Factory supply Cast Iron Welding Rods AWS ENi-CI Machinable?

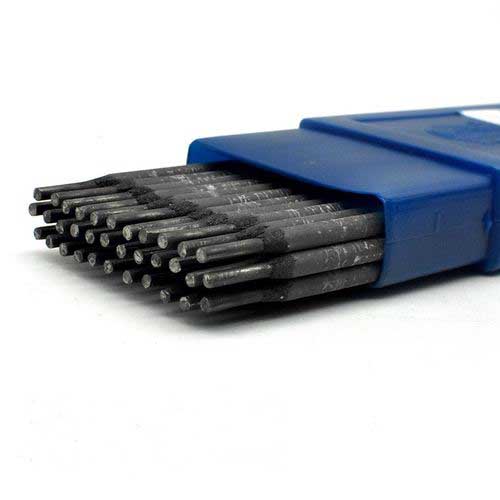

Factory supply Cast Iron Welding Rods AWS ENi-CI

If you’ve ever repaired a cracked lathe base or a finicky pump housing, you already know: cast iron has a personality. It wants a calm hand, a cool puddle, and the right consumable. That’s where Factory supply Cast Iron Welding Rods AWS ENi-CI (often nicknamed “ENi-CI cold-weld sticks”) come in. They’re built around a pure-nickel core with a graphite-type coating, AC/DC friendly, and—surprisingly—no preheat required in most cases. Many maintenance teams like the hassle-free start and the crack resistance. I do too, to be honest.

Why the market is leaning into ENi-CI now

Industry trend? Precision repairs without long downtime. Foundries, mines, and shipyards are pushing “cold” procedures to avoid distortion. In fact, nickel electrodes for cast iron have seen steady demand as older assets stay in service longer. Short beads, peening, and controlled interpass—paired with Factory supply Cast Iron Welding Rods AWS ENi-CI—is the real-world recipe.

Key Specifications (typical, real-world use may vary)

| Standard | AWS A5.15 ENi-CI |

| Core/Coating | Pure nickel core, graphite-type coating |

| Diameter × Length | 2.5×300 mm, 3.2×350 mm, 4.0×350 mm |

| Current/Polarity | AC or DC+, easy strike |

| Recommended Amps | 2.5 mm: 50–80 A; 3.2 mm: 70–110 A; 4.0 mm: 90–140 A |

| Tensile Strength | ≈ 400 MPa |

| Elongation | ≈ 18% |

| Hardness | ≈ 160–200 HB |

| Preheat | Not necessary for many jobs; use cold technique |

Where they’re used

- Repairing cracked engine blocks, gear housings, machine beds, and lathe pedestals

- Rebuilding worn pump casings and bearing seats

- Stitching repairs on gray, malleable, and some nodular cast irons (procedure-dependent)

Process flow and QA

Materials: pure nickel wire, controlled graphite coating. Methods: wire drawing, precision extrusion, low-hydrogen baking, batch traceability. Testing: per AWS A5.15—tensile, bend (where applicable), deposit chemistry checks; batch moisture control. Typical service life: multi-year repairs under normal loading; obviously, technique matters.

Field notes (real shops say)

“Easy start, low spatter, less post-weld grinding.” Another buyer mentioned fewer cold cracks when using short 20–30 mm beads with peening between passes. I guess the lesson is: procedure plus consumable equals success.

Vendor comparison (indicative)

| Criteria | This Factory (ENi-CI) | Vendor A | Vendor B |

|---|---|---|---|

| Certifications | ISO 9001:2015; AWS A5.15 compliant | ISO 9001 only | Claimed AWS |

| MOQ | ≈ 200–500 kg | 1 ton | 500 kg |

| Lead Time | 10–15 days | 3–4 weeks | 2–3 weeks |

| Customization | Diameters, packaging, private label | Limited | Standard only |

| After-sales | Procedure guidance available | Email only | Basic |

Case study: quarry crusher base

A quarry maintenance crew repaired a cracked gray-iron crusher base using 3.2 mm Factory supply Cast Iron Welding Rods AWS ENi-CI. Cold technique, 25 mm beads, peened each run. Post-weld dye penetrant showed no indications; unit returned to service in 24 hours. Six months later, still holding—no vibration-related cracking reported.

Practical tips

- Bevel lightly; keep heat input low. Pause between beads to cool to hand-warm.

- Peen gently to relieve stress. Grind smooth; avoid quenching.

- Store rods dry; re-bake around 110–150°C if moisture is suspected.

Origin and logistics

Origin: NO.368 YOUYI NORTH STREET, XINHUA DISTRICT, SHIJIAZHUANG CITY, CHINA. Packaging can be branded; batch certificates included. Honestly, the paperwork is tidy—helps with audits.

Certifications and references

- AWS A5.15 compliant testing (tensile, deposit checks)

- ISO 9001:2015 quality management

- WPS/PQR support in line with EN ISO 15614-1 (where required)

Authoritative citations

- AWS A5.15: Specification for Welding Electrodes and Rods for Cast Iron.

- ASM Handbook, Volume 6: Welding, Brazing, and Soldering.

- ISO 9001:2015 Quality Management Systems—Requirements.

- EN ISO 15614-1: Specification and qualification of welding procedures for metallic materials.

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025