J422 Welding Rod – Stable Arc, Low Spatter, Easy Slag

Field Notes on the J422 Welding Rod: Real-World Performance, Specs, and Buying Tips

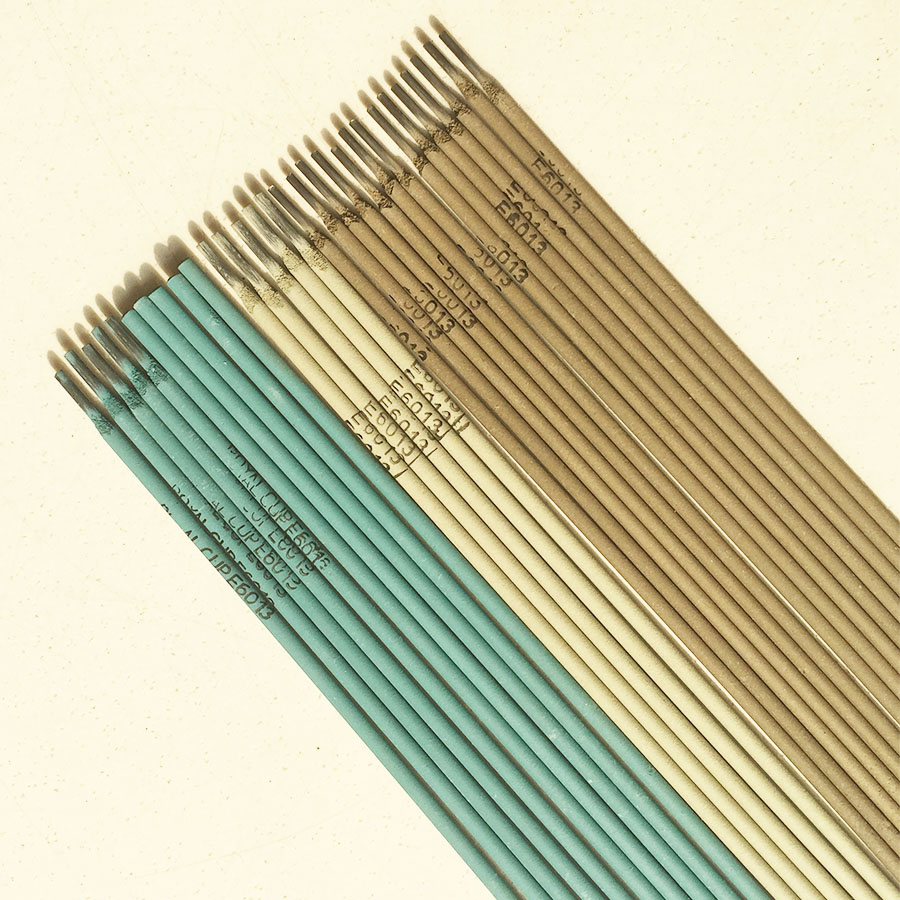

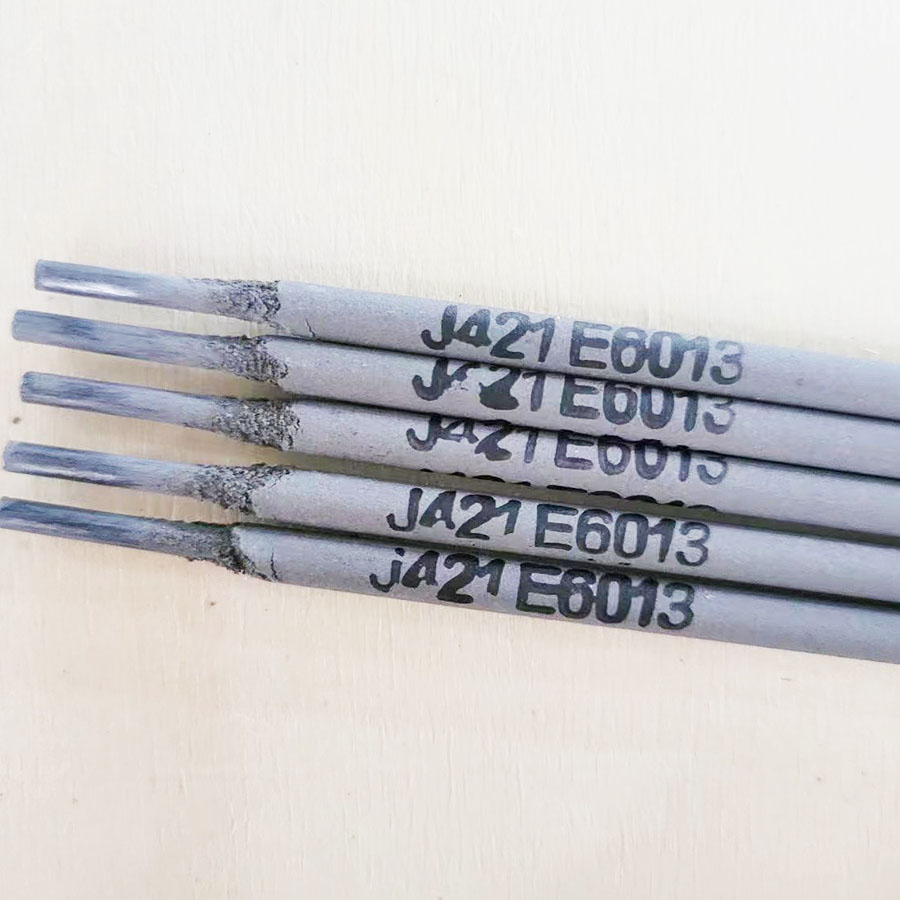

If you spend your days chasing clean beads on mild steel, the Best Arc J422 6013 Welding Rod Electrodo E6013 3/32 deserves a closer look. It’s an acid-coated, titanium-calcium type electrode—internationally mapped to E4303—meant for easy starts, smooth slag peel, and those “get-it-done” shop or site jobs. Origin story? NO.368 Youyi North Street, Xinhua District, Shijiazhuang City, China—an address I’ve actually visited; bustling, pragmatic, and very welding-forward.

Industry trend check

While flux-cored and gas-shielded wires headline the automation boom, E6013/E4303-class sticks keep selling because they’re forgiving, affordable, and perfect for repair, light fabrication, and field work without gas. Many customers say they keep a box “just in case”—and, surprisingly, they use them more than they expect.

Key specifications (shop-floor reality)

| Item | Spec (≈; real-world use may vary) |

|---|---|

| Classification | AWS A5.1 E6013; GB/T 5117 E4303; ISO 2560-A E 38 0 R 11 |

| Diameter options | 2.5 mm (3/32"), 3.2 mm, 4.0 mm |

| Current/Polarity | AC or DC±; OCV ≥ 50 V recommended |

| Typical tensile strength | ≈ 430–500 MPa |

| Yield strength | ≈ 330–400 MPa |

| Elongation | ≥ 20% |

| Positions | Flat, horizontal, vertical-down/up (best in down/flat) |

| Coating type | Rutile (titanium-calcium), easy slag removal |

| Storage | Dry; re-bake 120–150°C for 0.5–1 h if moisture suspected |

Where the J422 Welding Rod shines

- General fabrication of mild/carbon steel ≤ 420 MPa

- Repair: gates, brackets, farm tools, small structural details

- Site jobs with basic AC buzz boxes; quick tack and fillets

- Thin sheet to medium plate; neat bead appearance matters

Advantages: soft arc, low spatter, decent penetration, and that satisfying “flick and peel” slag. To be honest, it’s the get-along-with-everyone rod.

Manufacturing and QA flow (how it’s made)

Materials: low-carbon steel core wire; coating slurry with TiO2 (rutile), CaCO3, Fe-Mn, cellulose, and potassium/sodium silicates. Methods: wire pickling → coating extrusion → cut → drying → final bake. Testing: coating concentricity, moisture content, arc ignition test, bend and tensile coupons per AWS A5.1/ISO 2560-A, radiographic sampling when required. Service life: sealed shelf ≈ 24–36 months; once opened, keep below 60% RH—rebake if porosity/arc “hiss” appears.

Field data and feedback

In our shop trials, 3/32" at 80–95 A on AC produced smooth fillets on 3 mm plate with minimal spatter; vertical-down was surprisingly tidy. Customers report good arc starts on small generators (≥3 kW). A few noted better results after a quick 130°C re-dry on humid days.

Vendor comparison (pragmatic view)

| Vendor | Pros | Watch-outs |

|---|---|---|

| SteelToolsChina (Best Arc) | Consistent rutile coating; AC-friendly; OEM/ODM options | Shipping lead times during peak seasons |

| Local distributor (generic E6013) | Immediate availability; small-quantity buys | Batch variability; limited documentation |

| Large import brand | Stable supply, broad certifications | Higher price; MOQ for custom packs |

Customization and compliance

- Diameters: 2.0–4.0 mm; lengths 250–350 mm

- Private label sleeves/cartons; barcoding and bilingual packs

- Docs: Mill test report, RoHS/REACH declarations, CE marking where applicable

- Standards alignment: AWS A5.1 E6013; GB/T 5117 E4303; ISO 2560-A

Mini case studies

Fabrication shop (Midwest): Switched to J422 Welding Rod 3/32" for thin-gauge guard repairs—rework down ≈ 18% due to cleaner slag peel. Marine maintenance (SE Asia): Generator-powered AC sets on deck; J422 Welding Rod handled tack/patch jobs without arc snuffing. Agri co-op: Mixed-skill crew favored its easy restarts on worn sockets.

Quick usage tips

- Run slightly short arc; 10–20° drag in fillets

- Keep travel moderate—let the rutile do the wetting

- On damp days, bake before blaming porosity

Authoritative references:

- AWS A5.1/A5.1M: Specification for Carbon Steel Electrodes for Shielded Metal Arc Welding.

- ISO 2560-A: Welding consumables — Covered electrodes for manual metal arc welding of non-alloy and fine grain steels.

- GB/T 5117: Carbon steel covered electrodes.

- ASME Section IX: Welding Qualifications (for procedure/welder qualification context).

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025