Rutile Welding Rods: Easy Start, Low Spatter—Best Value?

What welders really mean when they ask for rutile welding rods

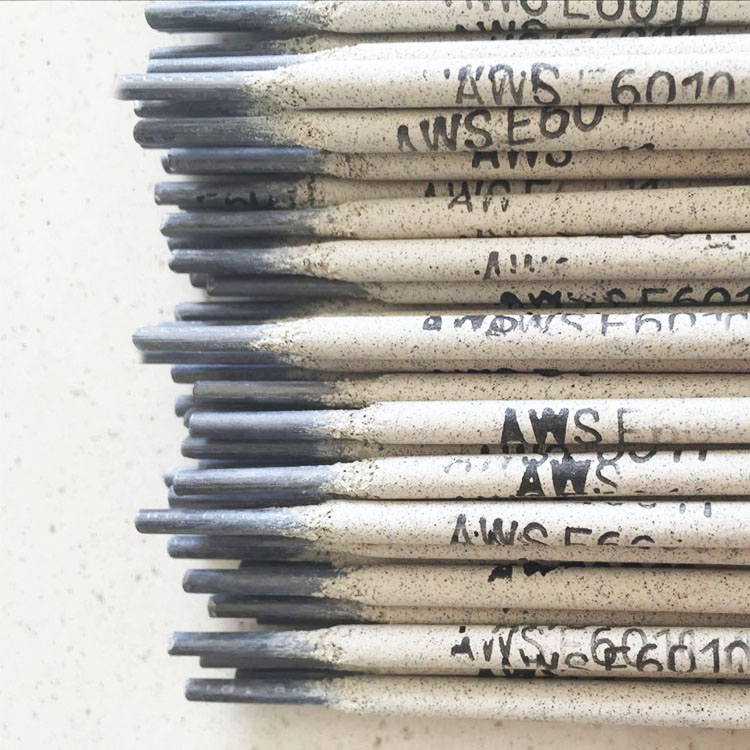

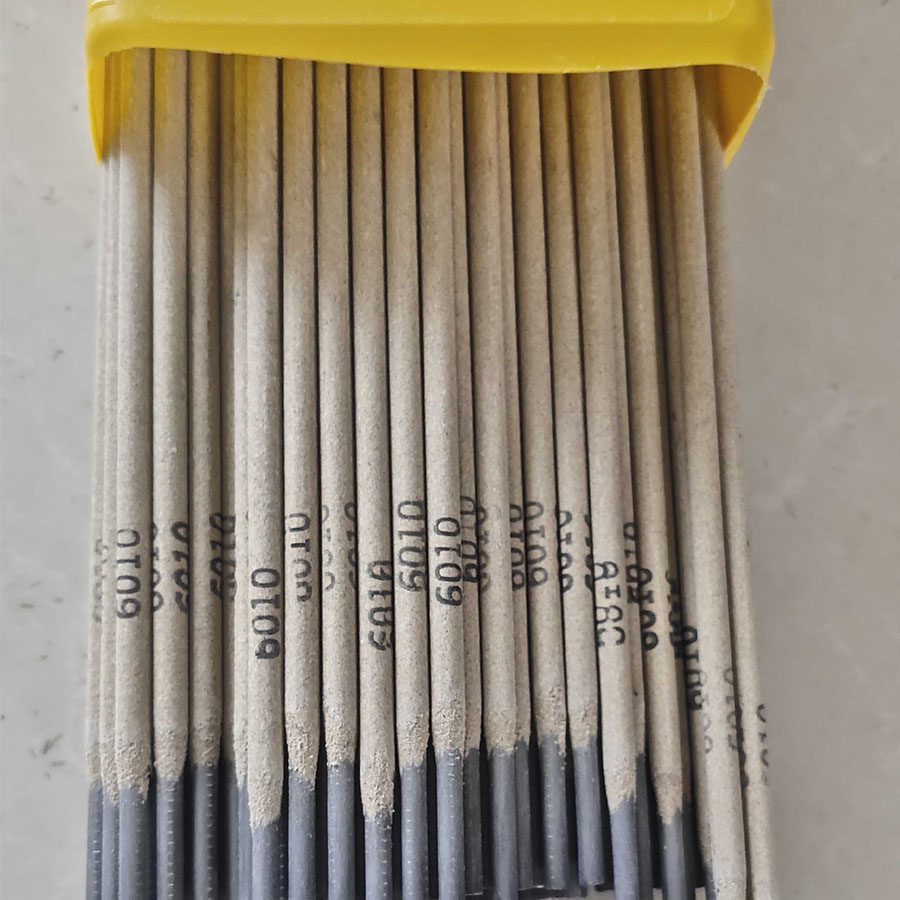

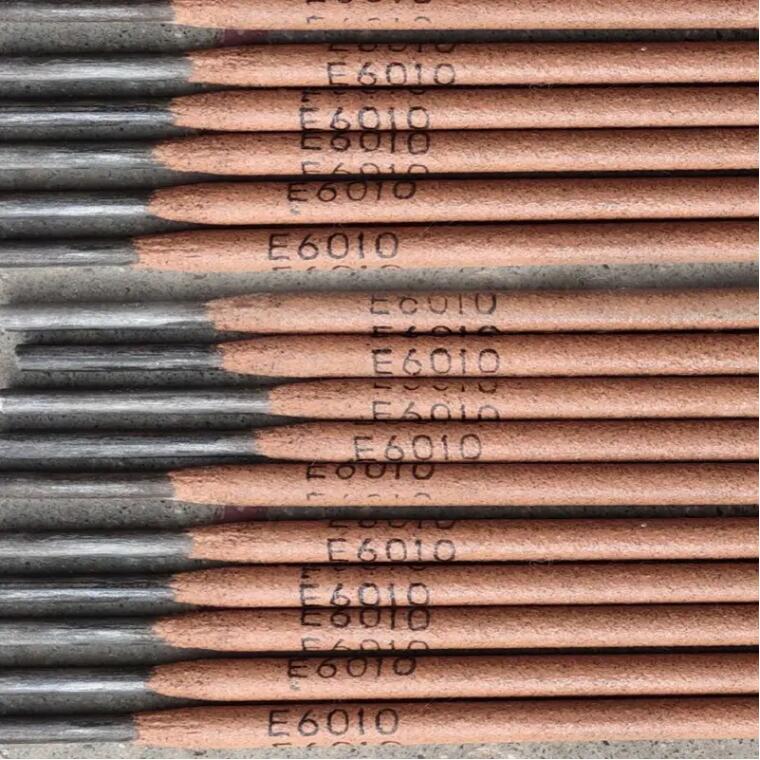

Shop floors and site crews use shorthand. Someone calls for rutile welding rods and, a minute later, another tech says, “No, we need 6010s for the root.” It happens all the time. To be honest, both are staples: rutile-coated rods (often E6013/E7014) for smooth, low-splatter fillets and sheet work; cellulose-coated E6010 for fast-freeze roots, especially pipelines. The product linked here—AWS E6010 Welding Electrodes Sticks (PM PRO-60)—is pipeline-focused, not rutile, yet many buyers cross-check them side by side before purchasing.

Where the market is heading

Industry trend-wise, I see three currents: (1) a steady shift toward low-hydrogen consumables for critical joints, (2) QR-coded batch traceability (surprisingly useful on shutdowns), and (3) hybrid procedures—E6010 for the root, rutile welding rods (E6013/7014) for fills and caps on mild steel where code allows. Many customers say this mix balances arc control and productivity.

Product snapshot: AWS E6010 Welding Electrodes Sticks (PM PRO-60)

Origin: NO.368 YOUYI NORTH STREET, XINHUA DISTRICT, SHIJIAZHUANG CITY, CHINA. Designed for pipeline work—open-root, all-position. Not rutile, but often paired with rutile welding rods for later passes in non-sour service.

| Parameter | Spec (≈, real-world may vary) |

|---|---|

| Classification | AWS A5.1 E6010 |

| Typical Tensile Strength | ≥ 60 ksi (≈ 410 MPa) |

| Positions | All positions, excels in vertical-up & open-root |

| Current | DCEP (stick+) |

| Typical Diameter Range | 2.5–4.0 mm |

| Diffusible Hydrogen | Higher vs. rutile/low-H; adhere to WPS and preheat rules |

Quality/testing: AWS A5.1 lot testing, bend tests per ASME Section IX, and procedure qualification to API 1104 for pipeline jobs. In our field notes, sound roots with good keyhole control were achieved with short arc length and whip/pause technique.

Rutile vs. E6010 at a glance

- rutile welding rods (e.g., E6013): smooth arc, easy slag removal, attractive beads on thin to medium sections; AC/DC friendly.

- E6010 (cellulose): deep penetration, fast freeze, ideal for open-root pipe and positional work.

- Common real-world workflow: E6010 root + rutile welding rods or E7018 for fill/cap (project and code dependent).

Vendor comparison (selection)

| Vendor | Focus/Coating | Certs | Lead Time | Notes |

|---|---|---|---|---|

| Steel Tools China (PM PRO-60) | E6010 (pipeline) | AWS A5.1, API 1104 support | ≈ 2–4 weeks | Strong open-root control; can pair with rutile welding rods. |

| ESAB (OK series) | Rutile E6013/E7014 | EN ISO 2560-A | ≈ 1–3 weeks | Clean bead appearance; easy AC starts. |

| Lincoln Electric (Fleetweld) | Rutile E6013 | AWS/CSA | Stock dependent | Good for light fabrication and training. |

Applications, process, and service life

Industries: pipeline construction, repair, structural steel, shipyards. Process flow (typical pipeline joint): fit-up and tacking → E6010 open-root pass (DCEP, whip/pause) → hot pass → fill/cap with rutile welding rods or low-hydrogen depending on WPS → visual (VT), bend/RT/UT to code → coating/commissioning. Service life: controlled by procedure quality, environment, and post-weld coating; in benign service, well-executed welds routinely match base-metal life.

Case notes and customization

Quick case: a North China gas spur line needed rapid tie-ins during a 10-hour outage. The crew ran E6010 roots for control on slightly misaligned joints, then switched to rutile welding rods for a clean cap where inspectors prioritized appearance. Welds passed radiography first shot, which—believe me—is everyone’s favorite outcome. Customization options include diameter mix, packaging with moisture indicators, and batch certificates tied to QR-coded pallets.

Customer feedback: “Keyhole stays stable; starts are predictable. We keep a few cartons of rutile sticks on the same pallet for cap passes—saves time.”

Standards and references

- AWS A5.1/A5.1M: Specification for Carbon Steel Electrodes for Shielded Metal Arc Welding.

- API 1104: Welding of Pipelines and Related Facilities.

- ASME Section IX: Welding, Brazing, and Fusing Qualifications.

- EN ISO 2560-A: Covered electrodes for manual metal arc welding of non-alloy and fine grain steels.

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025