Premium Carbon Rods for Welding | Stable Arc & Precise Gouging

Industry Trends in Welding Electrodes for Carbon Steel Applications

The global market for welding consumables, particularly those designed for carbon steel, is experiencing dynamic shifts driven by advancements in metallurgy, automation, and stringent industrial standards. As industries like petrochemical, energy, shipbuilding, and construction continue to expand and modernize, the demand for high-performance and reliable carbon rods for welding sees consistent growth. Modern welding operations increasingly prioritize efficiency, weld quality, and welder comfort, leading to a surge in demand for electrodes offering superior arc stability, minimal spatter, and robust mechanical properties. Environmental regulations also play a crucial role, pushing manufacturers towards consumables with lower fume emissions and reduced hazardous material content. The evolution of welding techniques, from traditional Shielded Metal Arc Welding (SMAW) to more advanced automated processes, further necessitates the development of specialized welding rods capable of meeting diverse operational demands and material specifications.

Innovations in flux chemistry and core wire composition are continuously enhancing the performance characteristics of carbon steel welding electrodes, enabling their use in critical applications requiring high strength, excellent toughness, and exceptional corrosion resistance. The market is also seeing increased adoption of electrodes designed for all-position welding, improving productivity in complex fabrication projects. Furthermore, the rise of Industry 4.0 and digital integration in manufacturing processes underscores the importance of consistent product quality and traceability, making certified and reliable suppliers indispensable partners for B2B enterprises.

Manufacturing Process of High-Quality Carbon Steel Welding Electrodes

The production of high-performance carbon rods for welding, such as E6013 carbon steel welding electrodes, involves a meticulous multi-stage process designed to ensure metallurgical integrity, consistent performance, and adherence to international standards like AWS A5.1 and ISO 2560. This comprehensive process guarantees that each electrode delivers optimal arc characteristics and weld quality for critical applications.

Process Flow Overview:

- Core Wire Preparation: High-quality carbon steel wire rods are drawn to precise diameters. This cold drawing process enhances the wire's tensile strength and surface finish, crucial for consistent electrical conductivity and flux adhesion. Materials typically conform to international standards for low-carbon steel, ensuring minimal impurities and optimal mechanical properties in the final weld deposit.

- Flux Formulation and Mixing: The heart of the electrode's performance lies in its flux coating. This involves carefully proportioning various raw materials such as cellulose, rutile (titanium dioxide), silicates, carbonates, and deoxidizers. These components are accurately weighed, finely ground, and thoroughly mixed to create a homogeneous paste. The precise composition determines arc stability, slag detachability, penetration, and the mechanical properties of the weld metal.

- Extrusion Coating: The prepared core wire is fed into an extrusion machine where the flux paste is uniformly applied around it under high pressure. This process ensures a concentric and consistent coating thickness along the entire length of the electrode, which is vital for stable arc formation and even melting. CNC machining is often employed in the die design to maintain extremely tight tolerances.

- Baking and Drying: After extrusion, the green electrodes undergo a controlled baking and drying process in specialized ovens. This stage removes moisture from the flux coating, preventing hydrogen-induced cracking in the weld metal, and cures the binder agents, solidifying the coating structure. Precise temperature and humidity control are critical at this stage to achieve optimal mechanical properties and prevent defects.

- Tip and End Cleaning: The gripping end and the striking tip of the electrode are cleaned to remove flux coating, ensuring proper electrical contact with the electrode holder and easy arc initiation.

- Quality Control and Testing: Throughout the entire manufacturing process, rigorous quality control checks are implemented. This includes visual inspection, dimensional checks, coating eccentricity measurements, and comprehensive welding performance tests. Weld metal is subjected to destructive testing (tensile strength, yield strength, impact toughness, bend tests) and non-destructive testing (radiography, ultrasonic testing) to ensure compliance with standards such as ISO 9001 and AWS A5.1. Service life of these electrodes, when stored correctly, typically extends for several years without degradation of performance.

- Packaging: Finished electrodes are packaged in moisture-resistant materials, often vacuum-sealed, to protect them from environmental degradation during storage and transport, thereby preserving their optimal welding characteristics.

Our adherence to these stringent manufacturing protocols ensures that our carbon steel welding electrode products consistently deliver superior performance, reliability, and weld integrity in demanding industrial environments.

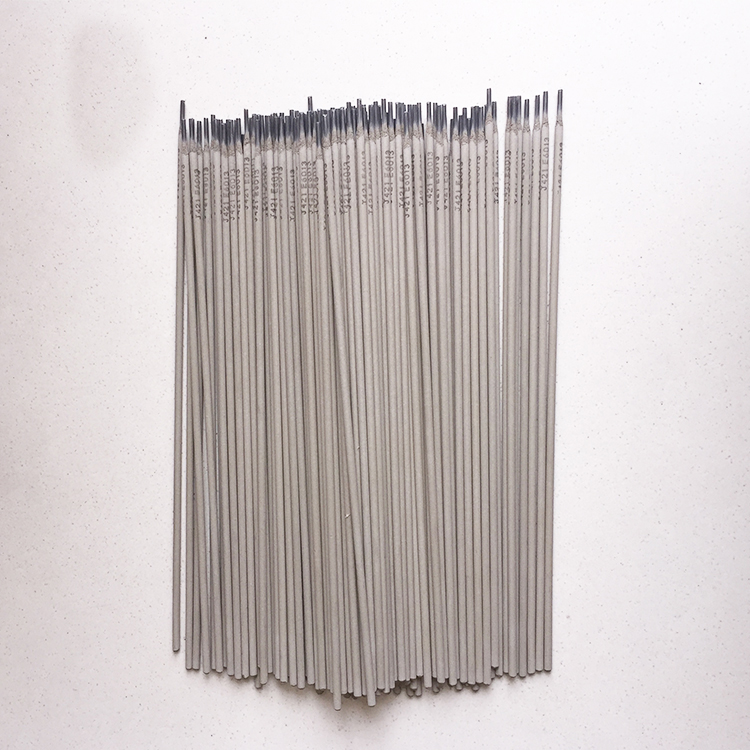

Image 1: Precision manufacturing of welding electrodes.

Technical Specifications of E6013 Carbon Steel Welding Electrodes

The E6013 welding electrode is a widely recognized and versatile general-purpose electrode for welding mild steels. Its rutile-based flux coating provides excellent arc stability, easy slag removal, and smooth bead appearance, making it a preferred choice for both professional welders and hobbyists. Below are the typical technical specifications for quality carbon steel welding rod products, conforming to AWS A5.1 standards.

Product Specification Table: E6013 Welding Electrode Rods for Carbon Steel

Note: Values are typical and may vary slightly based on specific manufacturer and batch. Always refer to the manufacturer's data sheet for precise specifications.

Image 2: Close-up of E6013 welding electrodes.

Application Scenarios and Technical Advantages

Our E6013 carbon sticks for welding are engineered for broad applicability across various industrial sectors, providing reliable and efficient solutions for joining mild and low-carbon steels. The inherent technical advantages of these electrodes make them indispensable in numerous challenging environments.

Target Industries & Typical Application Scenarios:

- Petrochemical Industry: Used in the fabrication and repair of non-pressure components, storage tanks, pipelines for non-corrosive fluids, and structural supports where mild steel is prevalent.

- Metallurgy & Heavy Manufacturing: Ideal for general fabrication of machinery components, frames, jigs, and fixtures within steel mills, foundries, and heavy equipment manufacturing.

- Shipbuilding & Marine: Utilized for the construction of ship hulls (non-critical sections), superstructures, deck fittings, and other mild steel components where good aesthetics and ease of use are priorities.

- Construction & Infrastructure: Employed in the erection of steel structures, bridges (non-primary load-bearing elements), railings, gates, and general architectural metalwork due to their versatility in all positions.

- Water Supply & Drainage Systems: Applicable for welding mild steel pipes, fittings, and tanks in water treatment plants and distribution networks, benefiting from their consistent weld quality.

- Automotive & Repair Workshops: Frequently used for bodywork, chassis repair, and general maintenance of vehicles and agricultural equipment, prized for their user-friendliness and clean finish.

Key Technical Advantages:

- Superior Arc Stability: The rutile-based flux ensures a soft, smooth, and very stable arc, making it easy to strike and maintain, even with low open-circuit voltage power sources. This contributes to energy saving by reducing power fluctuations and re-strikes.

- Excellent Weld Appearance: E6013 electrodes produce a finely rippled, smooth weld bead with minimal spatter, reducing post-weld cleaning and enhancing aesthetic quality, which is crucial in visible applications.

- All-Position Welding Capability: Designed for excellent performance in all welding positions (flat, horizontal, vertical-up, overhead), providing exceptional versatility and improving productivity in complex fabrication.

- Easy Slag Removal: The self-peeling or easily removable slag ensures quick cleanup, minimizing downtime and labor costs.

- Good Gap Bridging: These electrodes handle poor fit-up and wider gaps effectively, often found in repair or maintenance work, without sacrificing weld quality.

- Low Fume Generation: Compared to some other electrode types, E6013 generally produces lower fume levels, contributing to a healthier working environment and compliance with occupational safety standards. While not specifically designed for advanced corrosion resistance, the dense, smooth weld deposit offers good inherent resistance to atmospheric corrosion in mild steel applications.

Image 3: Welder using E6013 electrode in a fabrication shop.

Vendor Comparison and Customized Solutions

Selecting the right supplier for carbon rods for welding is paramount for ensuring consistent weld quality, operational efficiency, and cost-effectiveness. While many vendors offer E6013 electrodes, discerning B2B decision-makers prioritize several key factors beyond mere price.

Key Criteria for Vendor Comparison:

- Quality and Certifications: A reputable vendor will provide products conforming to international standards such as AWS A5.1 and ISO 2560. Certifications like ISO 9001 (Quality Management) and adherence to industry best practices are indicators of consistent product quality. Look for documented test reports and material safety data sheets (MSDS).

- Technical Expertise & Support: The ability of a vendor to offer technical guidance, troubleshooting, and application-specific recommendations demonstrates superior expertise. This includes support for specific welding parameters, material compatibility, and regulatory compliance.

- Supply Chain Reliability: Timely delivery, consistent stock availability, and robust logistics are crucial for uninterrupted production. Assess lead times, order fulfillment rates, and inventory management practices.

- Customization Capabilities: For unique projects or specific performance requirements, the ability to provide tailored solutions, such as specific electrode diameters, packaging sizes, or flux modifications, can be a significant advantage.

- Cost-Effectiveness & Value: Beyond the unit price, consider the total cost of ownership, including weld quality, reduction in rework, minimal spatter (reducing cleaning costs), and extended electrode shelf life.

Customized Solutions:

Recognizing that standard products may not always meet every unique project requirement, we offer bespoke solutions for our E6013 carbon steel welding electrode range. Our engineering team collaborates closely with clients to develop electrodes tailored to specific challenges:

- Specialized Packaging: For projects in harsh environments or with specific logistical needs, we can provide customized packaging to ensure electrode integrity and prevent moisture absorption.

- Diameter and Length Variations: While standard sizes are common, specific applications may benefit from non-standard diameters or lengths to optimize deposition rates or access restricted weld areas.

- Flux Chemistry Modifications: For unique metallurgical requirements, our R&D team can explore minor adjustments to flux composition to enhance properties like arc force, slag volume, or specific alloying elements (within the E6013 classification).

- Private Labeling & Branding: We offer private labeling services for distributors and large enterprises, allowing them to market high-quality electrodes under their own brand, backed by our manufacturing excellence.

Our decades of experience in the welding consumables industry, coupled with robust R&D capabilities, position us as an authoritative partner for tailored welding solutions. We leverage our deep understanding of material science and welding metallurgy to deliver products that not only meet but exceed client expectations.

Image 4: Quality control inspection of electrode batches.

Application Case Studies & Customer Experience

Our E6013 carbon rods for welding have consistently delivered exceptional results in diverse industrial applications, reflecting their reliability and performance. These case studies highlight real-world scenarios where our products provided significant value.

Case Study 1: Structural Steel Fabrication for a Logistics Hub

- Client: A leading construction firm specializing in large-scale industrial infrastructure.

- Challenge: The client needed to fabricate and erect several thousand tons of structural mild steel for a new logistics hub. The project demanded high productivity, consistent weld quality across multiple welding teams, and excellent aesthetic finish for visible structural elements.

- Solution: Our E6013 carbon steel welding electrodes (3.2mm and 4.0mm) were selected for their superior arc stability, easy slag release, and smooth bead profile. The electrodes' all-position capability significantly sped up the vertical and overhead welding tasks on-site.

- Results: The project was completed ahead of schedule, with a reported 15% reduction in post-weld grinding and cleaning due to minimal spatter and excellent bead appearance. Weld integrity was consistently high, passing all visual and non-destructive testing requirements, leading to significant cost savings and project efficiency.

Case Study 2: Maintenance and Repair in a Sugar Refinery

- Client: A major sugar processing plant undergoing routine maintenance and equipment repair during an annual shutdown.

- Challenge: The maintenance crew needed versatile welding electrodes to repair various mild steel components, including conveyor belts, structural frames, and non-pressure vessels. Welding conditions often involved less-than-ideal surface preparation and tight access areas.

- Solution: Our E6013 electrodes proved ideal for this environment due to their tolerance to rust and paint (within limits), excellent gap-bridging capabilities, and ease of re-striking. Their ability to perform well on AC and DC power sources provided flexibility for various portable welding machines.

- Results: The maintenance team experienced significantly reduced repair times. The ease of use and consistent performance minimized welder fatigue and improved overall productivity. The reliable welds ensured quick return to service for critical equipment, preventing costly downtime. "The consistent arc and easy slag make these our go-to rods for quick repairs," commented the lead maintenance engineer.

These case studies underscore our commitment to providing high-quality welding consumables that empower our clients to achieve their operational objectives efficiently and reliably. Our dedication to superior product performance and customer satisfaction has fostered strong partnerships with industrial leaders over our 20+ years of service in the market.

Image 5: Packaged electrodes ready for shipment to industrial clients.

Trustworthiness: FAQ, Lead Time, Warranty & Support

Establishing and maintaining trust with our B2B partners is fundamental to our operations. We achieve this through transparent processes, clear commitments, and robust customer support mechanisms for our carbon rods for welding products.

Frequently Asked Questions (FAQ):

Q: What is the recommended storage condition for E6013 electrodes?

A: E6013 electrodes should be stored in a dry environment at room temperature (15-25°C, 59-77°F) with relative humidity below 50%. While less prone to moisture absorption than low-hydrogen electrodes, proper storage extends their shelf life and ensures optimal performance. Avoid exposure to direct sunlight or extreme temperature fluctuations.

Q: Can E6013 electrodes be used for critical structural welds?

A: E6013 electrodes are excellent for general-purpose welding of mild steel, especially for applications where ease of use and good appearance are paramount. For highly critical structural applications that demand specific impact toughness or low-hydrogen properties, E7018 or similar low-hydrogen electrodes are typically recommended. Consult your welding engineer and relevant codes for specific project requirements.

Q: What welding machine settings are typical for E6013?

A: E6013 electrodes are very versatile and can be used with both AC and DC welding machines. For DC, they typically operate well on both DCEN (DC-) and DCEP (DC+). Amperage settings generally range from 40-80A for 2.5mm (3/32") electrodes, 70-120A for 3.2mm (1/8"), and 110-160A for 4.0mm (5/32"). Always start with the manufacturer's recommended settings and adjust based on joint configuration, material thickness, and desired penetration.

Lead Time & Fulfillment:

We maintain an optimized supply chain and robust inventory management system to ensure prompt delivery of our E6013 carbon sticks for welding. Standard orders for stock items typically have a lead time of 7-14 business days, depending on order volume and destination. For customized solutions or large-volume contracts, specific lead times will be provided upon consultation, ensuring transparency and predictability in your procurement planning.

Warranty Commitments:

We stand behind the quality of our E6013 welding electrodes. All products are warranted against defects in material and workmanship for a period of 12 months from the date of purchase, provided they are stored and used according to recommended guidelines. Our commitment to ISO 9001 standards underpins our dedication to product excellence and customer satisfaction.

Customer Support:

Our dedicated customer support team and technical specialists are available to assist with product inquiries, application advice, and after-sales support. We offer multi-channel support via phone, email, and online inquiry forms. For complex technical challenges, our welding engineers can provide expert consultations to ensure you derive maximum value from our welding consumables.

Contact us today to discuss your specific welding needs and how our solutions can contribute to your operational success. Our goal is to be a reliable and authoritative partner in your welding supply chain.

References

- American Welding Society (AWS) A5.1/A5.1M:2004, Specification for Carbon Steel Electrodes for Shielded Metal Arc Welding.

- International Organization for Standardization (ISO) 2560:2009, Welding consumables — Covered electrodes for manual metal arc welding of non-alloy and fine grain steels — Classification.

- The Welding Institute (TWI), "Shielded Metal Arc Welding (SMAW)," www.twi-global.com (Accessed 2023-10-27).

- ASM International, "Welding and Joining, Volume 6," ASM Handbook, 1993.

- Journal of Manufacturing Processes, "Advances in Welding Electrode Materials," Volume 24, 2016.

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025