Mar . 04, 2025 11:48

Back to list

Metal Spool K300 Welding Wire

The Comprehensive Guide to Choosing the Best ER70S-6 MIG Wire for Your Needs

A user-centric consideration is the quality of the wire's copper coating. It serves as a protective layer to prevent oxidation, thereby ensuring the longevity and stability of the welding current. When choosing a wire sourced from China, assessing the consistency and evenness of this coating is paramount. Chinese MIG wire manufacturers, particularly those with ISO certifications, adhere to rigorous quality control measures that assure consumers of optimal copper coating that facilitates smooth feeding through welding machines, leading to a stable arc and minimal spatter — critical aspects for clean, high-quality welds. Establishing an authoritative selection among Chinese-produced MIG wires requires examining the supplier’s credentials and reputation. Testimonials and case studies showcasing successful deployments in varied environments can greatly influence trust and decision-making. Engaging with China's top-tier manufacturers often provides advantages, including innovative manufacturing techniques and customized wire formulations that cater to specific industrial needs. Moreover, ensuring trustworthiness in your chosen MIG wire can be bolstered through certifications and standards adherence. Ensuring the wire meets international standards like the AWS A5.18/A5.18M is essential. Renowned Chinese suppliers consistently provide documentation and compliance guarantees that align with global quality expectations, further validated by third-party inspections and product audits that reinforce buyer confidence. Lastly, real-world experience with ER70S-6 wire profoundly enhances its usability value. Continuous feedback loops from end-users and industry professionals often lead to incremental product improvements. Many Chinese manufacturers have established robust feedback mechanisms where cumulative buyer insights shape subsequent production runs, ensuring that each batch meets evolving field requirements and exceeds performance expectations. In conclusion, selecting the best ER70S-6 MIG wire hinges on understanding your welding needs and the quality induced by the manufacturing origin. Chinese manufacturers, with their advanced production capabilities, offer substantial diversity and quality in their MIG wire selections. Rooted in rich industry experience, they stand well-equipped to supply welding setups that demand precision, efficiency, and longevity. Therefore, engaging in thorough research and critical evaluation of suppliers, while staying abreast of industry norms, can empower you to make an informed decision, securing the integrity and success of your welding projects.

A user-centric consideration is the quality of the wire's copper coating. It serves as a protective layer to prevent oxidation, thereby ensuring the longevity and stability of the welding current. When choosing a wire sourced from China, assessing the consistency and evenness of this coating is paramount. Chinese MIG wire manufacturers, particularly those with ISO certifications, adhere to rigorous quality control measures that assure consumers of optimal copper coating that facilitates smooth feeding through welding machines, leading to a stable arc and minimal spatter — critical aspects for clean, high-quality welds. Establishing an authoritative selection among Chinese-produced MIG wires requires examining the supplier’s credentials and reputation. Testimonials and case studies showcasing successful deployments in varied environments can greatly influence trust and decision-making. Engaging with China's top-tier manufacturers often provides advantages, including innovative manufacturing techniques and customized wire formulations that cater to specific industrial needs. Moreover, ensuring trustworthiness in your chosen MIG wire can be bolstered through certifications and standards adherence. Ensuring the wire meets international standards like the AWS A5.18/A5.18M is essential. Renowned Chinese suppliers consistently provide documentation and compliance guarantees that align with global quality expectations, further validated by third-party inspections and product audits that reinforce buyer confidence. Lastly, real-world experience with ER70S-6 wire profoundly enhances its usability value. Continuous feedback loops from end-users and industry professionals often lead to incremental product improvements. Many Chinese manufacturers have established robust feedback mechanisms where cumulative buyer insights shape subsequent production runs, ensuring that each batch meets evolving field requirements and exceeds performance expectations. In conclusion, selecting the best ER70S-6 MIG wire hinges on understanding your welding needs and the quality induced by the manufacturing origin. Chinese manufacturers, with their advanced production capabilities, offer substantial diversity and quality in their MIG wire selections. Rooted in rich industry experience, they stand well-equipped to supply welding setups that demand precision, efficiency, and longevity. Therefore, engaging in thorough research and critical evaluation of suppliers, while staying abreast of industry norms, can empower you to make an informed decision, securing the integrity and success of your welding projects.

Latest news

-

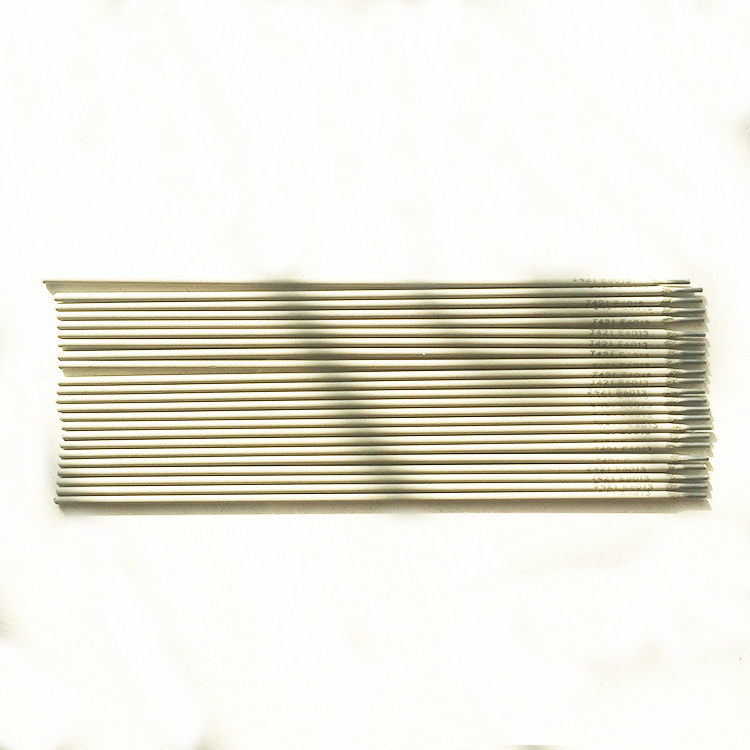

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025