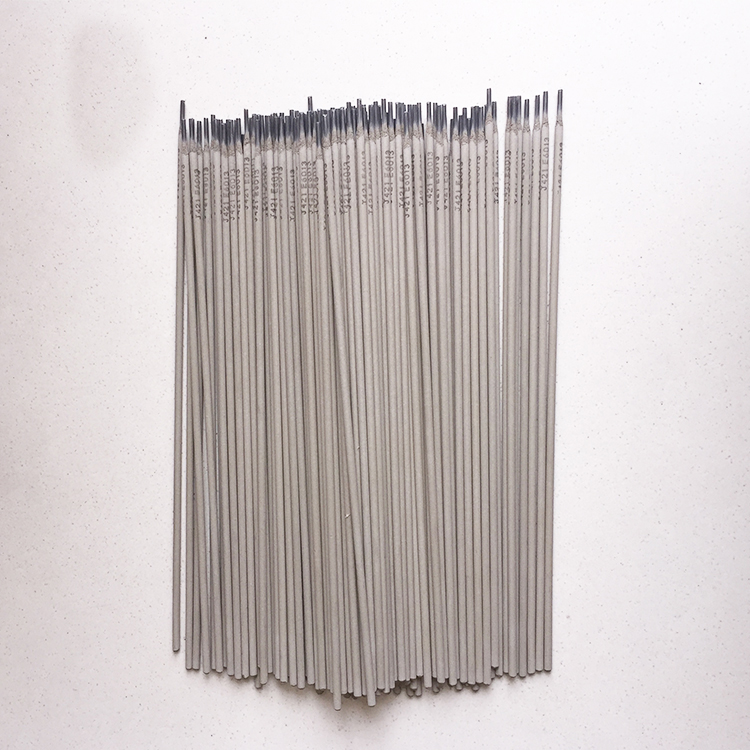

Carbon Rods for Welding – High Conductivity & Durability

Insider’s guide to carbon rods for welding: why E6013 still wins on the shop floor

If you’re sifting through options for carbon rods for welding, here’s the short version: E6013 remains the dependable, easy-going all‑positions pick for carbon steel. I’ve watched many fab shops return to it after flirting with flashier consumables. Why? Smooth arc, forgiving puddle, and frankly, it just gets parts out the door.

What’s trending (and what actually matters)

Demand is shifting to reliable, AC-friendly electrodes with easy restrike for repair and light fabrication. In fact, many customers say they value arc stability and low spatter over tiny gains in deposition rate. E6013 nails that balance, especially on thin sheet and out-of-position welds.

Product snapshot: E6013 Welding Electrode Rods for carbon steel

Origin: NO.368 YOUYI NORTH STREET, XINHUA DISTRICT, SHIJIAZHUANG CITY, CHINA. To be honest, the factory location matters less than consistent flux coating and bake discipline—but this supplier has both.

| Parameter | Spec (≈/range; real-world use may vary) |

|---|---|

| Classification | AWS A5.1/SFA‑5.1 E6013; ISO 2560‑A E 38 0 R 12 |

| Diameters | 2.0 / 2.5 / 3.2 / 4.0 mm |

| Polarity | AC / DC± |

| Positions | All positions |

| Typical tensile strength | ≈ 430–480 MPa (≥ 60 ksi min) |

| Elongation | ≈ 22–28% |

| Arc behavior | Stable, low spatter, easy slag removal, quick restrike |

How it’s made (and tested)

Materials: low‑carbon steel core wire + rutile‑potassium flux with deoxidizers. Methods: wire drawing, flux extrusion, precision coating, and controlled baking (≈ 350°C cure; shop re‑dry 70–110°C if needed). Testing: AWS A5.1 mechanicals, bend tests, fillet break, and diffusible hydrogen spot checks. Certifications commonly include ISO 9001; MTRs available on request.

Service life: sealed shelf life ≈ 12 months; keep dry, recondition before critical work. Industries: general fabrication, maintenance, light structural, ship repair, ag equipment, and auto body (thin gauge). Many users report friendlier puddle control than E6011 on sheet.

Real-world use tips

- Current (3.2 mm): around 90–130 A; keep a short arc.

- Work angle ≈ 15–30°; whip slightly on vertical‑up.

- On rusty steel: quick pass to clean, then finish—this rod is forgiving, but not magical.

Vendor snapshot: comparing options

| Vendor | Origin | Certs | MOQ | Lead time | Notes |

|---|---|---|---|---|---|

| SteelTools China (E6013) | Shijiazhuang, CN | ISO 9001; AWS classification | ≈ 1–2 tons | 2–4 weeks | Stable arc, custom branding |

| Brand A (import) | Mixed | ISO 9001 | ≈ 3 tons | 4–6 weeks | Good on AC; price higher |

| Local distributor | Regional | — | By case | Stock dependent | Fast delivery; batch variability |

Customization, feedback, and mini case studies

Customization: private label, carton printing, and tailored current windows per diameter. One buyer requested slightly thicker flux for vertical‑up; the tweak helped bead wet‑out—surprisingly noticeable.

carbon rods for welding in auto‑body: a Midwest shop switched from 6011 to E6013 on 1.6 mm sheet; burn‑throughs dropped ≈ 30%, rework fell sharply. In ship repair, a crew praised easy restrike inside tight compartments—less fiddling with stubs, more welding.

Test data (typical, not guaranteed)

- UTS: ≈ 450 MPa; YS: ≈ 360 MPa; Elongation: ≈ 24%.

- Macro/fillet break: sound fusion on A36 plate per WPS based on AWS D1.1.

- Hydrogen: low to moderate for rutile class; follow bake guidance.

Bottom line: if you need carbon rods for welding that play nicely with AC buzz boxes, thin material, and all‑position jobs, E6013 is still a smart, economical choice.

Authoritative references

- AWS A5.1/A5.1M: Specification for Carbon Steel Electrodes for Shielded Metal Arc Welding.

- ISO 2560‑A: Welding consumables — Covered electrodes for manual metal arc welding of non‑alloy and fine grain steels.

- ASME Section II, Part C (SFA‑5.1): Harmonized classification for E6013.

- OSHA 1910.252: Welding, Cutting, and Brazing — safety practices for fume control and storage.

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025