CO2 Gas Shielded Copper Plated Micro Wire-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.2513

Welding technology has evolved significantly to meet the demands of modern industrial applications. Among the innovations, CO2 gas shielded copper-plated micro wire stands out as a critical solution for high-efficiency, corrosion-resistant, and durable welding processes. This article delves into the features, technical specifications, applications, and company background of this advanced welding material, providing a detailed overview for professionals and industry stakeholders.

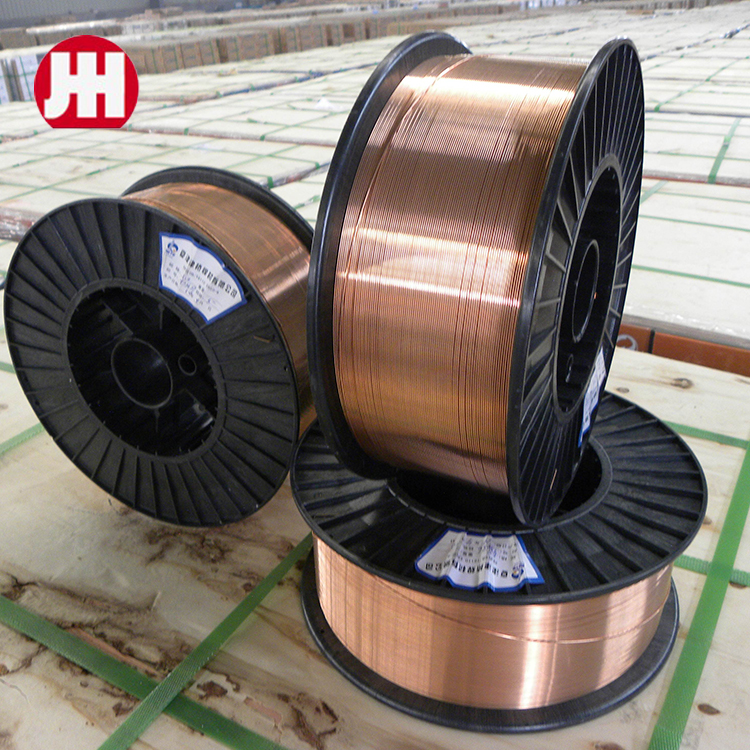

Product Overview

The CO2 gas shielded copper-plated micro wire is a specialized welding consumable designed for carbon steel welding. It is particularly effective in CO2 or 80% Ar + 20% CO2 gas shielded arc welding, offering a combination of high performance and cost-efficiency. This wire is engineered to minimize spatter, ensure a beautiful weld appearance, and deliver high cladding efficiency. Its low sensitivity to weld metal porosity and excellent all-position welding capabilities make it a preferred choice across various industries.

Key Features and Advantages

The CO2 gas shielded copper-plated micro wire is designed to address common challenges in welding, such as corrosion, spatter, and poor weld quality. Here are its standout features:

- Low Spatter and High Cladding Efficiency: The wire ensures minimal spatter during welding, resulting in a clean and aesthetically pleasing weld surface. This reduces post-welding cleanup and improves productivity.

- Excellent All-Position Welding Performance: Capable of welding in PA, PB, PC, PD, PE, PF positions, this wire adapts to complex and challenging welding scenarios, making it versatile for diverse applications.

- Corrosion Resistance: The copper plating on the wire's surface acts as a protective layer, preventing rust and corrosion. This extends the wire's shelf life and ensures consistent performance in humid or corrosive environments.

- Enhanced Electrical Conductivity: The smooth copper coating improves the wire's electrical conductivity, ensuring stable arc performance and reducing the risk of welding defects.

- Low Hydrogen and Nitrogen Content: The weld metal has minimal hydrogen and nitrogen, which significantly reduces the risk of cracks and improves the structural integrity of the weld.

Technical Specifications

| Parameter | Details |

|---|---|

| Material | Carbon Steel (ER70S-6) |

| Tensile Strength | 500 MPa |

| Shielding Gas | CO2 or 80% Ar + 20% CO2 |

| Coating | Copper Plating |

| Welding Positions | PA, PB, PC, PD, PE, PF |

| Spatter Level | Low |

| Porosity Sensitivity | Low |

| Corrosion Resistance | High |

Applications in Industry

The CO2 gas shielded copper-plated micro wire is widely used in manufacturing, construction, and automotive industries due to its adaptability and performance. Key applications include:

- Structural Steel Welding: Ideal for welding thin, medium, and thick plates in construction and heavy machinery, ensuring strong and durable joints.

- Automotive Manufacturing: The wire's low spatter and high efficiency make it suitable for car body assembly and frame welding, where precision and speed are critical.

- Industrial Fabrication: Used in pipeline construction, shipbuilding, and equipment manufacturing, where corrosion resistance and weld quality are paramount.

- Repair and Maintenance: Its all-position welding capability allows for on-site repairs in challenging environments, reducing downtime and maintenance costs.

Company Background: Hebei Yujinhong Technology Co., Ltd.

Hebei Yujinhong Technology Co., Ltd. (HEBEI YUJINHONG TECHNOLOGY CO.,LTD.) is a leading manufacturer of high-quality welding consumables. With a focus on advanced production technology and strict quality control, the company ensures that its products meet international standards. Their commitment to innovation and customer satisfaction has positioned them as a trusted partner in the welding industry.

For more information about the company, visit their product page or explore their official website.

Why Choose CO2 Gas Shielded Copper-Plated Micro Wire?

The CO2 gas shielded copper-plated micro wire offers a unique combination of cost-effectiveness, durability, and performance. Its low welding cost, high production efficiency, and easy operation make it a preferred choice for industries seeking to optimize their welding processes. Additionally, the wire's low deformation after welding and wide application range ensure its suitability for both small-scale and large-scale projects.

Industry Standards and Certifications

As a National Metrology Institute, the National Institute of Standards and Technology (NIST) plays a critical role in establishing standards for welding materials. While the specific CO2 gas shielded copper-plated micro wire may not be directly referenced in NIST's documentation, the organization's work in precision measurements and material science ensures that products like this meet rigorous quality benchmarks. For more details on NIST's contributions to welding standards, visit their official website.

According to NIST, "Precision measurements and standards are essential for ensuring the reliability and performance of materials used in critical industries such as aerospace, automotive, and construction" (NIST, 2025).

Conclusion

The CO2 gas shielded copper-plated micro wire represents a significant advancement in welding technology. With its corrosion resistance, low spatter, and all-position welding capabilities, it addresses the evolving needs of modern industries. Hebei Yujinhong Technology Co., Ltd. continues to innovate, delivering products that meet the highest standards of quality and performance.

For further details about this product, visit the CO2 Gas Shielded Copper Plated Micro Wire product page or contact the company directly through their official website.

References

National Institute of Standards and Technology (NIST) (2025). "Precision Measurements and Material Standards." Retrieved from https://www.nist.gov.

-

What is a medium-frequency pulse? What types of welding are suitable for?NewsNov.24,2025

-

Why is the overall cost of CO2 welding lower than that of shielded metal arc welding?NewsNov.21,2025

-

Welding Knowledge 6NewsNov.20,2025

-

What is a low-frequency pulse? What types of welding are they suitable for?NewsNov.19,2025

-

Why are the weld joints from CO₂ gas shielded welding of such high quality?NewsNov.18,2025

-

J506 Welding Rod - Low Hydrogen, All-Position, AC/DC E7016NewsNov.17,2025

CO2 Gas Shielded Copper Plated Micro Wire-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.2513

Welding technology has evolved significantly to meet the demands of modern industrial applications. Among the innovations, CO2 gas shielded copper-plated micro wire stands out as a critical solution for high-efficiency, corrosion-resistant, and durable welding processes. This article delves into the features, technical specifications, applications, and company background of this advanced welding material, providing a detailed overview for professionals and industry stakeholders.

Product Overview

The CO2 gas shielded copper-plated micro wire is a specialized welding consumable designed for carbon steel welding. It is particularly effective in CO2 or 80% Ar + 20% CO2 gas shielded arc welding, offering a combination of high performance and cost-efficiency. This wire is engineered to minimize spatter, ensure a beautiful weld appearance, and deliver high cladding efficiency. Its low sensitivity to weld metal porosity and excellent all-position welding capabilities make it a preferred choice across various industries.

Key Features and Advantages

The CO2 gas shielded copper-plated micro wire is designed to address common challenges in welding, such as corrosion, spatter, and poor weld quality. Here are its standout features:

- Low Spatter and High Cladding Efficiency: The wire ensures minimal spatter during welding, resulting in a clean and aesthetically pleasing weld surface. This reduces post-welding cleanup and improves productivity.

- Excellent All-Position Welding Performance: Capable of welding in PA, PB, PC, PD, PE, PF positions, this wire adapts to complex and challenging welding scenarios, making it versatile for diverse applications.

- Corrosion Resistance: The copper plating on the wire's surface acts as a protective layer, preventing rust and corrosion. This extends the wire's shelf life and ensures consistent performance in humid or corrosive environments.

- Enhanced Electrical Conductivity: The smooth copper coating improves the wire's electrical conductivity, ensuring stable arc performance and reducing the risk of welding defects.

- Low Hydrogen and Nitrogen Content: The weld metal has minimal hydrogen and nitrogen, which significantly reduces the risk of cracks and improves the structural integrity of the weld.

Technical Specifications

| Parameter | Details |

|---|---|

| Material | Carbon Steel (ER70S-6) |

| Tensile Strength | 500 MPa |

| Shielding Gas | CO2 or 80% Ar + 20% CO2 |

| Coating | Copper Plating |

| Welding Positions | PA, PB, PC, PD, PE, PF |

| Spatter Level | Low |

| Porosity Sensitivity | Low |

| Corrosion Resistance | High |

Applications in Industry

The CO2 gas shielded copper-plated micro wire is widely used in manufacturing, construction, and automotive industries due to its adaptability and performance. Key applications include:

- Structural Steel Welding: Ideal for welding thin, medium, and thick plates in construction and heavy machinery, ensuring strong and durable joints.

- Automotive Manufacturing: The wire's low spatter and high efficiency make it suitable for car body assembly and frame welding, where precision and speed are critical.

- Industrial Fabrication: Used in pipeline construction, shipbuilding, and equipment manufacturing, where corrosion resistance and weld quality are paramount.

- Repair and Maintenance: Its all-position welding capability allows for on-site repairs in challenging environments, reducing downtime and maintenance costs.

Company Background: Hebei Yujinhong Technology Co., Ltd.

Hebei Yujinhong Technology Co., Ltd. (HEBEI YUJINHONG TECHNOLOGY CO.,LTD.) is a leading manufacturer of high-quality welding consumables. With a focus on advanced production technology and strict quality control, the company ensures that its products meet international standards. Their commitment to innovation and customer satisfaction has positioned them as a trusted partner in the welding industry.

For more information about the company, visit their product page or explore their official website.

Why Choose CO2 Gas Shielded Copper-Plated Micro Wire?

The CO2 gas shielded copper-plated micro wire offers a unique combination of cost-effectiveness, durability, and performance. Its low welding cost, high production efficiency, and easy operation make it a preferred choice for industries seeking to optimize their welding processes. Additionally, the wire's low deformation after welding and wide application range ensure its suitability for both small-scale and large-scale projects.

Industry Standards and Certifications

As a National Metrology Institute, the National Institute of Standards and Technology (NIST) plays a critical role in establishing standards for welding materials. While the specific CO2 gas shielded copper-plated micro wire may not be directly referenced in NIST's documentation, the organization's work in precision measurements and material science ensures that products like this meet rigorous quality benchmarks. For more details on NIST's contributions to welding standards, visit their official website.

According to NIST, "Precision measurements and standards are essential for ensuring the reliability and performance of materials used in critical industries such as aerospace, automotive, and construction" (NIST, 2025).

Conclusion

The CO2 gas shielded copper-plated micro wire represents a significant advancement in welding technology. With its corrosion resistance, low spatter, and all-position welding capabilities, it addresses the evolving needs of modern industries. Hebei Yujinhong Technology Co., Ltd. continues to innovate, delivering products that meet the highest standards of quality and performance.

For further details about this product, visit the CO2 Gas Shielded Copper Plated Micro Wire product page or contact the company directly through their official website.

References

National Institute of Standards and Technology (NIST) (2025). "Precision Measurements and Material Standards." Retrieved from https://www.nist.gov.