

| Feature |

e7016 Welding Rods |

E6013 |

E7018 |

| Position |

All Position |

Flat/Horizontal only |

All Position |

| Hydrogen Control |

Low (≤4ml/100g) |

Moderate |

Extra-Low (≤3ml/100g) |

| Impact Resistance (-30°C) |

High (~47J) |

Moderate |

High |

| Slag Removal |

Easy |

Moderate |

Easy |

| Application |

Bridges, Pipelines, Boilers, Pressure Vessels |

General Fabrication |

Heavy Structures |

| Price Level |

Mid |

Low |

High |

6. Customization Solutions & Delivery Flow

- Diameter/Length Customization: According to project specs (2.5-6.0mm × 250-500mm)

- Branding: OEM services available with private logo/printing

- Packing: Waterproof carton, vacuum bags (per ISO/EN standards)

- Lead Time: Typical delivery within 12~17 days post order confirmation

- Quality Assurance: Each batch shipped with inspection certificates (ISO 9001, SGS audited)

- Support: 24/7 technical consulting; on-site application training on request

7. Typical Application Scenarios & Case Studies

e7016 welding rods are widely deployed in:

- Oil & gas pipeline welding/repair

- Petrochemical structural fabrication

- Water treatment & hydropower reservoirs

- Ship hulls, pressure vessels, and bridge construction

- Boiler and heavy machinery structural repair

Customer Case: Saudi Arabia 2021 Oil Facility Pipeline Weld

- Background: Aramco's pipeline extension project required >280km of high-toughness weld with minimal cold-cracking risk under extreme temperature swings (from +45°C to -10°C).

- Solution: Adopted e7016 welding rods (3.2mm, 350mm), supplied by STEELTOOLSCHINA. On-site preheating and strict rod baking ensured hydrogen level < 3.3ml/100g.

- Impact: 99.7% X-ray pass rate, steel joint tensile ≥515MPa, weld integrity maintained after 18 months of service, saving ~$480,000 in repairs compared to previous consumables.

User Feedback: Hungary Hydro Plant Maintenance

- Installed in January 2023 for sudden turbine pressure vessel repair.

- All-position welding achieved ISO 9606-1 certified performance.

- No hydrogen-induced cracking after 6 months; client cited "clean arc and easy slag peel-off even in overhead position."

8. Authoritativeness & Certifications

- 20+ years manufacturing experience of electrodes for steel structure welding

- Certified under ISO 9001:2015, AWS standards

- Long-term supply for global clients: Siemens, Aramco, Shanghai Metro, Vietnam Shipyards, SABIC, PowerChina

- Products independently tested & approved by SGS, TÜV Rheinland

- Meets all major industry criteria: ISO 2560-A, EN 499, AWS A5.1, ASME IX

9. Professional FAQ – e7016 welding rods, Electrode 7016 & Welding Electrode 7016

Q1: What material composition defines e7016 welding rods?

A: The core is typically a mild steel wire (C ≤0.12%; Mn ~0.6%), covered with a low-hydrogen, rutile-based flux system incorporating minor alloying elements for enhanced impact resistance and arc stability.

Q2: Which international standards does electrode 7016 comply with?

A: Electrode 7016 adheres to AWS A5.1 (USA), ISO 2560-A (global), and EN 499 (Europe), ensuring cross-border usability and safety.

Q3: What is the recommended storage and baking procedure for e7016 welding rods?

A: Store below 60% relative humidity; bake at 350–400°C for 1 hour before use to prevent hydrogen pickup (as per ISO/TR 17671 & supplier guidelines).

Q4: What is the typical diameter and current range for welding electrode 7016?

A: Diameter options are 2.5/3.2/4.0/5.0mm; recommended current ranges from 70A (2.5mm) to 150A (5.0mm), depending on welding position and technique.

Q5: In which scenarios is e7016 welding rods preferred?

A: Used in critical steel joints, pipelines, boiler fabrication, and pressure vessels where superior notch toughness, X-ray integrity, and low diffusible hydrogen are required.

Q6: How does e7016 compare with E6013 in terms of weld quality?

A: E7016 delivers higher tensile strength, ductility, and lower risk of cold cracking. E6013 is more suitable for light fabrication with less demanding mechanical requirements.

Q7: What is the shelf life and warranty policy?

A: Shelf life is up to 24 months under original packaging and proper storage. Supplier warranty covers batch conformity, mechanical properties, and consistency as per ISO 9001:2015 protocols.

Q8: Can e7016 welding rods be customized for anti-corrosion or offshore standards?

A: Yes. Customized alloying in the flux and additional manganese/chromium content can be formulated for optimized anti-corrosive property, fitting offshore or aggressive chemical environments.

10. Delivery, Warranty & Customer Support

- Delivery Time: 12-17 days (standard), with global air/sea freight logistics partners.

- Warranty: Full batch traceability; replacement/refund for any accredited non-conformity under ISO/AWS standards.

- Support: Pre/post-sale consultation, on-site guidance, and continuous technical support. Contact via WhatsApp, email, or hotline (24/7 response).

- Certifications: All goods bear ISO9001:2015, SGS test reports, and can be double-inspected before shipment (client welcome).

11. References & Authoritative Links