Premium Flux Core MIG Wire Manufacturer | High-Quality Welding Solutions

The Importance of Flux Core MIG Wire Manufacturers in Welding

Flux core MIG (Metal Inert Gas) welding has become a highly sought-after technique in various industries, ranging from construction to automotive repair. The effectiveness and versatility of this welding method largely depend on the quality of the wire used. This is where flux core MIG wire manufacturers play a crucial role in ensuring that welders have access to reliable, high-performance materials.

Understanding Flux Core MIG Welding

Flux core MIG welding uses a tubular wire filled with flux to create a protective gas shield during the welding process. This feature allows it to be used efficiently in outdoor environments and on thicker materials, making it particularly advantageous for a wide range of applications. The process is faster than traditional methods and allows for deeper penetration, leading to strong and durable welds. As industries evolve and demand for proficient welding increases, the role of quality welding materials becomes paramount.

Quality Matters

The quality of flux core MIG wire is essential for successful welding. Inferior wire can lead to defects, weak joints, and increased downtime, which is detrimental to production efficiency. Therefore, reputable flux core MIG wire manufacturers invest heavily in research, development, and quality control to ensure that their products meet stringent industry standards.

Manufacturers focus on various aspects such as wire composition, diameter, and flux type to produce wires that yield optimal results for different welding applications. For instance, different alloys and additives can enhance properties like tensile strength, corrosion resistance, and ease of use in various positions. This level of customization and attention to detail is what sets leading manufacturers apart from their competitors.

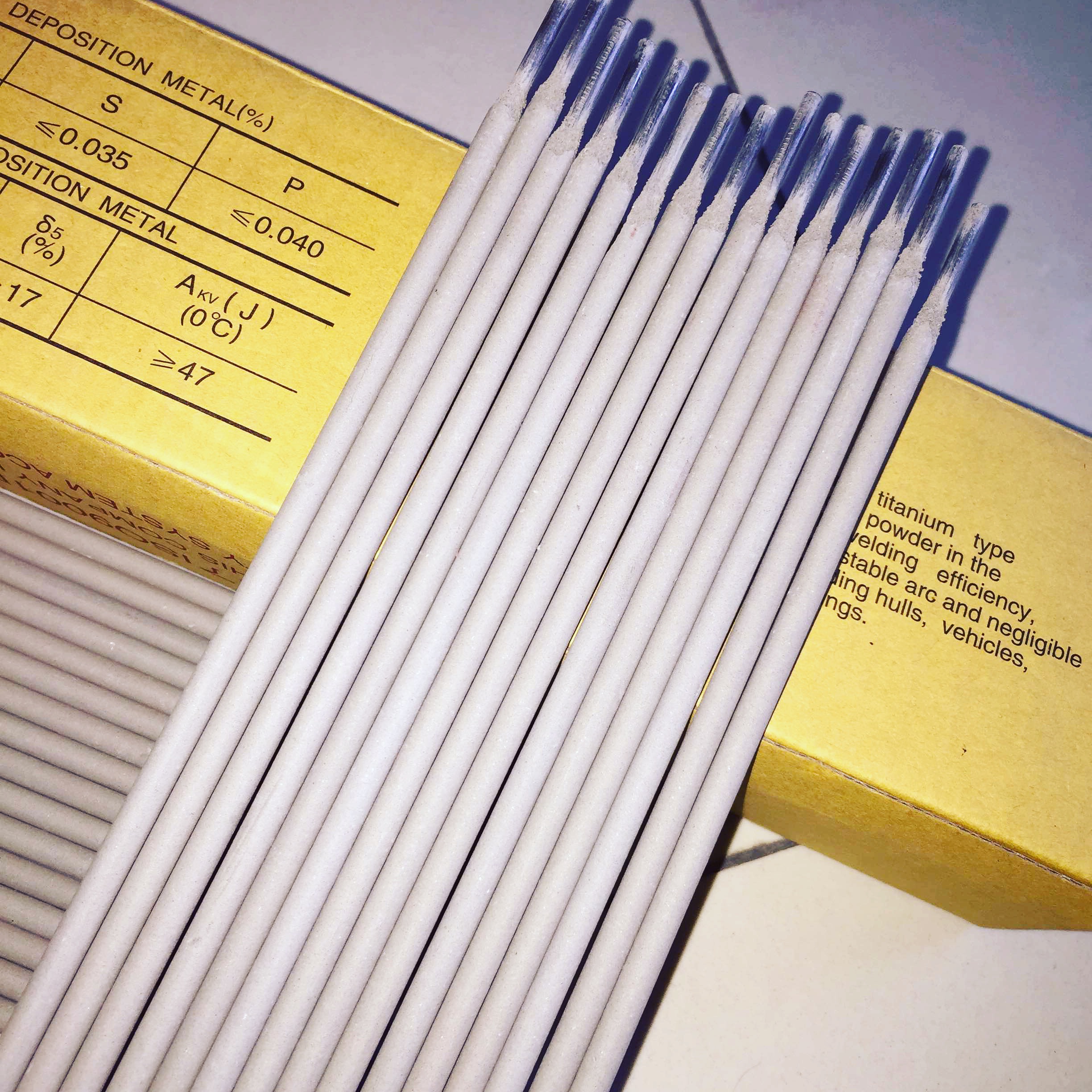

flux core mig wire manufacturer

Innovation and Technology

In a rapidly changing industrial landscape, flux core MIG wire manufacturers are continuously integrating advanced technology into their production processes. Automated systems, quality monitoring tools, and precision manufacturing techniques are employed to enhance efficiency and product quality. Moreover, many manufacturers are focusing on sustainability, creating wires that produce less smoke and spatter, thus making the welding process cleaner and more environmentally friendly.

Furthermore, extensive testing is a crucial part of the manufacturing process. Leading manufacturers conduct rigorous inspections and tests to ensure their wires perform optimally under various conditions. Close collaboration with end-users provides valuable feedback, enabling manufacturers to innovate and improve their product offerings continually.

Choosing the Right Manufacturer

For welding professionals and companies, selecting the right flux core MIG wire manufacturer is crucial. Factors to consider include the manufacturer’s reputation, product range, customer support, and adherence to industry standards. Reliable manufacturers will offer comprehensive technical support, helping users select the best wire for their specific applications.

In conclusion, flux core MIG wire manufacturers are vital players in the welding industry, contributing to the effectiveness and success of welding projects worldwide. With a focus on quality, innovation, and customer satisfaction, they ensure that welders have the right tools to achieve high-quality results, reinforcing the importance of choosing a trusted manufacturer for any welding endeavor.

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025