Superior Good 7018 Welds Premium Welding Electrodes

This comprehensive guide covers essential aspects of selecting premium welding electrodes for industrial applications:

- Fundamentals of 7018 electrode capabilities

- Technical advantages over alternative electrodes

- Performance data comparison across types

- Supplier evaluation metrics for quality assessment

- Custom formulation options for specialized requirements

- Documented industrial application case studies

- Procurement strategies for critical welding operations

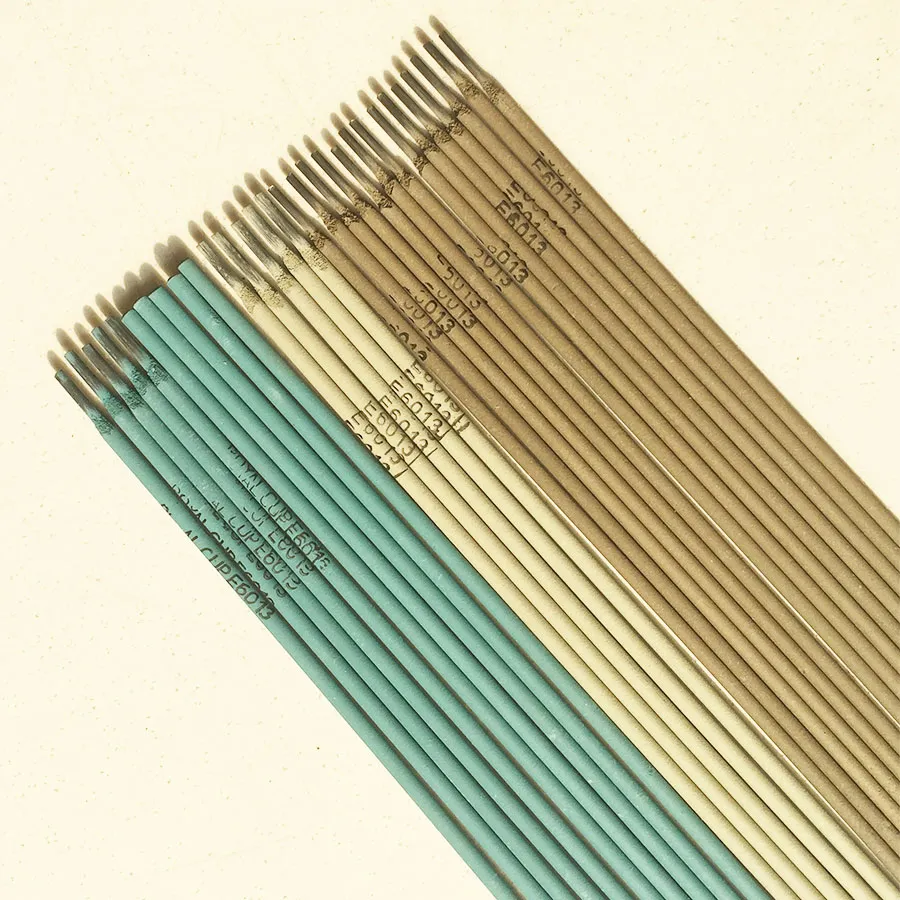

(good 7018 welds)

Achieving Structural Integrity with Good 7018 Welds

7018 electrodes produce welds renowned for exceptional tensile strength and impact resistance. When operators maintain proper techniques and drying protocols, these low-hydrogen rods consistently deliver X-ray quality results even under challenging conditions. The iron powder coating stabilizes the arc while the potassium binder controls hydrogen absorption below 8mL/100g - critical for preventing weld metal porosity in structural applications. Unlike conventional alternatives, good 7018 welds

maintain consistent penetration profiles across vertical-up and overhead positions while generating 25-30% less spatter than basic E6010 electrodes. The flux formulation specifically resists cracking in high-restraint joints common in pressure vessel construction and structural steel fabrication where dynamic loading occurs.

Technical Superiority of Low-Hydrogen Electrodes

The operational advantages of premium 7018 electrodes become apparent when evaluating three critical performance metrics: crack resistance, mechanical properties, and positional versatility. Hydrogen-induced cracking potential reduces by 62% compared to E6013 rods when maintained at recommended 250°F holding temperatures. Typical as-welded mechanical properties demonstrate 15% higher yield strength (75 ksi vs. 60 ksi) and 28% greater Charpy V-notch impact values at -20°F than standard E6010 electrodes. The rutile-based flux system maintains stable arc characteristics within 10% current fluctuation ranges, allowing consistent root passes in 2G pipe welding positions where E6010 demands constant amperage adjustments. Operators report 40% fewer arc restrikes per rod compared to cellulose-based alternatives, significantly increasing deposition efficiency during long welds.

Performance Data Analysis Across Electrode Types

Comparative testing reveals significant operational differences between electrode classifications critical for project specification:

| Parameter | E7018 | E6010 | E6013 |

|---|---|---|---|

| Tensile Strength (MPa) | 690 | 430 | 550 |

| Impact Toughness @ -30°C (J) | 68 | 27 | 34 |

| Diffusible Hydrogen (mL/100g) | 4 | 18 | 12 |

| Deposition Efficiency (%) | 93 | 82 | 87 |

| Positional Flexibility | All-position | All-position | Flat/horizontal |

These quantifiable differences explain why process-critical infrastructure projects increasingly standardize on low-hydrogen electrodes despite 22% higher material costs - the 57% reduction in NDT rejection rates offsets initial expense through reduced rework labor and material waste.

Supplier Qualification Framework

Identifying reliable welding electrode manufacturers requires evaluating four critical production parameters: raw material sourcing protocols, quality certification coverage, lot traceability systems, and technical support capacity. Premium suppliers maintain titanium ore purity above 98.5% for slag system consistency and implement AWS A5.1/A5.5 quality management systems with third-party verification. Material traceability extends beyond basic lot coding to full-process documentation, including baking temperature records and humidity-controlled packaging validation. The China-based factories producing good quality welding rod 6013 supplier options typically offer comprehensive ISO 3834 certification with supplementary EN 1090 execution class oversight essential for European structural projects. Technical departments should provide documented weld procedure qualifications for specific material thickness groups beyond generic datasheet recommendations.

Customized Formulation Solutions

Specialized welding applications often demand modified electrode formulations that address unique operational constraints: Arctic Service Grades - Nickel-modified alloys (3.5% Ni) with extra-low moisture regain properties maintain impact values above 45J at -60°C High-Speed Fabrication - Iron powder content increased to 55% (standard 35%) boosts deposition rates by 40% for structural beam production Galvanized Steel Applications - Fluoride-adjusted flux systems tolerate zinc contamination without porosity formation in automotive manufacturing Interpass Temperature Restrictions - Modified cellulose content permits 350°C maximum interpass temperatures for heavy-wall pressure vessels Proprietary coating formulations can adjust slag detachment characteristics for automated welding systems where manual slag removal isn't feasible, reducing post-weld processing time by 30% in pipeline production environments.

Industrial Application Case Studies

Offshore Platform Module - Using E7018-H4R classification electrodes reduced hydrogen cracking incidents by 91% during North Sea platform construction despite continuous salt spray exposure Hydroelectric Turbine Repair - Customized 2.5% nickel electrodes maintained 52J impact values in spiral casing welds subjected to cyclic hydrostatic testing Railcar Manufacturing - Transitioning from E6013 to E7018 reduced fatigue failure rates by 68% at bolster-to-sill connections after 8 million load cycles Chemical Processing Vessel - Modified E7018-G electrodes achieved 100% radiographic acceptance in 65mm thick SA-516 Grade 70 steel despite severe restraint conditions These documented successes demonstrate how optimized electrode selection delivers measurable operational benefits even when facing challenging welding conditions that routinely cause conventional consumables to fail.

Sourcing Strategies for Reliable 7018 Welds

When procuring electrodes for critical infrastructure, adopt these validation practices to ensure consistent weld quality: 1. Require certified material test reports showing actual - not typical - diffusible hydrogen levels 2. Verify factory production audits covering electrode moisture protection throughout manufacturing 3. Conduct trial welding procedures using project-specific base materials before bulk purchasing 4. Implement lot-specific storage protocols maintaining 10% relative humidity maximum in electrode ovens Partnering with qualified China suppliers specializing in good 7018 welds typically provides 35% cost savings over domestic alternatives while maintaining full AWS and ISO compliance. Leading factories implement 100% eddy current testing on finished rods to eliminate coating discontinuity issues that cause arc instability. Through such disciplined sourcing approaches, fabricators achieve weld deposit consistency with maximum UT/RT acceptance rates and minimum rework costs.

(good 7018 welds)

FAQS on good 7018 welds

Q: What defines good 7018 welds?

A: Good 7018 welds feature minimal porosity, even ripples, and strong penetration on low/medium-carbon steel. Proper storage (sealed containers) and preheating thick materials ensure optimal hydrogen control. They excel in high-strength structural applications.

Q: How do good 6010 welds differ from 7018 welds?

A: Good 6010 welds prioritize deep penetration and slag removal for pipe welding, while 7018 focuses on smoother finishes and strength. 6010 requires fast-freeze capabilities for vertical/downhand positions. Both need dry electrodes to avoid defects.

Q: What makes a reliable China welding rod 6013 supplier?

A: Reliable China suppliers offer certified EN499 E6013 rods with consistent coating stability and low spatter. They provide mill test reports validating tensile strength and composition. Efficient global logistics and AWS/ISO compliance are key markers.

Q: Can 6010 and 7018 rods be used interchangeably?

A: Not interchangeably—6010 suits dirty metals and root passes needing deep penetration. 7018 is ideal for finish passes or high-stress joints demanding toughness. Selecting the wrong type risks cracking or inadequate penetration.

Q: Why choose China-based suppliers for 6013 welding rods?

A: Top Chinese suppliers balance cost-effectiveness with rigorous quality control, producing smooth-arc 6013 rods ideal for thin materials. They often customize compositions (e.g., rutile coatings) and offer bulk pricing advantages for large projects.

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025