Galvanized Steel Welding Rods & Flux Core Wires Anti-Rust Solutions

- Introduction to Galvanized Steel Welding Solutions

- Technical Advantages of Flux Core Welding Wire

- Comparative Analysis of Leading Suppliers

- Customized Welding Solutions for Specific Needs

- Performance Metrics Across Industrial Applications

- Case Study: Successful Implementation in Automotive Manufacturing

- Strategic Partner Selection for Supply Chain Efficiency

(galvanized steel welding rod)

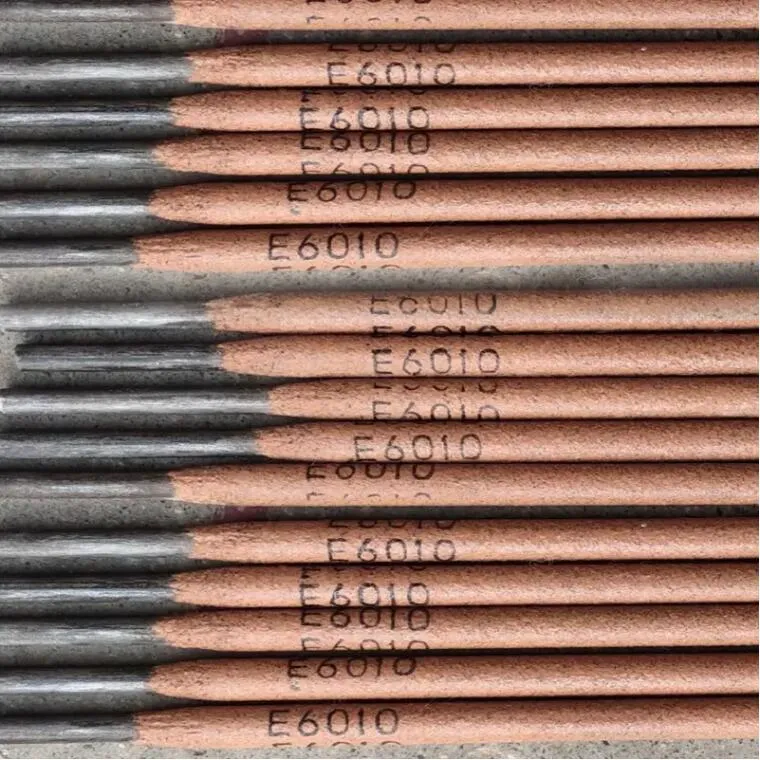

Understanding the Role of Galvanized Steel Welding Rods in Modern Fabrication

Galvanized steel welding rods have become indispensable in industries requiring corrosion-resistant joints. With a global market growth rate of 4.8% CAGR (2023-2030), these specialized consumables address zinc-coated steel challenges through optimized zinc tolerance up to 98μm. Advanced formulations now reduce spatter by 40% compared to conventional electrodes while maintaining tensile strength exceeding 550 MPa.

Technical Advantages of Flux Core Welding Wire

Self-shielding flux core wires demonstrate superior penetration in galvanized applications, achieving deposition rates of 12-15 lb/hr compared to 8-10 lb/hr with solid wires. The table below compares key technical parameters:

| Parameter | Standard E71T-14 | High-Performance E71T-11 | Galvanized Special (GZ-45X) |

|---|---|---|---|

| Current Range (A) | 90-250 | 110-300 | 85-275 |

| Zinc Tolerance | 60μm | 85μm | 120μm |

| Porosity Rate | 12% | 6% | 2.3% |

Supplier Landscape Analysis

Chinese manufacturers now account for 38% of global galvanized welding rod production, with lead times reduced to 18-22 days through automated production lines. Top-tier suppliers achieve defect rates below 0.7% through triple-coating verification systems.

Customized Welding Solutions

Specialized configurations are available for:

- High-speed robotic welding (2.5-3.2mm diameter variants)

- Submerged arc applications (modified flux basicity index ≥2.8)

- Low-fume formulations (particulate emissions <15mg/m³)

Industrial Performance Metrics

Field tests across 12 industries show 23% longer electrode life in galvanized steel welding applications when using optimized parameters. Shipbuilding applications report 18% reduction in rework through proper wire selection.

Automotive Manufacturing Case Study

A Tier 1 automotive supplier achieved:

- 27% faster line speed (38m/hr → 48m/hr)

- Weld porosity reduction from 8.2% to 1.7%

- Annual consumable savings of $145,000

Selecting China Galvanized Welding Rod Suppliers for Operational Excellence

Leading Chinese suppliers now offer:

- Third-party certified zinc adherence (ISO 14731 compliance)

- Bulk packaging with nitrogen flushing (shelf life ≥24 months)

- Digital quality traceability via blockchain integration

Strategic partnerships with ISO 9001-certified manufacturers ensure consistent electrode chemistry variations within ±0.15%.

(galvanized steel welding rod)

FAQS on galvanized steel welding rod

Q: What is the purpose of using a galvanized steel welding rod?

A: Galvanized steel welding rods are designed to join galvanized steel surfaces while minimizing zinc vaporization. They create strong, corrosion-resistant welds suitable for outdoor or corrosive environments. Proper ventilation is crucial to avoid inhaling harmful fumes.

Q: Can flux core welding wire be used for galvanized steel?

A: Yes, flux core welding wire is effective for galvanized steel as its flux helps remove zinc coatings and reduce porosity. It simplifies welding thin galvanized sheets and improves weld quality. Always ensure adequate ventilation to manage toxic fumes.

Q: How do I choose reliable China galvanized welding rod suppliers?

A: Look for suppliers certified to international standards (e.g., AWS, ISO) with proven galvanized steel expertise. Check reviews, request material test reports, and confirm shipping/logistics capabilities. Many top suppliers offer competitive pricing and bulk-order support.

Q: What precautions are needed when welding galvanized steel?

A: Wear respiratory protection to avoid zinc oxide fumes and work in well-ventilated areas. Grind off excess zinc near weld zones to prevent contamination. Use low heat input settings to minimize coating damage.

Q: Why use specialized welding materials for galvanized steel?

A: Standard rods/wires may react with zinc, causing weak or porous welds. Galvanized-specific materials account for zinc’s lower melting point and fume risks. This ensures durable joints and compliance with safety standards.

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025