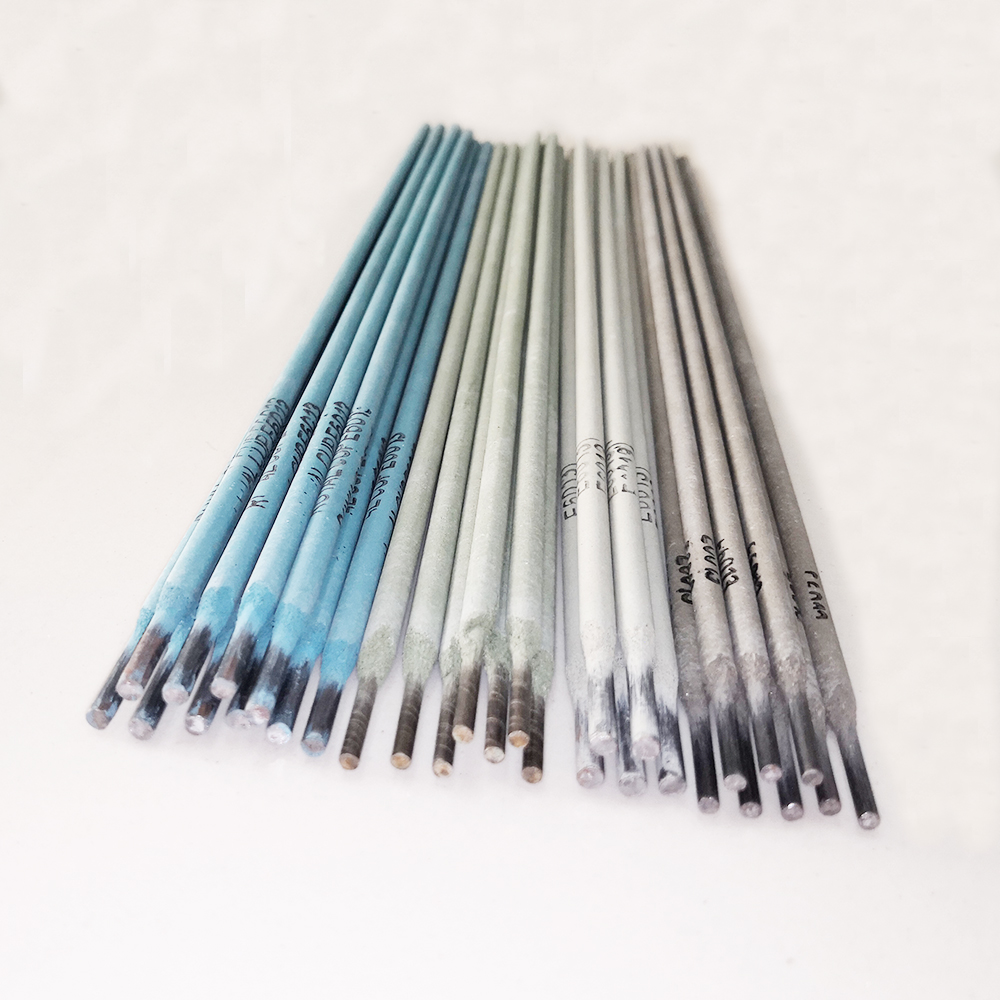

AWS E6013 Welding Electrodes: All-Position & Smooth Arc Rods

Industry Trends and Significance of AWS E6013 Welding Electrodes

In the dynamic landscape of industrial fabrication and construction, the selection of appropriate welding consumables is paramount for achieving structural integrity, operational efficiency, and cost-effectiveness. Among the diverse array of electrodes available, the aws e6013 welding electrodes hold a significant position. Renowned for their versatility and ease of use, these general-purpose electrodes are indispensable across a multitude of applications, from light fabrication and maintenance work to general structural welding.

Current industry trends indicate a sustained demand for user-friendly welding solutions that offer excellent arc stability, minimal spatter, and good slag detachability. The emphasis is on enhancing productivity without compromising weld quality, especially in sectors facing skilled labor shortages. The aws e6013 welding electrodes align perfectly with these requirements, providing a stable arc on both AC and DC welding machines, making them a preferred choice for workshops, on-site repairs, and educational facilities. The continuous evolution in flux formulations also aims at improving deposition rates and mechanical properties, further solidifying the E6013’s role as a workhorse electrode. Furthermore, sustainability initiatives are driving demand for electrodes that produce less fume and slag, pushing manufacturers to innovate within the E6013 classification to meet evolving environmental and safety standards.

Technical Specifications and Performance Parameters

The classification "E6013" itself conveys critical technical information. According to AWS A5.1/A5.1M, 'E' denotes an electrode, '60' signifies a minimum tensile strength of 60,000 PSI, '1' indicates that it can be used in all positions (flat, horizontal, vertical, overhead), and '3' specifies the type of coating and current characteristics (rutile type, suitable for AC and DC current, typically with a soft, stable arc and easy slag removal). Understanding these parameters is crucial for B2B decision-makers and welding engineers to match the electrode to specific project demands.

Typical Mechanical Properties (as-welded)

The rutile-based flux coating of the aws e6013 welding electrodes is primarily composed of titanium dioxide, which provides an easily ionizing arc, excellent bead appearance, and a soft arc characteristics. This contributes to minimal spatter and easy slag removal, significantly reducing post-weld cleaning time. Moreover, its ability to tolerate poor fit-up and contaminated surfaces to some extent makes it highly practical for diverse field conditions.

Manufacturing Process Flow for AWS E6013 Welding Electrodes

The production of high-quality aws e6013 welding electrodes is a sophisticated process, meticulously controlled to ensure consistent performance and adherence to international standards like ISO 2560 and AWS A5.1. The core of these electrodes is a precisely drawn steel wire, typically made from low-carbon steel (e.g., AISI 1008 or 1010), onto which a specialized flux coating is applied.

Detailed Manufacturing Steps:

- Core Wire Preparation: High-quality steel rods are drawn through a series of dies to achieve the desired diameter and surface finish. This drawing process enhances the tensile strength and ensures a uniform electrical conductivity. The wire undergoes cleaning to remove any drawing lubricants or oxides.

- Flux Mixture Preparation: The flux, a proprietary blend of rutile (titanium dioxide), cellulose, silicates, and deoxidizers, is carefully weighed and mixed in a high-speed mixer. Water glass (sodium silicate) or potassium silicate is added as a binder to form a plastic, workable paste. The precise composition is critical for arc stability, slag properties, and mechanical characteristics of the weld metal.

-

Coating Extrusion: The prepared flux paste is extruded onto the core wire. The wire passes through a die where the flux is applied under high pressure, ensuring a concentric and uniform coating thickness. This process is crucial for preventing arc blow and maintaining consistent electrical properties during welding.

[Core Wire Spool] | V [Wire Drawing & Cleaning] | V [Flux Mixing & Kneading] | V [Extrusion Die & Coating] <--- Precise control of concentricity | V [Head & Tip Cleaning] | V [Baking Ovens] <--- Temperature & Humidity controlled | V [Final Inspection & Packaging] - Head and Tip Cleaning: After extrusion, the ends of the electrodes are cleaned to remove flux, exposing the bare wire for electrical contact in the electrode holder and for arc striking.

- Baking and Drying: The coated electrodes are then transferred to controlled baking ovens. This process removes moisture from the flux coating, which is essential to prevent hydrogen-induced cracking in the weld metal. The baking temperature and duration are carefully monitored to achieve optimal mechanical properties and prevent excessive moisture pick-up during storage.

- Quality Control and Packaging: Finished electrodes undergo rigorous testing for concentricity, coating integrity, mechanical properties of weld metal (tensile strength, yield strength, impact), and welding characteristics (arc stability, spatter, slag removal). Only electrodes meeting ISO and ANSI/AWS standards are packaged for distribution.

The typical service life of an aws e6013 welding rod is dictated by proper storage conditions. When stored in a dry environment at recommended temperatures, they maintain their integrity for several years. Target industries benefiting from this robust manufacturing process include shipbuilding, general fabrication, pipeline maintenance, and various civil construction projects.

Application Scenarios and Technical Advantages

The versatility of aws e6013 welding electrodes makes them highly adaptable to a wide array of application scenarios, particularly where ease of use and aesthetic bead appearance are prioritized. Their stable arc and shallow penetration make them ideal for welding thin materials and for situations requiring cosmetic welds.

Key Application Industries:

- General Fabrication & Maintenance: Widely used for fabricating light to medium structures, machinery repairs, and general workshop tasks due to their all-position capability and forgiving arc characteristics.

- Petrochemical Industry: For non-critical structural components, platforms, and pipe supports where general strength and good appearance are needed, not necessarily high-pressure vessel integrity.

- Metallurgy & Mining: Repair of non-critical equipment, structural bracing, and maintenance in facilities where various metal thicknesses are encountered.

- Water Supply & Drainage Systems: Fabrication of water tanks, pipelines (non-pressure), and supports, benefiting from the electrode's ease of use and good bead profile.

- Agricultural Equipment: Repair and fabrication of farm machinery, trailers, and implements where ease of use and adaptability to varying conditions are crucial.

Typical Advantages in Application Scenarios:

- Energy Saving: The stable arc and efficient metal transfer reduce arc-on time, contributing to energy savings, especially in repetitive welding tasks.

- Corrosion Resistance: While not designed for highly corrosive environments, the weld metal provides adequate resistance for general atmospheric exposure, particularly when paired with appropriate base metals and post-weld treatments.

- Ease of Use: Excellent for novice welders and for situations where welding skill levels may vary. The soft arc and easy strike make it very forgiving.

- Aesthetic Bead Appearance: Produces a smooth, fine-rippled bead with minimal spatter, reducing the need for extensive grinding or finishing.

- All-Positional Capability: Can be used in flat, horizontal, vertical-up, vertical-down, and overhead positions, offering maximum flexibility on complex structures.

- Good Slag Detachability: The slag is typically easy to remove, often peeling off by itself, saving valuable time in production environments.

Vendor Comparison and Customized Solutions

When sourcing aws e6013 welding electrodes, B2B purchasers face a landscape of numerous manufacturers. While the AWS classification ensures a baseline level of performance, subtle differences in flux composition, manufacturing precision, and quality control can lead to variations in arc characteristics, spatter levels, and overall user experience. Leading manufacturers distinguish themselves through consistent quality, comprehensive technical support, and the ability to offer tailored solutions.

Comparative Analysis of E6013 Characteristics Across Vendors:

Customized Solutions:

For large industrial clients or projects with unique requirements, customization of aws e6013 welding electrodes can offer significant advantages. This might include:

- Specialized Packaging: For instance, vacuum-sealed packaging for enhanced moisture protection in humid environments, or specific carton counts for automated feeding systems.

- Optimized Diameters/Lengths: While standard sizes prevail, some applications might benefit from non-standard dimensions to optimize deposition rates or reach confined spaces.

- Flux Modifications: Minor adjustments to flux chemistry can fine-tune properties such as arc force, spatter reduction, or slag fluidity, though this generally moves beyond the strict E6013 classification towards proprietary formulations.

- Branding & Logistics: Private labeling and tailored logistics solutions, including just-in-time delivery for large-scale projects, are common offerings from experienced manufacturers.

Application Case Studies and Customer Trust

The proven track record of aws e6013 welding electrodes in real-world applications is the strongest testament to their reliability. Our company, with years of dedicated service in the welding consumables industry, has partnered with numerous clients across various sectors, delivering consistent performance and fostering long-term trust.

Case Study 1: Large-Scale Industrial Enclosure Fabrication

A major client in the manufacturing sector, specializing in large industrial enclosures for electrical switchgear, sought an electrode that combined high deposition rates with excellent bead appearance for their mild steel components (up to 10mm thickness). After evaluating several options, they standardized on our China welding rod 6013 welding electrodes. The key outcomes included a 15% reduction in post-weld grinding due to minimal spatter and smooth bead profile, a 10% increase in production speed owing to superior arc stability and easy restrike, and significantly positive feedback from welders regarding ease of use and reduced fatigue. This project highlighted the E6013's capacity for high-volume, quality-critical fabrication.

Case Study 2: On-Site Agricultural Equipment Repair

A national agricultural cooperative frequently required robust electrodes for on-site repairs of various farm machinery, often in less-than-ideal environmental conditions. The challenge was finding an electrode that performed reliably on both clean and lightly contaminated surfaces, using portable AC welders. Our aws e6013 welding electrodes were chosen for their exceptional tolerance to varying conditions and their ability to produce strong, reliable welds even with limited power sources. Customer feedback emphasized the electrode’s "forgiveness" and the quick, effective repairs it enabled, minimizing downtime for critical equipment during harvest seasons. This underscores its utility for practical, immediate solutions in challenging environments.

Our adherence to international standards such as ISO 9001 for quality management and rigorous internal testing procedures ensures that every batch of electrodes meets stringent performance criteria. We are proud to serve a diverse portfolio of clients, ranging from small fabrication shops to multinational corporations, cementing our reputation as an authoritative and trustworthy supplier.

Trustworthiness: FAQ, Lead Time, Warranty & Support

Frequently Asked Questions (FAQ)

-

Q: What welding positions are E6013 electrodes suitable for?

A: AWS E6013 electrodes are suitable for all welding positions: flat, horizontal, vertical-up, vertical-down, and overhead. -

Q: Can E6013 electrodes be used with both AC and DC welding machines?

A: Yes, E6013 electrodes are designed for use with both AC (alternating current) and DC (direct current) power sources, offering excellent versatility. -

Q: What types of materials are best welded with E6013?

A: They are primarily used for welding mild steels and some low-alloy steels. They are excellent for light to medium fabrication and general repair work. -

Q: How should E6013 electrodes be stored to maintain their quality?

A: To prevent moisture absorption, electrodes should be stored in a dry environment at room temperature, ideally in sealed container111s or heated storage cabinets if humidity is a concern.

Lead Time and Fulfillment

We maintain robust inventory levels for our standard range of aws e6013 welding electrodes to ensure rapid fulfillment. Typical lead times for standard orders are 3-7 business days, depending on order volume and destination. For large-scale or customized orders, specific lead times will be provided upon consultation, factoring in production schedules and logistics. Our efficient supply chain management and strategic warehousing aim to minimize delivery delays, supporting your project timelines effectively.

Warranty Commitments

All our welding electrodes are backed by a comprehensive quality warranty, guaranteeing adherence to AWS A5.1/A5.1M and ISO 2560 standards. We warrant our products against defects in material and workmanship for a period of 12 months from the date of purchase, provided they are stored and used according to recommended guidelines. Our commitment to quality ensures that our electrodes perform as specified, delivering consistent and reliable weld outcomes.

Customer Support Information

Our dedicated team of technical experts and customer service professionals is available to provide unparalleled support. From product selection guidance and application advice to troubleshooting and post-purchase assistance, we ensure that our clients receive timely and informed responses. For inquiries, technical specifications, or support, please contact us via our website, phone, or email. We are committed to fostering strong, long-term relationships with our B2B partners by providing exceptional products and steadfast support.

References

- American Welding Society (AWS) A5.1/A5.1M:2017, Specification for Carbon Steel Electrodes for Shielded Metal Arc Welding. Miami, FL: American Welding Society.

- International Organization for Standardization (ISO) 2560:2020, Welding consumables — Covered electrodes for manual metal arc welding of non-alloy and fine grain steels — Classification. Geneva, Switzerland: ISO.

- The Welding Institute (TWI) Job Knowledge for Welders - Arc Welding: E6013 Electrodes. Granta Park, Cambridge, UK: TWI.

- Lincoln Electric Co., The Procedure Handbook of Arc Welding. Cleveland, OH: Lincoln Electric Co.

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025