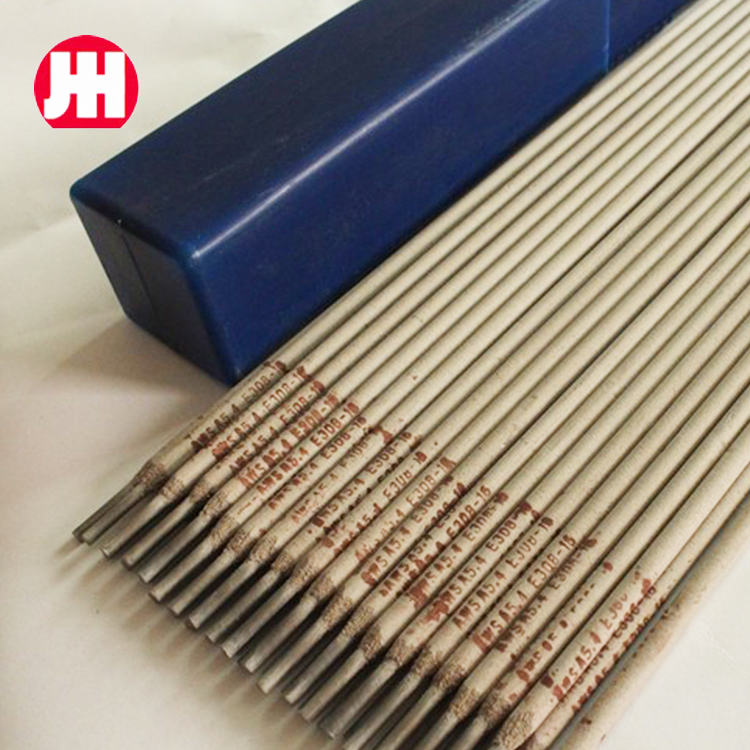

E309 Welding Electrode: Premium Stainless Steel Stick Rods

Unlocking Global Opportunities: Top Welding Rod & Welding Wire Manufacturers at the Canton Fair

Introduction: The Canton Fair – A Gateway to Industrial Excellence

For B2B decision-makers worldwide, the Canton Fair stands as an unparalleled nexus for global trade, a dynamic showcase of innovation, quality, and competitive manufacturing. Renowned for bringing together a vast array of high-quality steel tools and industrial hardware, this prestigious event offers an invaluable platform for businesses to discover cutting-edge solutions and forge strategic partnerships. In the critical realm of industrial consumables, particularly for the welding rod and welding wire industry, the Canton Fair is not merely an exhibition; it's a vital ecosystem for sourcing the latest advancements, networking with leading manufacturers, and ensuring the resilience and efficiency of your supply chain.

The demand for reliable, high-performance welding consumables is a constant across construction, manufacturing, shipbuilding, and energy sectors. As infrastructure projects scale globally and industrial processes become more complex, the need for superior welding rod and welding wire that deliver strength, durability, and consistent quality becomes paramount. Chinese manufacturers, in particular, have carved out a significant niche in this sector, leveraging their robust production capabilities, technological prowess, and cost-effectiveness to become indispensable partners for businesses seeking competitive advantage. This article delves into the trends, opportunities, and key players shaping the future of this essential industry, with a special focus on the insights gained from the Canton Fair.

Industry Trend Spotlight: Navigating the Evolving Landscape of Industrial Tools

The industrial tools sector, encompassing everything from hand tools to specialized welding consumables, is currently undergoing significant transformation, driven by a confluence of technological advancements and evolving market demands. Globally, there's an increasing emphasis on high-durability and ergonomically designed tools that enhance worker productivity and reduce fatigue. Furthermore, the integration of smart features for predictive maintenance and asset tracking is gaining traction, signaling a shift towards more intelligent industrial operations. Manufacturers are also increasingly leveraging advanced alloys to produce lighter yet stronger industrial tools, offering superior performance without compromising on structural integrity. A growing focus on precision and automation compatibility reflects the broader trend of industrial digitalization, where tools must seamlessly integrate into automated manufacturing lines.

Market data underscores this dynamic growth: the global industrial tools market is projected for steady expansion, fueled by renewed infrastructure spending worldwide, the vigorous expansion of the manufacturing sector, and increasing demand from rapidly developing economies. Digitalization and automation within manufacturing are powerful catalysts, driving the demand for highly specialized tools and consumables that can meet the stringent requirements of modern industrial processes. This includes advanced welding rod and welding wire formulations designed for robotic welding applications, high-tensile strength requirements, and specialized material joining.

Despite these opportunities, key considerations remain. Supply chain resilience has become a top priority in the wake of recent global disruptions, leading businesses to diversify their sourcing strategies. Raw material price volatility continues to be a challenge, prompting manufacturers to innovate in material usage and production efficiency. Emerging focus areas for B2B decision-makers include global sourcing for industrial tools, with a strong emphasis on supply chain diversification to mitigate risks. Quality assurance is paramount, especially for critical consumables like 309 stainless stick rods, where consistency directly impacts project integrity and safety. There's also a heightened interest in advanced material applications and the seamless integration of tools within smart manufacturing ecosystems, underscoring the shift towards more intelligent, efficient, and interconnected industrial environments.

Profiles of Leading Manufacturers: Innovation at the Core

HEBEI YUJINHONG TECHNOLOGY CO.,LTD.: A Beacon of Quality in Welding Consumables

Among the standout exhibitors at the Canton Fair and a pivotal player in the global industrial tools market, HEBEI YUJINHONG TECHNOLOGY CO.,LTD. distinguishes itself through its comprehensive specialization in a wide range of steel and hardware tools, with a particular emphasis on high-performance welding consumables. As a leading Chinese exporter, the company boasts strong manufacturing capabilities, leveraging advanced production lines and stringent quality control processes to deliver products that meet international standards. This commitment to efficiency and quality translates into competitive pricing, making them an attractive partner for global buyers.

HEBEI YUJINHONG TECHNOLOGY CO.,LTD. has successfully established a robust global distribution network, ensuring that their durable and high-performing products reach industrial applications across diverse markets. Their focus is unequivocally on product durability and performance, recognizing that in industrial environments, reliability is non-negotiable. For clients seeking specialized solutions, their extensive portfolio includes top-tier products like the e309 welding electrode and e309 welding rod. These are specifically engineered for welding dissimilar metals and stainless steels, offering excellent crack resistance and superior mechanical properties under demanding conditions. Their 309 stainless stick rods are particularly valued for their versatility and robust performance in critical applications requiring high integrity welds.

Discover the exceptional quality and performance of their products by visiting their dedicated product page: AWS E309-16 A302 Welding Electrodes for Stainless Steel.

Beyond: A Global Perspective

While Chinese manufacturers like HEBEI YUJINHONG TECHNOLOGY CO.,LTD. offer exceptional value and quality, the broader landscape of the industrial tools market also features established global giants. Companies such as Stanley Black & Decker, Bosch, and Makita continue to innovate across various tool categories, setting industry benchmarks for technology and user experience.

Furthermore, the Canton Fair often hosts a diverse range of specialized steel tool manufacturers and exporters from other prominent industrial hubs, including Taiwan and India. These regions contribute significantly to the global supply chain, offering niche products, advanced engineering, and alternative sourcing options. For B2B buyers, understanding this diverse ecosystem is crucial for building resilient, cost-effective, and high-quality supply networks. The synergy between these global and regional players fosters a competitive environment that ultimately benefits end-users through continuous innovation and improved product offerings in welding rod and welding wire technology.

Market Outlook & Opportunities: Charting the Future of Welding Consumables

The future of the welding rod and welding wire market is poised for significant evolution, driven by a blend of technological advancements and changing buyer demands. Upcoming trends indicate a surging demand for specialized alloys and high-performance consumables capable of withstanding extreme conditions and joining advanced materials. This includes a growing need for e309 welding electrode and similar specialized rods for critical applications in chemical processing, power generation, and high-temperature environments. Efficiency remains a key driver, pushing manufacturers to develop consumables that offer faster deposition rates, reduced spatter, and superior weld integrity, thereby lowering overall operational costs.

Buyer demand is increasingly focused on consistent quality, traceability, and certifications, particularly for products like 309 stainless stick rods used in high-stakes projects. Cost-effectiveness, without compromising on performance, remains a perennial concern, prompting greater scrutiny of total lifecycle costs rather than just upfront purchase prices.

Significant opportunities lie in the embrace of automation and smart manufacturing. Robotic welding systems are becoming more prevalent, creating a niche for welding wire and welding rod specifically optimized for automated processes, offering consistent feedability and arc stability. Smart manufacturing integration involves the use of IoT-enabled consumables and tracking systems that provide real-time data on usage, performance, and inventory, enhancing operational visibility and control. Furthermore, sustainability is emerging as a critical factor. Manufacturers adopting eco-friendly production methods, recyclable packaging, and developing consumables that reduce fumes or energy consumption will gain a competitive edge. These opportunities highlight a dynamic market where innovation, efficiency, and environmental responsibility will define success.

Buyer/Business Takeaways: Strategic Sourcing for the Future

For B2B decision-makers, understanding the strategic importance of investing in high-quality welding rod and welding wire cannot be overstated. These consumables are the bedrock of robust construction, manufacturing, and repair operations across virtually all industrial sectors. Their quality directly impacts the structural integrity, durability, and safety of finished products and infrastructure. Choosing the right e309 welding electrode or 309 stainless stick rods, for instance, ensures optimal performance in demanding environments, preventing costly failures and rework.

When considering partnerships with Chinese manufacturers, a strategic approach is key to maximizing benefits:

- Due Diligence: Thoroughly vet potential partners. Research their manufacturing capabilities, certifications (e.g., ISO, AWS), and track record. Factory visits, where possible, offer invaluable insights.

- Clear Communication: Establish precise specifications, quality standards, and delivery expectations upfront. Cultural nuances in communication should also be considered.

- Quality Control: Implement robust quality control measures, including third-party inspections, at various stages of production and pre-shipment. For critical products like welding wire, consistency is everything.

- Logistics & Export Processes: Understand the intricacies of international shipping, customs regulations, and Incoterms to avoid delays and unexpected costs.

- Build Relationships: Foster long-term relationships with trusted manufacturers. This can lead to better terms, preferential service, and collaborative innovation.

To future-proof your strategies in this evolving market, consider these actions:

- Diversify Your Supply Chain: Relying on a single source, even a highly reliable one, carries inherent risks. Explore multiple qualified suppliers.

- Invest in R&D: Stay abreast of new material science and welding technologies. Your partners should ideally be doing the same.

- Embrace New Technologies: Evaluate how smart tools and automation can be integrated into your operations, and ensure your consumables are compatible.

- Prioritize Sustainability: Align your procurement with environmentally responsible practices, as this will increasingly become a competitive differentiator.

Conclusion: The Canton Fair's Enduring Impact

The Canton Fair continues to play an indispensable role in shaping the global welding rod and welding wire market. It serves as a crucial platform where B2B decision-makers can connect with a vast network of manufacturers, explore the latest innovations, and secure high-quality, competitively priced industrial consumables. China's position as a manufacturing powerhouse, exemplified by companies like HEBEI YUJINHONG TECHNOLOGY CO.,LTD., remains undisputed, offering a compelling proposition for global buyers seeking reliability, advanced engineering, and robust supply chain solutions.

As the industrial landscape evolves, the demand for specialized, high-performance welding solutions like the e309 welding electrode and 309 stainless stick rods will only intensify. Strategic partnerships, informed sourcing, and an embrace of future-oriented technologies will be key to unlocking success in this vital sector.

To learn more about premium welding electrodes for stainless steel and other industrial tools, we invite you to visit:

Explore HEBEI YUJINHONG's E309 Welding Electrodes

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025