E71T-1 Shielding Gas & Cored Wire: Maximize Weld Quality

Industry Trends in Flux-Cored Arc Welding and E71T-1 Applications

The global welding industry is undergoing significant transformation, driven by demands for increased productivity, enhanced quality, and reduced operational costs. In this landscape, Flux-Cored Arc Welding (FCAW) has emerged as a cornerstone process, particularly for heavy fabrication, structural steel, and shipbuilding. Its inherent advantages, such as high deposition rates, excellent weld metal properties, and adaptability to various welding positions, make it indispensable for modern industrial applications. A key component of this evolution is the continued refinement and application of specific wire types, with e71t 1 shielding gas applications standing out as a critical area of focus. This specific classification, E71T-1, refers to a flux-cored wire designed for all-position welding with CO2 shielding gas, known for its deep penetration, consistent bead appearance, and mechanical strength suitable for demanding structural work.

Current industry trends indicate a growing preference for solutions that optimize workflow and minimize rework. The versatility of e71t 1 shielding gas combined with gas shielded cored wire addresses these needs by offering superior arc stability, reduced spatter, and improved slag detachability compared to other welding processes. Furthermore, the push towards automation and robotic welding systems has amplified the demand for highly consistent and reliable consumables like E71T-1C, ensuring repeatable quality and efficiency in high-volume production environments. Manufacturers are continually innovating to enhance the wire's performance characteristics, including impact toughness, low-temperature properties, and resistance to porosity, to meet increasingly stringent engineering specifications across various sectors.

Manufacturing Process: E71T-1C Gas Shield Flux Coated Welding Wire

The production of high-quality E71T-1C gas shielded cored wire, essential for optimal performance with e71t 1 shielding gas, is a sophisticated multi-stage process ensuring precision and consistency. This manufacturing journey transforms raw materials into a highly engineered welding consumable.

Schematic Steps of Wire Production:

- Raw Material Selection: High-purity steel strips (typically low carbon steel) are meticulously selected for their metallurgical composition, ensuring optimal ductility and strength. Fluxing agents, including deoxidizers, slag formers, arc stabilizers, and alloying elements, are sourced to precise specifications.

- Strip Forming: The steel strip undergoes a series of precision rolling operations, forming it into a U-shaped channel. This initial forming is critical for accurate flux retention.

- Flux Filling: The core of the wire is then filled with a carefully measured quantity of powdered flux. The composition of this flux is proprietary and engineered to provide the desired mechanical properties, arc characteristics, and slag system when combined with e71t 1 shielding gas.

- Wire Closing and Drawing: After flux filling, the U-shaped strip is closed into a tubular form, and its edges are continuously seamed. This tube is then cold-drawn through a series of dies, gradually reducing its diameter to the final gauge (e.g., 1.2mm, 1.6mm). This drawing process compacts the flux, hardens the wire, and ensures a uniform cross-section.

- Copper Coating (Optional but common): For enhanced electrical conductivity, corrosion resistance, and improved wire feeding, many E71T-1C wires receive a thin copper coating through an electrolytic process.

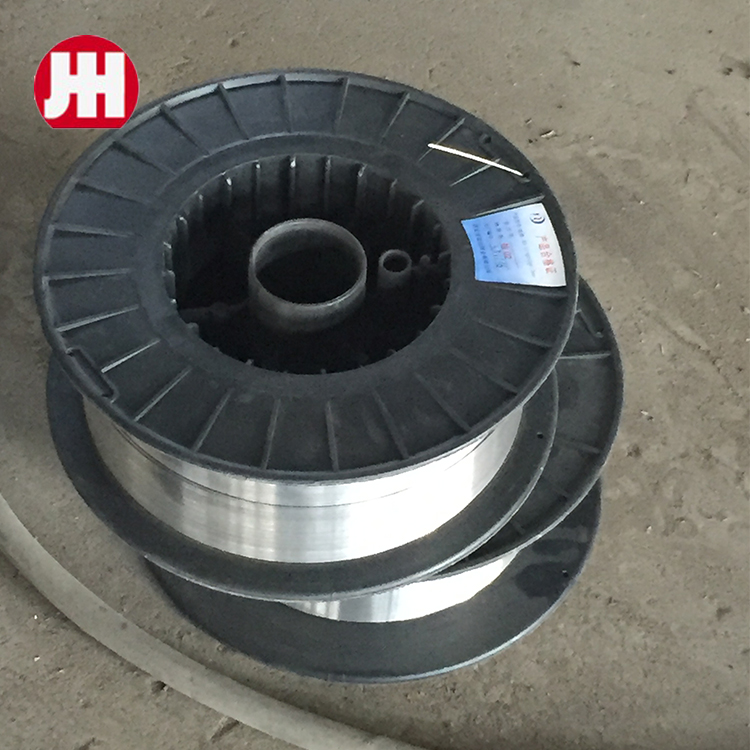

- Spooling and Packaging: The finished wire is precisely spooled onto various reel sizes (e.g., 15kg, 20kg spools) and hermetically sealed in moisture-resistant packaging to prevent atmospheric contamination.

Testing Standards: Throughout and after the manufacturing process, the wire undergoes rigorous testing to meet international standards such as AWS A5.20/A5.20M (E71T-1C classification), ISO 17632-A (T 42 2 P C 2 H5), and other relevant certifications (e.g., ABS, DNV, LR). These tests include chemical analysis of the weld metal, mechanical property tests (tensile strength, yield strength, elongation, impact toughness), and radiographic examination for internal soundness. Our commitment to these standards ensures the reliability and performance of our gas shielded cored wire products.

Service Life & Target Industries: The service life of weldments created with E71T-1C wire using e71t 1 shielding gas is exceptionally long when properly applied, often exceeding several decades in demanding environments. Our products primarily serve target industries such as:

- Petrochemical & Energy: For pipelines, pressure vessels, and offshore structures where high strength and integrity are paramount.

- Construction & Metallurgy: In structural steel fabrication for buildings, bridges, and heavy machinery, ensuring robust and durable joints.

- Shipbuilding: For hull construction, deck assemblies, and other marine applications requiring high deposition rates and all-position capabilities.

- Water Supply & Drainage: For the fabrication of large diameter pipes and infrastructure where consistent quality and corrosion resistance are critical.

Demonstrated Advantages: In typical application scenarios, E71T-1C wire offers significant advantages:

- Energy Saving: High deposition rates translate to fewer passes and shorter arc-on time, reducing energy consumption per unit of weld metal.

- Corrosion Resistance: Engineered flux formulations and weld metal chemistry provide enhanced resistance to various corrosive environments, extending the lifespan of welded structures.

- High Productivity: Excellent wire feedability, stable arc, and minimal spatter contribute to higher operational efficiency and less post-weld cleaning.

Technical Specifications and Parameters for E71T-1C

Understanding the technical specifications of E71T-1C gas shielded cored wire is crucial for engineers and procurement specialists to ensure optimal performance for applications requiring e71t 1 shielding gas. The parameters below reflect typical values for a premium E71T-1C wire, highlighting its robust metallurgical and mechanical properties.

Typical Chemical Composition of Weld Metal (wt.%)

| Element | E71T-1C (Typical) | AWS A5.20 Max. |

|---|---|---|

| Carbon (C) | 0.05 - 0.12 | 0.12 |

| Manganese (Mn) | 1.00 - 1.60 | 1.75 |

| Silicon (Si) | 0.30 - 0.60 | 0.90 |

| Phosphorus (P) | 0.010 - 0.020 | 0.030 |

| Sulfur (S) | 0.008 - 0.015 | 0.030 |

| Nickel (Ni) | < 0.10 | 0.50 |

| Chromium (Cr) | < 0.15 | 0.20 |

Typical Mechanical Properties of Weld Metal (As-Welded)

| Property | E71T-1C (Typical) | AWS A5.20 Min. |

|---|---|---|

| Tensile Strength (MPa) | 520 - 580 | 490 (70 ksi) |

| Yield Strength (MPa) | 420 - 480 | 390 (58 ksi) |

| Elongation (%) | 24 - 30 | 22 |

| Charpy V-notch Impact at -20°C (J) | > 47 | 27 (20 ft-lb) |

These robust mechanical properties, particularly high tensile strength and excellent impact toughness at low temperatures, affirm the suitability of E71T-1C wire for critical structural applications. The controlled chemistry ensures good resistance to hydrogen-induced cracking and consistent metallurgical integrity, which are paramount in construction, shipbuilding, and heavy machinery fabrication.

Application Scenarios for E71T-1C with CO2 Shielding Gas

The versatility and superior performance of E71T-1C gas shielded cored wire, when paired with the correct e71t 1 shielding gas (typically 100% CO2), make it a preferred choice across a broad spectrum of industrial applications. Its ability to perform in all positions (flat, horizontal, vertical-up, overhead) further enhances its utility.

- Structural Steel Fabrication: E71T-1C is extensively used for welding structural components in buildings, bridges, and other civil infrastructure projects. Its high deposition rates accelerate construction, while its excellent mechanical properties ensure the integrity and longevity of load-bearing structures.

- Shipbuilding and Marine Applications: The shipbuilding industry benefits greatly from E71T-1C's all-position capability and robust weld quality. It is used for welding hull sections, deck plating, bulkheads, and other critical maritime structures, providing resistance to fatigue and harsh marine environments.

- Heavy Equipment Manufacturing: Manufacturers of excavators, cranes, agricultural machinery, and other heavy equipment rely on E71T-1C for welding components that must withstand significant dynamic stresses and abrasive conditions.

- Pressure Vessels and Storage Tanks: For applications requiring high-integrity welds, such as pressure vessels, boilers, and large storage tanks in the petrochemical and power generation industries, E71T-1C provides the necessary strength and resistance to internal pressures and varying temperatures.

- Pipe Fabrication: In both onshore and offshore pipeline projects, E71T-1C offers excellent root pass and fill pass capabilities, ensuring defect-free welds in critical joints that must withstand high pressures and corrosive media.

- General Fabrication: From automotive frame components to railcar manufacturing and general repair work, E71T-1C offers a highly adaptable solution for a wide range of mild and medium strength steel joining tasks.

The robust slag system provided by the flux core, combined with the protective envelope of e71t 1 shielding gas, facilitates easy slag removal and produces a clean, aesthetically pleasing weld bead, minimizing post-weld finishing efforts. This translates directly to increased productivity and reduced labor costs for fabricators.

Technical Advantages of E71T-1C Gas Shielded Cored Wire

The adoption of E71T-1C gas shielded cored wire, particularly with appropriate e71t 1 shielding gas, brings a multitude of technical advantages that directly impact operational efficiency, weld quality, and cost-effectiveness for B2B clients.

- High Deposition Rates: FCAW, specifically with E71T-1C, inherently offers significantly higher deposition rates compared to Solid Wire (GMAW) and Shielded Metal Arc Welding (SMAW). This means faster welding speeds and fewer passes required for larger welds, dramatically boosting productivity and reducing labor time.

- Excellent All-Position Weldability: The E71T-1C classification denotes its capability for all-position welding (flat, horizontal, vertical-up, overhead). This flexibility is critical for complex fabrications and field erection, where component orientation cannot always be optimized for downhand welding.

- Deep Penetration and Robust Weld Profile: The arc characteristics and flux system of E71T-1C produce deep and consistent penetration, resulting in strong, sound welds even in challenging joint configurations. The weld bead is typically smooth with minimal undercut, requiring less post-weld grinding.

- Superior Weld Metal Properties: The precisely engineered flux core introduces deoxidizers and alloying elements that enhance the mechanical properties of the weld metal, including high tensile and yield strength, excellent toughness, and improved resistance to porosity and cracking, even in environments with some contamination.

- Consistent Arc Stability and Low Spatter: The interaction between the flux, wire, and e71t 1 shielding gas (CO2) contributes to a stable arc, which reduces spatter generation. This minimizes clean-up time and material waste, leading to a more efficient and cleaner welding process.

- Ease of Slag Removal: The self-peeling or easily removable slag ensures minimal effort in post-weld cleaning, another significant factor in improving overall productivity and reducing operational costs.

- Adaptability to Outdoor Conditions: The flux-cored wire is less susceptible to wind interference compared to solid wire GMAW, making it more suitable for outdoor or draughty indoor welding environments without compromising shield gas integrity.

Vendor Comparison and Customized Solutions

When selecting a supplier for E71T-1C gas shielded cored wire and related e71t 1 shielding gas solutions, B2B decision-makers must consider several critical factors beyond just price. A thorough vendor comparison should evaluate aspects that impact long-term operational efficiency, quality, and supply chain reliability.

Key Vendor Comparison Criteria:

- Product Quality & Consistency: Verify compliance with international standards (AWS, ISO, CE) and review batch-to-batch consistency. Requesting certifications and test reports (MTRs) is crucial. A reliable vendor will have stringent quality control protocols throughout their manufacturing process.

- Technical Support & Expertise: Assess the vendor's ability to provide pre-sales consultation and post-sales technical support. This includes assistance with welding procedure specification (WPS) development, troubleshooting, and optimization of welding parameters for your specific applications.

- Supply Chain Reliability: Evaluate lead times, inventory management, and logistical capabilities. A robust supply chain ensures timely delivery, minimizing downtime in your production schedule.

- Innovation & R&D: Leading vendors invest in research and development to offer improved products (e.g., enhanced impact toughness, better arc characteristics, specialized wires for particular base metals) and to stay ahead of industry demands.

- Certifications & Authorizations: Look for vendors with industry-recognized certifications (e.g., ISO 9001 for quality management) and product approvals from major classification societies (e.g., ABS, Lloyd's Register, DNV-GL).

Customized Solutions:

While E71T-1C is a standardized product, reputable suppliers can offer customized solutions to address unique client requirements. This could include:

- Tailored Packaging: Custom spool sizes or bulk packaging options to integrate seamlessly with specific automated welding setups or to optimize material handling.

- Specific Chemical Composition Adjustments: For highly specialized applications, minor adjustments to flux formulation might be made to achieve particular weld metal properties (e.g., enhanced corrosion resistance for specific chemical environments, or fine-tuning for specific base metal grades).

- Optimized Wire Feeding Properties: Working with clients to adjust wire surface finish or copper coating thickness to improve feedability through long conduits in robotic welding systems.

- Joint R&D Programs: Collaborating on the development of new consumables for emerging applications or challenging material combinations.

Choosing a vendor that can provide both standardized excellence and bespoke solutions ensures that your welding operations are equipped with the most efficient and effective consumables for any project scale or complexity, including specialized requirements for e71t 1 shielding gas applications.

Application Case Studies

Real-world applications demonstrate the tangible benefits of utilizing E71T-1C gas shielded cored wire with e71t 1 shielding gas in demanding industrial contexts.

Case Study 1: Large-Scale Bridge Construction

A major infrastructure project involving the construction of a new suspension bridge required high-strength, all-position welding solutions for the fabrication of massive steel girders and tower sections. The client, a leading construction firm, chose E71T-1C wire due to its proven track record in heavy structural applications. By leveraging the high deposition rates of E71T-1C with CO2 shielding gas, the fabricators achieved a 30% increase in welding productivity compared to their previous GMAW solid wire processes. The excellent mechanical properties of the weld metal ensured compliance with stringent structural integrity requirements, while the robust slag system allowed for minimal interpass cleaning, further accelerating the project timeline. This successful deployment underscored the efficiency and reliability of e71t 1 shielding gas in critical infrastructure.

Case Study 2: Offshore Platform Fabrication

For the fabrication of a complex offshore oil platform in a challenging marine environment, a specialized engineering firm required welding consumables that offered exceptional low-temperature impact toughness and resistance to hydrogen-induced cracking. E71T-1C gas shielded cored wire, specifically engineered for superior impact properties at -20°C, was selected. The wire performed exceptionally well in both shop fabrication and field erection, where positional welding was common. Welders reported excellent arc characteristics and good bead appearance even in windy conditions, thanks to the robust flux and e71t 1 shielding gas. The welds consistently passed rigorous non-destructive testing (NDT) including ultrasonic and radiographic examinations, ensuring the structural integrity of the platform against harsh oceanic forces. This project highlighted the wire's reliability in extreme conditions.

Case Study 3: Robotic Welding in Automotive Manufacturing

An automotive manufacturer transitioning to fully automated robotic welding cells for chassis components sought a high-performance gas shielded cored wire that would ensure consistent quality and high deposition rates in a repetitive manufacturing environment. Our E71T-1C wire was integrated into their robotic systems. The wire's consistent diameter and surface finish ensured smooth feeding through automated torches, minimizing wire feeding issues and downtime. The stable arc and minimal spatter produced by the E71T-1C with its dedicated e71t 1 shielding gas allowed for reduced post-weld cleaning, significantly lowering cycle times and improving throughput. The manufacturer achieved a notable increase in production speed and a reduction in defect rates, validating the wire's suitability for advanced automation.

Trustworthiness, Support, and Guarantees

Establishing and maintaining trust is paramount in B2B relationships. We are committed to providing comprehensive support and clear commitments to our clients, ensuring peace of mind when investing in our E71T-1C gas shielded cored wire and related e71t 1 shielding gas solutions.

Frequently Asked Questions (FAQ)

Q1: What is the recommended shielding gas for E71T-1C wire?

A1: E71T-1C specifically requires 100% CO2 as its shielding gas to achieve optimal mechanical properties and arc characteristics.

Q2: Can E71T-1C be used for all-position welding?

A2: Yes, the '1' in E71T-1 indicates that it is designed for all-position welding, including flat, horizontal, vertical-up, and overhead.

Q3: What are the primary advantages of E71T-1C over solid wire (GMAW) for structural welding?

A3: E71T-1C offers significantly higher deposition rates, better penetration, and is more tolerant to mill scale and surface contaminants. Its flux system also provides superior weld metal properties and a more stable arc in varied conditions.

Q4: What base metals are suitable for welding with E71T-1C?

A4: It is primarily used for welding mild and medium carbon steels, including ASTM A36, A283, A572, and various shipbuilding steels.

Lead Time and Fulfillment

We maintain robust inventory levels for standard E71T-1C wire sizes and facilitate efficient logistics to ensure prompt delivery. Typical lead times for in-stock items range from 3-7 business days within regional distribution networks, with international shipments varying based on destination and shipping method. For large volume orders or customized solutions, our sales team will provide precise lead time estimates and work closely with you to meet your project timelines.

Warranty Commitments

Our E71T-1C gas shielded cored wire is manufactured under stringent quality control and comes with a full material and performance warranty against manufacturing defects. We guarantee that our products will meet or exceed all specified AWS A5.20/A5.20M (E71T-1C) and ISO 17632-A standards for chemical composition and mechanical properties when used as recommended with the appropriate e71t 1 shielding gas. Should any product fail to meet these specifications, we commit to prompt replacement or credit, subject to our standard terms and conditions.

Customer Support and After-Sales Service

Our dedication to client success extends beyond the point of sale. We offer comprehensive after-sales support, including a dedicated technical service team available to assist with:

- Welding procedure optimization and parameter guidance.

- Troubleshooting welding issues related to consumables.

- On-site technical visits for complex challenges.

- Product training and workshops for your welding personnel.

We value long-term partnerships and are committed to ensuring your welding operations run smoothly and efficiently with our high-quality consumables.

Authoritative References

- American Welding Society (AWS) A5.20/A5.20M:2020, Specification for Carbon Steel Electrodes for Flux Cored Arc Welding.

- ISO 17632-A:2015, Welding consumables - Tubular cored electrodes for gas shielded and non-gas shielded metal arc welding of non-alloy and fine grain steels - Classification.

- The Welding Institute (TWI) - Technical Knowledge Base on Flux-Cored Arc Welding.

- DNV GL Rules for Classification of Ships - Ch.4 Part 2: Welding.

- Lincoln Electric - The Procedure Handbook of Arc Welding, 15th Edition.

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025