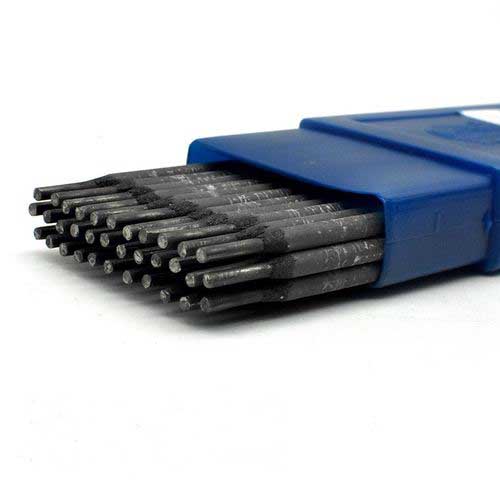

Cast Iron Welding Rod Electrode AWS ENi-Cl - Strong & Machinable

Introduction to Advanced Cast Iron Welding Solutions

In industrial maintenance and fabrication, the repair and joining of cast iron components present unique metallurgical challenges. These challenges necessitate specialized consumables that can overcome issues like brittleness, crack sensitivity, and graphite flake structure. This comprehensive guide focuses on the Cast Iron Welding Rod Electrode AWS ENi-Cl, a nickel-based electrode specifically designed for these demanding applications. Its formulation ensures superior weldability, high strength, and excellent ductility, making it indispensable across a multitude of heavy industries. We delve into its manufacturing process, technical merits, diverse applications, and the robust support systems available for our B2B partners.

Manufacturing Process: Precision Engineering for Superior Performance

The production of a high-quality Cast Iron Welding Rod Electrode AWS ENi-Cl is a meticulously controlled multi-stage process, designed to ensure consistent performance and reliability. Every step is rigorously monitored to meet stringent international standards such as ISO 9001 and ANSI specifications.

Process Flow Diagram for AWS ENi-Cl Electrode Manufacturing

- Core Wire Preparation: High-purity nickel or a nickel-iron alloy wire is selected, precision-drawn to specific diameters, and cleaned to remove surface contaminants. This forms the conductive core.

- Flux Formulation & Mixing: A complex blend of mineral and chemical powders (e.g., calcium carbonate, rutile, cellulose, iron powder, deoxidizers, arc stabilizers) is precisely weighed and mixed in controlled environments. The specific ratio determines the electrode's arc characteristics, slag properties, and metallurgical composition of the weld deposit.

- Extrusion Coating: The prepared flux mixture is then extruded onto the core wire under high pressure. This process requires precise control over coating thickness and concentricity to ensure uniform arc stability and consistent weld metal deposition.

- Baking & Drying: The freshly coated electrodes are subjected to a controlled baking and drying process. This removes moisture, solidifies the flux coating, and enhances its mechanical integrity, preventing hydrogen embrittlement in the weld.

- Tip End & Markings: The electrodes are then tipped (to facilitate arc striking) and marked with product identification, diameter, and AWS classification (ENi-Cl).

- Quality Control & Testing: Each batch undergoes rigorous testing, including chemical analysis of the weld deposit, mechanical property tests (tensile strength, elongation, hardness), radiographic inspection for internal defects, and practical welding tests to assess usability and arc characteristics.

- Packaging: Finally, the electrodes are hermetically sealed in moisture-proof packaging to maintain their integrity and performance until use.

Key Materials: The core wire for Cast Iron Welding Rod Electrode AWS ENi-Cl primarily consists of nickel (typically >90%), which offers superior compatibility with cast iron's high carbon content, preventing carbide formation and promoting a ductile, machinable weld. The flux coating is meticulously formulated to provide good slag release, minimal spatter, and stable arc characteristics.

Testing Standards: Our electrodes conform to international standards including AWS A5.15, ISO 1071, and EN ISO 2560. Each batch is subjected to comprehensive testing protocols covering mechanical properties, chemical composition, and radiographic soundness, ensuring that they meet or exceed industry benchmarks for performance and safety.

Service Life & Advantages: The inherent corrosion resistance and excellent mechanical properties of welds made with Cast Iron Welding Rod Electrode AWS ENi-Cl contribute to an extended service life for repaired components. In typical application scenarios, these electrodes demonstrate significant advantages such as energy saving through reduced pre-heating requirements for certain repairs, superior crack resistance in brittle materials, and exceptional resistance to various corrosive media, critical in industries like petrochemical and water treatment.

Industry Trends in Cast Iron Welding

The landscape of cast iron welding is continually evolving, driven by demands for increased efficiency, environmental compliance, and enhanced material performance. Current trends indicate a strong push towards electrodes that offer improved cold welding capabilities, minimizing the need for extensive pre-heating and post-weld heat treatment, which directly translates to energy savings and reduced downtime. There's also a growing emphasis on low-fume and low-spatter formulations to improve welder safety and workplace conditions. Furthermore, the industry is seeing an increase in the repair-versus-replace paradigm for large, complex cast iron components, making the selection of reliable, high-performance electrodes like Cast Iron Welding Rod Electrode AWS ENi-Cl more critical than ever. Automation and robotic welding for repetitive tasks, even in repair scenarios, are also influencing the demand for electrodes with highly consistent arc characteristics.

Technical Specifications and Performance Data

The performance of the Cast Iron Welding Rod Electrode AWS ENi-Cl is defined by its robust technical specifications, which assure optimal outcomes in challenging cast iron welding applications. These electrodes are characterized by their high nickel content, which provides a weld deposit with a low coefficient of thermal expansion, significantly reducing residual stresses and the likelihood of cracking in brittle cast iron.

Typical Weld Metal Chemical Composition (%) (All Weld Metal)

| Element | Typical Value (%) | AWS A5.15 Limit (%) |

|---|---|---|

| Nickel (Ni) | 96.0 min | 85.0 min |

| Carbon (C) | 0.50 max | 1.0 max |

| Manganese (Mn) | 1.00 max | 2.5 max |

| Silicon (Si) | 0.50 max | 1.0 max |

| Iron (Fe) | Balance | 8.0 max |

Typical Weld Metal Mechanical Properties (All Weld Metal)

| Property | Typical Value | AWS A5.15 Requirement |

|---|---|---|

| Tensile Strength (MPa) | 380 - 450 | Min. 340 |

| Yield Strength (MPa) | 250 - 300 | N/A |

| Elongation (%) | 15 - 25 | Min. 5 |

| Hardness (HB) | 150 - 200 | N/A (Machinable) |

| Welding Current | AC or DC (+) | AC or DC (+) |

The low hardness and excellent ductility of the weld deposit, as indicated by the elongation values, are crucial for achieving machinable welds, which is often a primary requirement for cast iron repairs. This prevents common issues such as porosity and hard spots that can compromise post-weld machining operations.

Application Scenarios and Target Industries

The versatility and high performance of the Cast Iron Welding Rod Electrode AWS ENi-Cl make it suitable for an extensive range of applications, particularly in industries where cast iron components are prevalent and critical for operations.

Primary Target Industries:

- Petrochemical & Oil & Gas: Repair of pump casings, valve bodies, compressor housings, and engine blocks exposed to corrosive media and high pressures.

- Metallurgy & Mining: Restoration of heavy machinery parts, gearbox housings, rolling mill components, and furnace doors.

- Water Supply & Drainage: Repair of large diameter cast iron pipes, fittings, impellers, and pump bodies in municipal and industrial water systems.

- Power Generation: Maintenance of steam turbine casings, generator frames, and engine components.

- Automotive & Heavy Equipment: Repair of engine blocks, cylinder heads, exhaust manifolds, and transmission casings.

Typical Application Scenarios:

- Crack Repair: Effectively repairs cracks in gray, ductile, and malleable cast irons, restoring structural integrity without significant pre-heating in many cases.

- Building Up Worn Surfaces: Ideal for restoring worn or damaged surfaces to original dimensions, extending the lifespan of costly components.

- Joining Dissimilar Metals: Can be used for joining cast iron to steel where appropriate, providing a strong, durable bond.

- Repair of Machining Defects: Filling holes or defects caused by machining errors, ensuring components meet specifications.

Technical Advantages and Performance Benefits

The selection of Cast Iron Welding Rod Electrode AWS ENi-Cl offers a multitude of technical advantages that directly translate into operational efficiencies and cost savings for industrial clients.

- Superior Crack Resistance: The high nickel content of the weld metal provides excellent ductility and a low coefficient of thermal expansion, minimizing shrinkage stresses and significantly reducing the risk of cracking in the heat-affected zone (HAZ) of brittle cast irons. This is a critical advantage over electrodes with higher iron content.

- Exceptional Machinability: The weld deposit is soft and easily machinable, allowing for post-weld finishing operations without issues of hard spots or tool wear. This is paramount for components requiring precise dimensional accuracy after repair.

- Low Hydrogen Content: Our manufacturing process ensures minimal moisture in the flux coating, reducing the potential for hydrogen-induced cracking, especially crucial for sensitive cast iron repairs.

- Good Corrosion Resistance: The high nickel content imparts good resistance to corrosion from various chemicals and environmental factors, extending the service life of repaired parts in aggressive operating conditions.

- Versatile Welding Positions: Designed for all-position welding, offering flexibility and ease of use in complex repair geometries.

- Minimal Pre-heating Requirements: While pre-heating is often recommended for very thick or highly restrained sections, Cast Iron Welding Rod Electrode AWS ENi-Cl can often be used with minimal or no pre-heat for many repairs, significantly saving time and energy.

- Stable Arc & Smooth Operation: The expertly formulated flux coating provides a stable, smooth arc with low spatter and easy slag removal, enhancing welder productivity and weld quality.

Vendor Comparison: Why Choose Our AWS ENi-Cl Electrodes

When evaluating suppliers for critical welding consumables like Cast Iron Welding Rod Electrode AWS ENi-Cl, discerning B2B clients look beyond mere price. Our commitment to quality, technical support, and consistent product performance sets us apart in a competitive market.

Comparative Advantages:

| Feature | Our AWS ENi-Cl Electrode | Typical Competitor Electrode (Standard Grade) |

|---|---|---|

| Weld Deposit Machinability | Excellent (Soft, no hard spots) | Good to Moderate (Risk of hard spots) |

| Crack Resistance | Superior (High ductility, low thermal expansion) | Good (Higher risk in restrained welds) |

| Arc Stability & Spatter | Very Stable, Minimal Spatter | Good, Moderate Spatter |

| Quality Certifications | ISO 9001, AWS A5.15, EN ISO 2560 | AWS A5.15 (may vary in scope) |

| Technical Support | Dedicated application engineers, on-site support | Standard product support |

| Product Consistency | High (Rigorous batch testing) | Moderate (Standard QC) |

Our reputation for authoritative product quality is built on decades of manufacturing excellence and a deep understanding of metallurgical science. We prioritize consistent performance, ensuring that every batch of Cast Iron Welding Rod Electrode AWS ENi-Cl meets the highest standards. Our rigorous quality control processes, including independent third-party verification, provide an unparalleled level of trustworthiness and reliability.

Customized Solutions and Technical Consultation

Recognizing that every industrial application has unique challenges, we offer tailored solutions beyond standard product offerings. Our team of experienced metallurgical engineers provides expert technical consultation to assist clients in optimizing their welding processes and selecting the most appropriate consumables for highly specialized repairs.

- Application-Specific Guidance: We provide detailed advice on welding procedures, pre-heating and post-heating requirements, interpass temperatures, and joint designs for specific cast iron grades and component geometries.

- Material Compatibility Analysis: Our experts can analyze the base metal composition to recommend the most effective welding strategy and ensure metallurgical compatibility with the Cast Iron Welding Rod Electrode AWS ENi-Cl.

- Batch Customization: For large-volume projects with highly specific requirements, we can explore custom batch formulations to optimize certain characteristics (e.g., slightly modified manganese or silicon content for specialized cast iron alloys), always adhering to AWS ENi-Cl core standards.

- Training & Workshops: We offer on-site or virtual training for welding teams to ensure proper application techniques and maximize the performance of our electrodes.

This commitment to partnership and problem-solving highlights our dedication to not just selling products, but delivering comprehensive welding solutions that add substantial value to our clients' operations.

Application Case Studies: Proven Performance in Real-World Scenarios

Our Cast Iron Welding Rod Electrode AWS ENi-Cl has been instrumental in numerous successful repair and fabrication projects across diverse industries, demonstrating its reliability and superior performance.

Case Study 1: Large Industrial Pump Housing Repair

- Challenge: A major petrochemical plant experienced a critical failure in a large gray cast iron pump housing, developing a 30 cm crack. Replacement costs were prohibitive, and lead times were unacceptable.

- Solution: Using Cast Iron Welding Rod Electrode AWS ENi-Cl (4.0mm diameter), a highly skilled team repaired the crack. Minimal pre-heating (150°C) was applied due to the electrode's low-stress deposit properties.

- Outcome: The repair was successful, showing excellent crack resistance and achieving a fully machinable weld. The pump was back in service within 48 hours, saving the client estimated costs of over $250,000 in replacement parts and downtime. Post-weld non-destructive testing confirmed the integrity of the repair.

Case Study 2: Vintage Engine Block Restoration

- Challenge: A specialized restoration company needed to repair a severely corroded and cracked engine block from a vintage industrial diesel engine. The casting was irreplaceable.

- Solution: After careful joint preparation, our Cast Iron Welding Rod Electrode AWS ENi-Cl was selected for its exceptional machinability and low heat input characteristics, crucial for preserving the integrity of the old casting. Welders applied multiple passes, carefully controlling interpass temperature.

- Outcome: The repair provided a sound, dense weld metal that was easily blended and machined back to original specifications. The engine block was fully restored, preserving a valuable historical asset and exceeding the client's expectations for both structural integrity and cosmetic finish.

Frequently Asked Questions (FAQ)

Q: What types of cast iron can the AWS ENi-Cl electrode weld?

A: It is primarily designed for welding gray, ductile (nodular), and malleable cast irons. It can also be used for joining cast iron to steel.

Q: Is pre-heating always required when using this electrode?

A: For most repairs, minimal or no pre-heating is required. However, for heavily restrained sections, very thick components, or complex castings, a mild pre-heat (e.g., 100-200°C / 200-400°F) is recommended to minimize thermal shock and stress.

Q: What polarity is recommended for the AWS ENi-Cl electrode?

A: It can be used with either AC or DC reverse polarity (DCEP, electrode positive), with DC+ generally providing a smoother arc and better penetration control.

Q: Is the weld deposit machinable?

A: Yes, the weld metal deposited by Cast Iron Welding Rod Electrode AWS ENi-Cl is soft and easily machinable, making it ideal for repairs on components that require post-weld machining.

Lead Time, Warranty, and Customer Support

We understand the critical nature of timely delivery and reliable support in industrial operations. Our logistics and customer service are tailored to meet B2B demands with efficiency and professionalism.

Lead Time & Fulfillment:

- Standard Orders: Typically 3-5 business days for stock items, with expedited shipping options available upon request.

- Bulk & Custom Orders: Lead times will be quoted based on volume and specific requirements, generally ranging from 2-4 weeks. We maintain robust inventory levels to support continuous demand.

- Global Shipping: We leverage a network of trusted logistics partners to ensure prompt and secure delivery worldwide.

Warranty Commitments:

All our Cast Iron Welding Rod Electrode AWS ENi-Cl products are backed by a comprehensive warranty, guaranteeing freedom from defects in material and workmanship for a period of 12 months from the date of purchase, provided they are stored and used according to our specifications. We are committed to standing behind the quality and performance of our electrodes.

Customer Support:

Our dedicated technical support team comprises experienced welding engineers and metallurgists available to assist with product selection, application guidance, troubleshooting, and post-sales inquiries. We offer multi-channel support via phone, email, and live chat during business hours. For complex projects, on-site technical assistance can be arranged. We are committed to ensuring our clients achieve optimal results with our products.

References

- American Welding Society (AWS) A5.15/A5.15M:2009. Specification for Welding Electrodes and Rods for Cast Iron.

- International Organization for Standardization (ISO) 1071:2010. Welding consumables - Covered electrodes, wires, rods and tubular cored electrodes for fusion welding of cast iron - Classification.

- Metal Joining and Welding. ASM International. ISBN: 978-0-87170-653-8.

- Fundamentals of Welding Metallurgy. AWS Publications. ISBN: 978-0-87171-805-0.

- The Welding Handbook, Volume 2: Welding Processes. AWS Publications. ISBN: 978-0-87171-700-8.

-

What is a medium-frequency pulse? What types of welding are suitable for?NewsNov.24,2025

-

Why is the overall cost of CO2 welding lower than that of shielded metal arc welding?NewsNov.21,2025

-

Welding Knowledge 6NewsNov.20,2025

-

What is a low-frequency pulse? What types of welding are they suitable for?NewsNov.19,2025

-

Why are the weld joints from CO₂ gas shielded welding of such high quality?NewsNov.18,2025

-

J506 Welding Rod - Low Hydrogen, All-Position, AC/DC E7016NewsNov.17,2025

Cast Iron Welding Rod Electrode AWS ENi-Cl - Strong & Machinable

Introduction to Advanced Cast Iron Welding Solutions

In industrial maintenance and fabrication, the repair and joining of cast iron components present unique metallurgical challenges. These challenges necessitate specialized consumables that can overcome issues like brittleness, crack sensitivity, and graphite flake structure. This comprehensive guide focuses on the Cast Iron Welding Rod Electrode AWS ENi-Cl, a nickel-based electrode specifically designed for these demanding applications. Its formulation ensures superior weldability, high strength, and excellent ductility, making it indispensable across a multitude of heavy industries. We delve into its manufacturing process, technical merits, diverse applications, and the robust support systems available for our B2B partners.

Manufacturing Process: Precision Engineering for Superior Performance

The production of a high-quality Cast Iron Welding Rod Electrode AWS ENi-Cl is a meticulously controlled multi-stage process, designed to ensure consistent performance and reliability. Every step is rigorously monitored to meet stringent international standards such as ISO 9001 and ANSI specifications.

Process Flow Diagram for AWS ENi-Cl Electrode Manufacturing

- Core Wire Preparation: High-purity nickel or a nickel-iron alloy wire is selected, precision-drawn to specific diameters, and cleaned to remove surface contaminants. This forms the conductive core.

- Flux Formulation & Mixing: A complex blend of mineral and chemical powders (e.g., calcium carbonate, rutile, cellulose, iron powder, deoxidizers, arc stabilizers) is precisely weighed and mixed in controlled environments. The specific ratio determines the electrode's arc characteristics, slag properties, and metallurgical composition of the weld deposit.

- Extrusion Coating: The prepared flux mixture is then extruded onto the core wire under high pressure. This process requires precise control over coating thickness and concentricity to ensure uniform arc stability and consistent weld metal deposition.

- Baking & Drying: The freshly coated electrodes are subjected to a controlled baking and drying process. This removes moisture, solidifies the flux coating, and enhances its mechanical integrity, preventing hydrogen embrittlement in the weld.

- Tip End & Markings: The electrodes are then tipped (to facilitate arc striking) and marked with product identification, diameter, and AWS classification (ENi-Cl).

- Quality Control & Testing: Each batch undergoes rigorous testing, including chemical analysis of the weld deposit, mechanical property tests (tensile strength, elongation, hardness), radiographic inspection for internal defects, and practical welding tests to assess usability and arc characteristics.

- Packaging: Finally, the electrodes are hermetically sealed in moisture-proof packaging to maintain their integrity and performance until use.

Key Materials: The core wire for Cast Iron Welding Rod Electrode AWS ENi-Cl primarily consists of nickel (typically >90%), which offers superior compatibility with cast iron's high carbon content, preventing carbide formation and promoting a ductile, machinable weld. The flux coating is meticulously formulated to provide good slag release, minimal spatter, and stable arc characteristics.

Testing Standards: Our electrodes conform to international standards including AWS A5.15, ISO 1071, and EN ISO 2560. Each batch is subjected to comprehensive testing protocols covering mechanical properties, chemical composition, and radiographic soundness, ensuring that they meet or exceed industry benchmarks for performance and safety.

Service Life & Advantages: The inherent corrosion resistance and excellent mechanical properties of welds made with Cast Iron Welding Rod Electrode AWS ENi-Cl contribute to an extended service life for repaired components. In typical application scenarios, these electrodes demonstrate significant advantages such as energy saving through reduced pre-heating requirements for certain repairs, superior crack resistance in brittle materials, and exceptional resistance to various corrosive media, critical in industries like petrochemical and water treatment.

Industry Trends in Cast Iron Welding

The landscape of cast iron welding is continually evolving, driven by demands for increased efficiency, environmental compliance, and enhanced material performance. Current trends indicate a strong push towards electrodes that offer improved cold welding capabilities, minimizing the need for extensive pre-heating and post-weld heat treatment, which directly translates to energy savings and reduced downtime. There's also a growing emphasis on low-fume and low-spatter formulations to improve welder safety and workplace conditions. Furthermore, the industry is seeing an increase in the repair-versus-replace paradigm for large, complex cast iron components, making the selection of reliable, high-performance electrodes like Cast Iron Welding Rod Electrode AWS ENi-Cl more critical than ever. Automation and robotic welding for repetitive tasks, even in repair scenarios, are also influencing the demand for electrodes with highly consistent arc characteristics.

Technical Specifications and Performance Data

The performance of the Cast Iron Welding Rod Electrode AWS ENi-Cl is defined by its robust technical specifications, which assure optimal outcomes in challenging cast iron welding applications. These electrodes are characterized by their high nickel content, which provides a weld deposit with a low coefficient of thermal expansion, significantly reducing residual stresses and the likelihood of cracking in brittle cast iron.

Typical Weld Metal Chemical Composition (%) (All Weld Metal)

| Element | Typical Value (%) | AWS A5.15 Limit (%) |

|---|---|---|

| Nickel (Ni) | 96.0 min | 85.0 min |

| Carbon (C) | 0.50 max | 1.0 max |

| Manganese (Mn) | 1.00 max | 2.5 max |

| Silicon (Si) | 0.50 max | 1.0 max |

| Iron (Fe) | Balance | 8.0 max |

Typical Weld Metal Mechanical Properties (All Weld Metal)

| Property | Typical Value | AWS A5.15 Requirement |

|---|---|---|

| Tensile Strength (MPa) | 380 - 450 | Min. 340 |

| Yield Strength (MPa) | 250 - 300 | N/A |

| Elongation (%) | 15 - 25 | Min. 5 |

| Hardness (HB) | 150 - 200 | N/A (Machinable) |

| Welding Current | AC or DC (+) | AC or DC (+) |

The low hardness and excellent ductility of the weld deposit, as indicated by the elongation values, are crucial for achieving machinable welds, which is often a primary requirement for cast iron repairs. This prevents common issues such as porosity and hard spots that can compromise post-weld machining operations.

Application Scenarios and Target Industries

The versatility and high performance of the Cast Iron Welding Rod Electrode AWS ENi-Cl make it suitable for an extensive range of applications, particularly in industries where cast iron components are prevalent and critical for operations.

Primary Target Industries:

- Petrochemical & Oil & Gas: Repair of pump casings, valve bodies, compressor housings, and engine blocks exposed to corrosive media and high pressures.

- Metallurgy & Mining: Restoration of heavy machinery parts, gearbox housings, rolling mill components, and furnace doors.

- Water Supply & Drainage: Repair of large diameter cast iron pipes, fittings, impellers, and pump bodies in municipal and industrial water systems.

- Power Generation: Maintenance of steam turbine casings, generator frames, and engine components.

- Automotive & Heavy Equipment: Repair of engine blocks, cylinder heads, exhaust manifolds, and transmission casings.

Typical Application Scenarios:

- Crack Repair: Effectively repairs cracks in gray, ductile, and malleable cast irons, restoring structural integrity without significant pre-heating in many cases.

- Building Up Worn Surfaces: Ideal for restoring worn or damaged surfaces to original dimensions, extending the lifespan of costly components.

- Joining Dissimilar Metals: Can be used for joining cast iron to steel where appropriate, providing a strong, durable bond.

- Repair of Machining Defects: Filling holes or defects caused by machining errors, ensuring components meet specifications.

Technical Advantages and Performance Benefits

The selection of Cast Iron Welding Rod Electrode AWS ENi-Cl offers a multitude of technical advantages that directly translate into operational efficiencies and cost savings for industrial clients.

- Superior Crack Resistance: The high nickel content of the weld metal provides excellent ductility and a low coefficient of thermal expansion, minimizing shrinkage stresses and significantly reducing the risk of cracking in the heat-affected zone (HAZ) of brittle cast irons. This is a critical advantage over electrodes with higher iron content.

- Exceptional Machinability: The weld deposit is soft and easily machinable, allowing for post-weld finishing operations without issues of hard spots or tool wear. This is paramount for components requiring precise dimensional accuracy after repair.

- Low Hydrogen Content: Our manufacturing process ensures minimal moisture in the flux coating, reducing the potential for hydrogen-induced cracking, especially crucial for sensitive cast iron repairs.

- Good Corrosion Resistance: The high nickel content imparts good resistance to corrosion from various chemicals and environmental factors, extending the service life of repaired parts in aggressive operating conditions.

- Versatile Welding Positions: Designed for all-position welding, offering flexibility and ease of use in complex repair geometries.

- Minimal Pre-heating Requirements: While pre-heating is often recommended for very thick or highly restrained sections, Cast Iron Welding Rod Electrode AWS ENi-Cl can often be used with minimal or no pre-heat for many repairs, significantly saving time and energy.

- Stable Arc & Smooth Operation: The expertly formulated flux coating provides a stable, smooth arc with low spatter and easy slag removal, enhancing welder productivity and weld quality.

Vendor Comparison: Why Choose Our AWS ENi-Cl Electrodes

When evaluating suppliers for critical welding consumables like Cast Iron Welding Rod Electrode AWS ENi-Cl, discerning B2B clients look beyond mere price. Our commitment to quality, technical support, and consistent product performance sets us apart in a competitive market.

Comparative Advantages:

| Feature | Our AWS ENi-Cl Electrode | Typical Competitor Electrode (Standard Grade) |

|---|---|---|

| Weld Deposit Machinability | Excellent (Soft, no hard spots) | Good to Moderate (Risk of hard spots) |

| Crack Resistance | Superior (High ductility, low thermal expansion) | Good (Higher risk in restrained welds) |

| Arc Stability & Spatter | Very Stable, Minimal Spatter | Good, Moderate Spatter |

| Quality Certifications | ISO 9001, AWS A5.15, EN ISO 2560 | AWS A5.15 (may vary in scope) |

| Technical Support | Dedicated application engineers, on-site support | Standard product support |

| Product Consistency | High (Rigorous batch testing) | Moderate (Standard QC) |

Our reputation for authoritative product quality is built on decades of manufacturing excellence and a deep understanding of metallurgical science. We prioritize consistent performance, ensuring that every batch of Cast Iron Welding Rod Electrode AWS ENi-Cl meets the highest standards. Our rigorous quality control processes, including independent third-party verification, provide an unparalleled level of trustworthiness and reliability.

Customized Solutions and Technical Consultation

Recognizing that every industrial application has unique challenges, we offer tailored solutions beyond standard product offerings. Our team of experienced metallurgical engineers provides expert technical consultation to assist clients in optimizing their welding processes and selecting the most appropriate consumables for highly specialized repairs.

- Application-Specific Guidance: We provide detailed advice on welding procedures, pre-heating and post-heating requirements, interpass temperatures, and joint designs for specific cast iron grades and component geometries.

- Material Compatibility Analysis: Our experts can analyze the base metal composition to recommend the most effective welding strategy and ensure metallurgical compatibility with the Cast Iron Welding Rod Electrode AWS ENi-Cl.

- Batch Customization: For large-volume projects with highly specific requirements, we can explore custom batch formulations to optimize certain characteristics (e.g., slightly modified manganese or silicon content for specialized cast iron alloys), always adhering to AWS ENi-Cl core standards.

- Training & Workshops: We offer on-site or virtual training for welding teams to ensure proper application techniques and maximize the performance of our electrodes.

This commitment to partnership and problem-solving highlights our dedication to not just selling products, but delivering comprehensive welding solutions that add substantial value to our clients' operations.

Application Case Studies: Proven Performance in Real-World Scenarios

Our Cast Iron Welding Rod Electrode AWS ENi-Cl has been instrumental in numerous successful repair and fabrication projects across diverse industries, demonstrating its reliability and superior performance.

Case Study 1: Large Industrial Pump Housing Repair

- Challenge: A major petrochemical plant experienced a critical failure in a large gray cast iron pump housing, developing a 30 cm crack. Replacement costs were prohibitive, and lead times were unacceptable.

- Solution: Using Cast Iron Welding Rod Electrode AWS ENi-Cl (4.0mm diameter), a highly skilled team repaired the crack. Minimal pre-heating (150°C) was applied due to the electrode's low-stress deposit properties.

- Outcome: The repair was successful, showing excellent crack resistance and achieving a fully machinable weld. The pump was back in service within 48 hours, saving the client estimated costs of over $250,000 in replacement parts and downtime. Post-weld non-destructive testing confirmed the integrity of the repair.

Case Study 2: Vintage Engine Block Restoration

- Challenge: A specialized restoration company needed to repair a severely corroded and cracked engine block from a vintage industrial diesel engine. The casting was irreplaceable.

- Solution: After careful joint preparation, our Cast Iron Welding Rod Electrode AWS ENi-Cl was selected for its exceptional machinability and low heat input characteristics, crucial for preserving the integrity of the old casting. Welders applied multiple passes, carefully controlling interpass temperature.

- Outcome: The repair provided a sound, dense weld metal that was easily blended and machined back to original specifications. The engine block was fully restored, preserving a valuable historical asset and exceeding the client's expectations for both structural integrity and cosmetic finish.

Frequently Asked Questions (FAQ)

Q: What types of cast iron can the AWS ENi-Cl electrode weld?

A: It is primarily designed for welding gray, ductile (nodular), and malleable cast irons. It can also be used for joining cast iron to steel.

Q: Is pre-heating always required when using this electrode?

A: For most repairs, minimal or no pre-heating is required. However, for heavily restrained sections, very thick components, or complex castings, a mild pre-heat (e.g., 100-200°C / 200-400°F) is recommended to minimize thermal shock and stress.

Q: What polarity is recommended for the AWS ENi-Cl electrode?

A: It can be used with either AC or DC reverse polarity (DCEP, electrode positive), with DC+ generally providing a smoother arc and better penetration control.

Q: Is the weld deposit machinable?

A: Yes, the weld metal deposited by Cast Iron Welding Rod Electrode AWS ENi-Cl is soft and easily machinable, making it ideal for repairs on components that require post-weld machining.

Lead Time, Warranty, and Customer Support

We understand the critical nature of timely delivery and reliable support in industrial operations. Our logistics and customer service are tailored to meet B2B demands with efficiency and professionalism.

Lead Time & Fulfillment:

- Standard Orders: Typically 3-5 business days for stock items, with expedited shipping options available upon request.

- Bulk & Custom Orders: Lead times will be quoted based on volume and specific requirements, generally ranging from 2-4 weeks. We maintain robust inventory levels to support continuous demand.

- Global Shipping: We leverage a network of trusted logistics partners to ensure prompt and secure delivery worldwide.

Warranty Commitments:

All our Cast Iron Welding Rod Electrode AWS ENi-Cl products are backed by a comprehensive warranty, guaranteeing freedom from defects in material and workmanship for a period of 12 months from the date of purchase, provided they are stored and used according to our specifications. We are committed to standing behind the quality and performance of our electrodes.

Customer Support:

Our dedicated technical support team comprises experienced welding engineers and metallurgists available to assist with product selection, application guidance, troubleshooting, and post-sales inquiries. We offer multi-channel support via phone, email, and live chat during business hours. For complex projects, on-site technical assistance can be arranged. We are committed to ensuring our clients achieve optimal results with our products.

References

- American Welding Society (AWS) A5.15/A5.15M:2009. Specification for Welding Electrodes and Rods for Cast Iron.

- International Organization for Standardization (ISO) 1071:2010. Welding consumables - Covered electrodes, wires, rods and tubular cored electrodes for fusion welding of cast iron - Classification.

- Metal Joining and Welding. ASM International. ISBN: 978-0-87170-653-8.

- Fundamentals of Welding Metallurgy. AWS Publications. ISBN: 978-0-87171-805-0.

- The Welding Handbook, Volume 2: Welding Processes. AWS Publications. ISBN: 978-0-87171-700-8.