AWS E6010 Welding Rods - Deep Penetration, Pipe Welding

aws e6010 welding rods, aws a5 1 e6010, aws e6010 electrode is a key solution in the manufacturing industry, specifically within Fabricated metal products and Welding material manufacturing. This article explores how HEBEI YUJINHONG TECHNOLOGY CO.,LTD. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- aws e6010 welding rods, aws a5 1 e6010, aws e6010 electrode Overview

- Benefits & Use Cases of aws e6010 welding rods, aws a5 1 e6010, aws e6010 electrode in Welding material manufacturing

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on aws e6010 welding rods, aws a5 1 e6010, aws e6010 electrode from HEBEI YUJINHONG TECHNOLOGY CO.,LTD.

aws e6010 welding rods, aws a5 1 e6010, aws e6010 electrode Overview

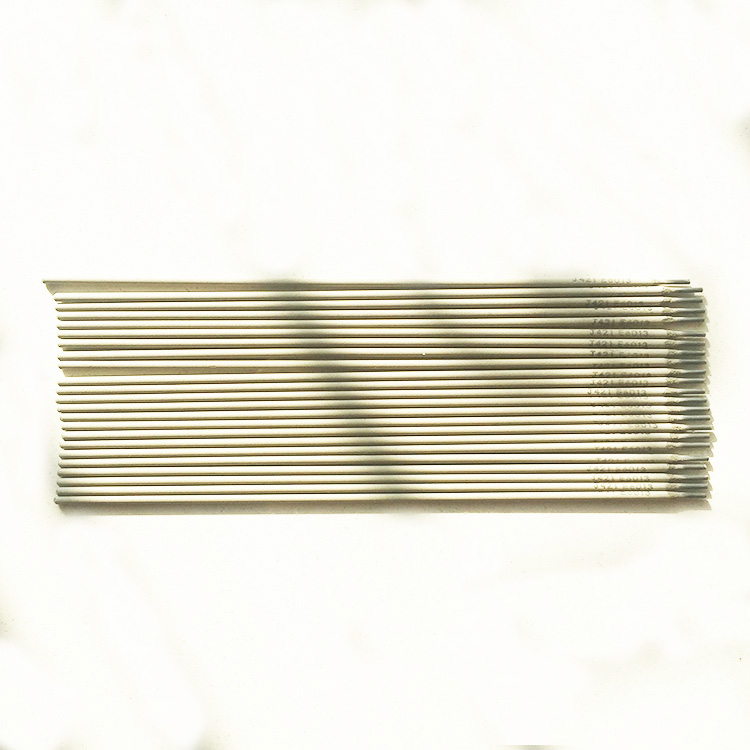

The aws e6010 electrode is a cellulosic-sodium coated, all-position stick electrode optimized for DC+ (DCEP) welding. Classified under AWS A5.1 E6010, it delivers deep penetration and a fast-freezing slag, making it the go-to choice for open-root passes on carbon steel pipe and for out-of-position work where productivity and arc control matter. Typical mechanical properties include 60 ksi (min) tensile strength and excellent root fusion on less-than-ideal fit-ups. Common diameters (2.5/3.2/4.0 mm) support amperage ranges suitable for field and shop work, while the arc’s aggressive digging action helps burn through light rust, mill scale, and coatings.

HEBEI YUJINHONG TECHNOLOGY CO.,LTD. manufactures aws e6010 welding rods to stringent quality standards for repeatable performance. With stable arc force, consistent moisture content in the coating, and batch-to-batch traceability, the company’s aws a5 1 e6010 offering helps fabricators, pipefitters, and contractors maintain code-quality roots and sound tie-ins. For full specifications and ordering options, visit the product page above.

Benefits & Use Cases of aws e6010 welding rods, aws a5 1 e6010, aws e6010 electrode in Welding material manufacturing

In Welding material manufacturing and fabricated metal production, the aws e6010 welding rods shine where reliability and speed intersect. Their fast-freeze slag supports vertical-up and vertical-down techniques, enabling quick, clean open-root passes on pipelines, process piping, water mains, and structural connections. The strong, focused arc of an aws e6010 electrode reduces undercut and improves sidewall fusion, while its deep penetration allows fewer passes and less joint preparation on many carbon steel applications.

Typical use cases include pipeline root and hot passes, tie-ins, and repair welding in the field—especially where wind, humidity, or surface contamination would challenge other electrodes. Competitive advantages include: robust arc starts, engineered moisture content for consistent performance, and excellent puddle control when whipping or stepping. HEBEI YUJINHONG TECHNOLOGY CO.,LTD. backs these benefits with disciplined quality management and application support, helping B2B teams specify the right size and current ranges to meet procedure qualification requirements without compromising productivity or weld integrity.

Cost, Maintenance & User Experience

For B2B decision makers, total cost of ownership centers on throughput, rework rates, and consumable stability. aws e6010 welding rods enable fast root passes and strong fusion, which can lower grinding and repair time—key drivers of ROI in pipe spools, utility lines, and field maintenance. Customers in the fabricated metal products sector report consistent puddle behavior and fewer restarts when paired with stable DC welding sources, translating to predictable labor hours and improved schedule certainty.

Maintenance is straightforward: keep aws a5 1 e6010 electrodes in sealed packaging until use and store in a cool, dry area. Unlike low-hydrogen rods, cellulosic aws e6010 electrode types are not typically oven-baked; avoid high-temperature rebaking that can degrade the coating. With correct storage and procedure adherence, operators benefit from minimized arc outages, clean bead profiles, and reduced post-weld cleanup—ultimately improving productivity and lowering per-joint costs.

Sustainability & Market Trends in manufacturing

Manufacturers are aligning welding consumables with broader sustainability goals—achieving more with fewer passes, less grinding, and less scrap. The fast-freezing behavior of aws e6010 welding rods supports efficient open-root techniques that can reduce rework and associated energy use. As infrastructure renewal accelerates—pipelines, municipal water systems, and industrial utilities—demand for reliable E6010-class electrodes is rising, especially in geographies emphasizing resilience and lifecycle cost control.

HEBEI YUJINHONG TECHNOLOGY CO.,LTD. integrates quality assurance and responsible sourcing to deliver consistent aws e6010 electrode performance while supporting waste minimization via optimized packaging and batch traceability. Compliance with AWS A5.1 standards ensures code-ready consumables for qualified procedures, while the company’s process improvements and technical guidance help fabricators meet tightening project timelines, EHS expectations, and audit requirements—without sacrificing weld soundness or operator efficiency.

Conclusion on aws e6010 welding rods, aws a5 1 e6010, aws e6010 electrode from HEBEI YUJINHONG TECHNOLOGY CO.,LTD.

For pipeline roots, field fabrication, and demanding out-of-position work, aws e6010 welding rods provide the deep penetration and control that B2B manufacturers require. HEBEI YUJINHONG TECHNOLOGY CO.,LTD. delivers AWS A5.1 E6010 electrodes engineered for consistency, productivity, and code compliance—helping teams cut rework, stabilize schedules, and protect margins.

Contact us: email: info@steeltoolschina.com

Visit our website: https://www.steeltoolschina.com

-

What is a medium-frequency pulse? What types of welding are suitable for?NewsNov.24,2025

-

Why is the overall cost of CO2 welding lower than that of shielded metal arc welding?NewsNov.21,2025

-

Welding Knowledge 6NewsNov.20,2025

-

What is a low-frequency pulse? What types of welding are they suitable for?NewsNov.19,2025

-

Why are the weld joints from CO₂ gas shielded welding of such high quality?NewsNov.18,2025

-

J506 Welding Rod - Low Hydrogen, All-Position, AC/DC E7016NewsNov.17,2025