Pipeline Welding Electrodes: Low-Hydrogen, High Toughness

Field Notes on Pipeline Welding: What Really Matters in E6010 Electrodes

If you work pipe in the real world—5G, 6G, windy right-of-way, tight tie-ins—you already know why pipeline welding electrodes still own the root pass. E6010’s cellulose arc digs in, bites through oxides, and lets you keyhole with confidence. I’ve watched crews swear by them and—occasionally—swear at them. But when they’re matched to the pipe and procedure, they deliver.

Industry pulse

Three trends stand out: (1) contractors want consistent arc starts for orbital tie-ins and manual 6G, (2) inspection is getting stricter—more jobs are held to API 1104 with radiography—and (3) supply stability matters. One northern operator told me, “We lost days chasing a substitute brand.” That’s why origin and capacity matter. This E6010 line comes from NO.368 YOUYI NORTH STREET, XINHUA DISTRICT, SHIJIAZHUANG CITY, CHINA; the factory reports >80,000 metric tons annual electrode output, which—if accurate—helps with big bids.

Product snapshot: E6010 cellulose rod

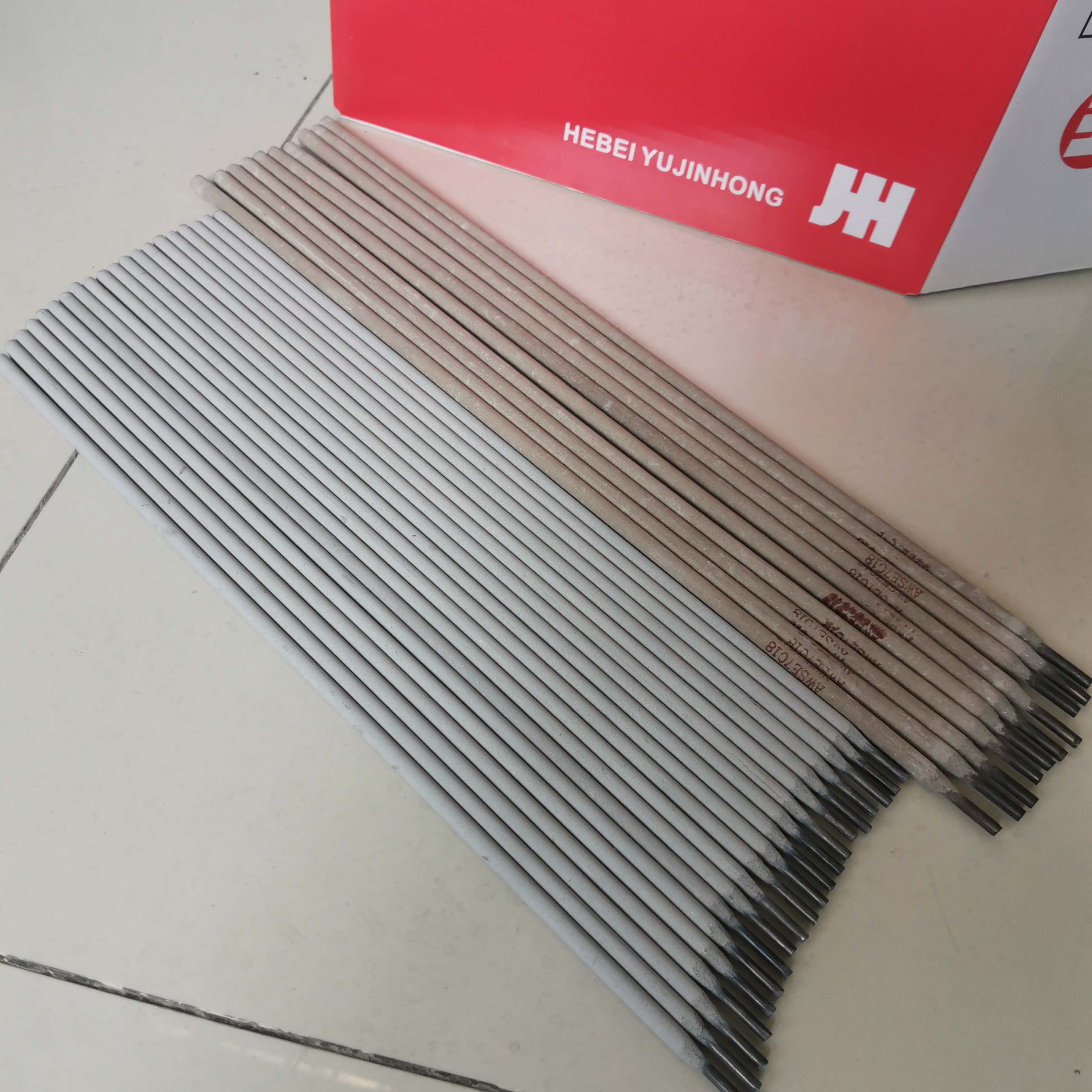

Model name: Pipeline welding rod E6010 cellulose welding rod (AWS E6010). Designed for carbon steel pipe butt welding and open-root work. Deep penetration, fast-freeze slag, runs best on DCEP.

| Classification | AWS A5.1 E6010 | Coating | High cellulose sodium |

| Polarity | DCEP (DC+) | Positions | All, including 5G/6G |

| Diameters | 2.5 / 3.2 / 4.0 / 5.0 mm (≈ 3/32–3/16") | UTS | ≈ 430–480 MPa (62–70 ksi), real-world may vary |

| Elongation | ≈ 22–28% | Diffusible H | Typically higher than low-hydrogen rods (≈20–30 ml/100g) |

| Storage | Dry, unopened; avoid high-temp re-bake | Shelf life | ≈ 12 months unopened (site conditions affect) |

How it’s made and qualified

Wire drawing, cellulose-sodium flux mixing, extrusion, and controlled baking (lower than low-hydrogen rods to preserve decomposition gases) create that aggressive, digging arc. Typical QA includes AWS A5.1 classification tests, bend tests, and procedure qualification under ASME IX or API 1104. For project lots, I’ve seen NDT acceptance per API 1104—RT/UT on root and hot pass—and occasional macro-etches. A sample report on one batch I reviewed: UTS 446 MPa, yield 350 MPa, El 26%, face/side bends acceptable at 180°, RT: no relevant indications.

Where it shines

- Cross-country oil and gas lines, station piping, gathering systems

- Open-root butt welds on carbon steel pipe (API 5L Grade B–X52, etc.)

- Repair welds where mill scale and minor moisture are realities

Pros: deep penetration, fast-freeze puddle, easy tie-ins. Cons: more spatter than low-hy types; hydrogen control relies on procedure, not the rod. Many customers say the arc starts “snappy,” which is what you want when you’re hanging iron on a windy ridge.

Vendor snapshot (quick compare)

| Vendor | Strengths | Certs/Docs | MOQ | Lead Time |

|---|---|---|---|---|

| SteelToolsChina (origin: Shijiazhuang) | High volume; stable supply; private-label options | Mill certs; AWS A5.1 conformity | Around 1–2 pallets | ≈ 2–4 weeks, project-dependent |

| Global Brand A | Extensive distributor network | Third-party test packs | 1 pallet+ | 2–6 weeks |

| Regional OEM B | Aggressive pricing | Basic COAs | Flexible | 1–3 weeks |

Notes: real-world terms vary by season, project size, and lane capacity.

Customization, process flow, and service

Custom options I’ve seen accepted: diameter mixes per crew preference, carton branding, moisture-resistant packaging, and WPS-driven lot testing (bend/RT witness). Typical flow: inquiry → WPS/standard alignment (API 1104, ASME IX) → sample lot → site trial → main lot with mill certs → logistics to yard. Shelf life ≈ 12 months if unopened; for opened boxes, keep dry and avoid high-temp re-bake (cellulose coatings don’t like it).

A quick case note

On a 24-inch product line, crews ran pipeline welding electrodes for open-root, then hot pass, followed by low-hydrogen fill/cap. With a 3.2 mm E6010 at 85–95 A DCEP, keyholes were stable, sidewalls wet-in clean, RT acceptance >95% on first pass. Not perfect weather, either—gusty. The fast-freeze puddle saved the day, to be honest.

Standards and acceptance

- AWS A5.1 classification for E6010

- WPS/PQR to ASME Section IX or API 1104

- Visual per AWS D1.1 fundamentals (where applicable)

- NDT: RT/UT acceptance per API 1104 project spec

Bottom line: if your spec calls for pipeline welding electrodes with aggressive root penetration and reliable tie-ins, E6010 is still the pragmatic pick. Just align procedures, storage, and inspection, and you’ll avoid the usual headaches.

Authoritative citations

- AWS A5.1/A5.1M: Specification for Carbon Steel Electrodes for Shielded Metal Arc Welding (American Welding Society)

- API Standard 1104: Welding of Pipelines and Related Facilities (American Petroleum Institute)

- ASME Boiler & Pressure Vessel Code, Section IX: Welding and Brazing Qualifications (ASME)

- ISO 2560-A: Covered electrodes for manual metal arc welding of non-alloy and fine grain steels (ISO)

- AWS D1.1/D1.1M: Structural Welding Code — Steel (AWS), inspection fundamentals often referenced

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025