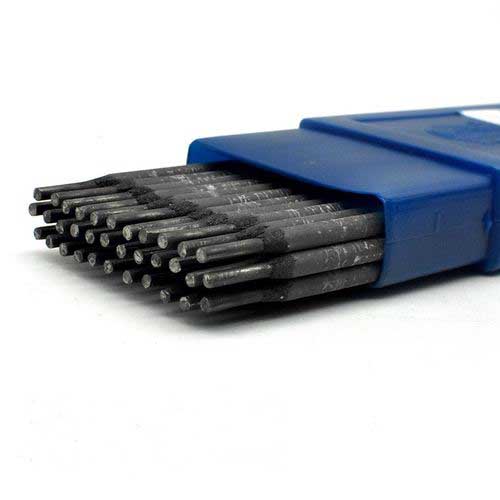

Factory supply Cast Iron Welding Rods AWS ENi-CI—Why Buy?

Field Notes on Cast Iron Repairs with Factory supply Cast Iron Welding Rods AWS ENi-CI

If you’ve spent late nights coaxing a cracked gearbox or a stubborn pump housing back to life, you know cast iron has its moods. These rods—marketed under THZ308—use a pure nickel core with a graphite-type coating. In practice, that means soft, machinable deposits and a surprising resistance to hot and cold cracking. AC or DC? Either is fine. In fact, the operator feedback I keep hearing is “no drama starts” and “no preheat needed in most jobs,” which, to be honest, saves time and coffee.

What’s under the coating

The core wire is high-purity Ni—great for matching thermal expansion and keeping the HAZ calm on gray and nodular cast irons. The flux is tuned for graphitic stabilization; slag peels are usually clean. I guess that’s why many customers say it “feels forgiving,” even when joint fit-up isn’t perfect.

Quick spec snapshot

| Parameter | Typical (≈) |

|---|---|

| AWS/ASME Classification | A5.15 ENi-CI |

| Diameters | 2.5 / 3.2 / 4.0 mm (others on request) |

| Lengths | 300–350 mm |

| Polarity | AC or DC+ (DCEP) |

| Weld Metal Tensile Strength | ≈ 380–450 MPa |

| Elongation | ≈ 18–25% |

| Hardness (as-welded) | ≈ 140–190 HB |

| Deposition Efficiency | ≈ 90% |

| Shelf Life (sealed) | 12 months; keep dry |

Process flow and QA

- Materials: pure nickel core wire; graphite-rich flux; low-hydrogen binders.

- Methods: precision extrusion; controlled baking (≈ 200–320°C); moisture control ≤ 0.4% (real-world may vary).

- Testing: OES chemistry check, coating weight and concentricity, diffusible hydrogen, bend tests, deposit tensile to AWS A5.15.

- Certifications: ISO 9001:2015 QMS; third‑party reports (e.g., SGS) available on request.

Where it shines

Repair welding gray iron engine blocks, gearboxes, machine tool beds, compressor and pump housings, agricultural castings, even ornate architectural iron. Usually no preheat; on massive or highly restrained sections, a gentle 80–120°C warm-up and peening between beads helps. Service life? In maintenance logs I’ve seen, repaired housings run 3–5 years before any rework—sometimes longer.

Customization

- Custom diameters/lengths, private labeling, moisture-resistant packaging.

- Procedure support: WPS drafts aligned with AWS D11.2 for cast iron practices.

- Origin: NO.368 YOUYI NORTH STREET, XINHUA DISTRICT, SHIJIAZHUANG CITY, CHINA.

Vendor landscape (what buyers compare)

| Vendor | Lead Time (≈) | MOQ | Customization | Cert/Test |

|---|---|---|---|---|

| Factory direct (this product) | 10–20 days | ≈ 500–1000 kg | Brand/size/pack | ISO 9001; AWS A5.15 test reports |

| Regional trading house | 20–35 days | Flexible | Limited | Varies by source |

| Generic market brand | Stock-dependent | Box-level | None | Basic COA |

In the field: two quick cases

Factory supply Cast Iron Welding Rods AWS ENi-CI in a Southeast Asia machine shop: cracked lathe bed (gray cast iron) restored with DC+, short beads, light peening; hardness averaged ≈ 165 HB; machining after 24 hours was smooth. Another: Midwest foundry repair on pump housings—no preheat, staged stops, interpass ≤ 120°C; repairs held through a full season with zero leak-backs, according to maintenance logs.

Why shops pick it

- Crack resistance and machinability—saves rework.

- AC/DC flexibility—runs on whatever the floor has.

- Good bead appearance—clean slag, tidy toes.

Customer feedback is mostly about predictability: “less porosity drama” and “post-weld tapping feels like steel.” That last one made me smile.

Standards, safety, and notes

- Classified under AWS A5.15 ENi-CI; follow WPS and shop ventilation best practices.

- Dry rods before use if packaging was open (≈ 120–150°C for 1 hour).

- For highly restrained joints, stitch technique, hammer peening, and slow cool in dry sand help.

References

- AWS A5.15/A5.15M: Specification for Welding Electrodes and Rods for Cast Iron.

- AWS D11.2: Guide for Welding Iron Castings.

- ASM Handbook, Vol. 6: Welding, Brazing, and Soldering, ASM International.

- ISO 9001:2015 Quality Management Systems – Requirements.

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025