High-Performance Carbon Rods for Welding | Strong, Clean Welds

Current Landscape and Industry Trends in Welding Electrodes

The global welding consumables market is experiencing robust growth, driven by expansion in manufacturing, infrastructure development, and the energy sector. Within this dynamic environment, the demand for reliable and high-performance carbon rods for welding, particularly those designed for carbon steel, remains consistently high. Industry trends indicate a strong push towards solutions that offer enhanced productivity, improved weld quality, and greater operational efficiency. There's an increasing emphasis on electrodes that provide superior arc stability, minimal spatter, and easy slag removal, directly contributing to reduced post-welding cleanup and faster project completion times.

Technological advancements are also shaping the market, with a focus on specialized coatings and formulations that enable welding in challenging positions and improve mechanical properties of the weld metal. Environmental considerations are likewise gaining traction, leading to the development of electrodes with lower fume emissions and more energy-efficient deposition processes. As industries like petrochemical, power generation, and construction continue to evolve, the requirement for versatile and robust carbon steel welding electrodes that meet stringent international standards becomes paramount.

Moreover, the integration of automation and robotic welding systems necessitates consumables with consistent performance characteristics, making the selection of high-quality carbon steel welding rod a critical factor for optimal system uptime and weld integrity. The market is also seeing a diversification in electrode sizes and packaging to cater to a broader range of applications, from intricate repair jobs to heavy fabrication projects, underscoring the adaptability required from manufacturers.

Manufacturing Process of Carbon Steel Welding Electrodes

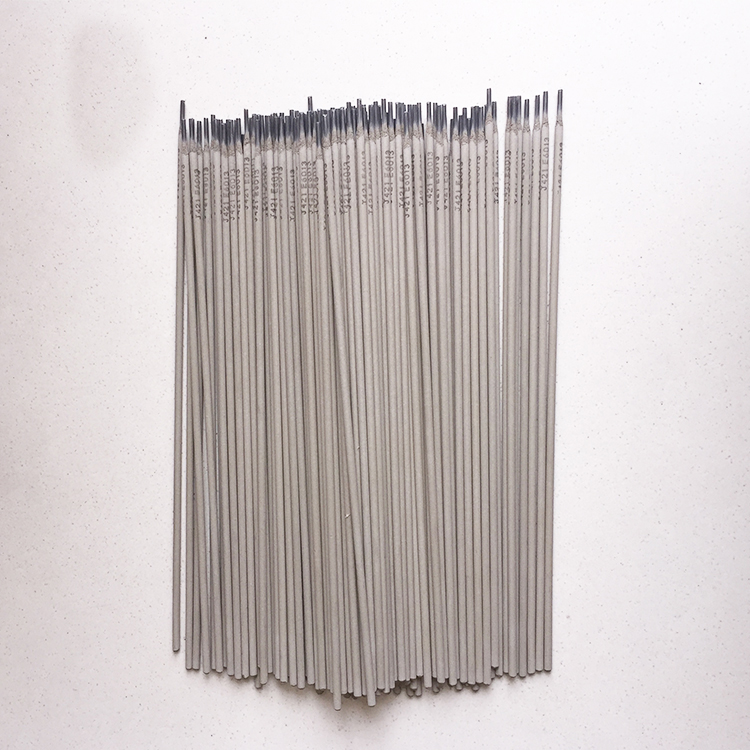

The production of high-quality carbon rods for welding involves a precise, multi-stage manufacturing process designed to ensure consistent performance, durability, and compliance with industry standards. Unlike traditional metal fabrication components that might undergo casting, forging, or CNC machining, welding electrodes are primarily manufactured through extrusion and specialized coating techniques.

Process Flow Overview:

1. Core Wire Preparation

High-grade steel wire, typically low carbon steel for E6013, is precision drawn to specified diameters (e.g., 2.5mm, 3.2mm, 4.0mm). It undergoes thorough cleaning to remove lubricants, rust, and scale, followed by straightening and cutting into exact lengths. This ensures a pristine base for coating adhesion.

2. Flux Formulation & Mixing

The flux coating is a complex mixture of mineral powders (e.g., cellulose, rutile, carbonates, silicates), alloying elements, and binders (e.g., sodium silicate, potassium silicate). Each component is precisely weighed and dry-mixed before being combined with liquid binders to form a consistent, plastic dough. This formulation dictates the electrode's welding characteristics and weld metal properties.

3. Extrusion Coating

The prepared core wires are fed into an extrusion press. The flux dough is extruded around the core wire under high pressure, forming a concentric and uniform coating. This critical step determines the electrode's dimensional accuracy and consistency.

4. Baking & Drying

Newly coated electrodes are transported through precisely controlled baking ovens. This process removes moisture from the flux coating, hardens it, and develops the required metallurgical properties. Temperature and duration are critical to prevent cracking and ensure optimal moisture content, which is vital for preventing hydrogen embrittlement during welding.

5. Tip Cleaning & Inspection

After baking, the arc striking end of each electrode is cleaned to expose the bare core wire for proper electrical contact. A rigorous inspection process follows, checking for coating defects, eccentricity, and dimensional accuracy. Samples are also taken for destructive testing.

6. Packaging & Labeling

Finished electrodes are packaged in moisture-resistant materials (e.g., vacuum-sealed foil bags, cardboard boxes with desiccant) to maintain their optimal condition. Each package is clearly labeled with product specifications, batch numbers, and compliance information, adhering to standards like ISO 2560 and AWS A5.1.

Quality Control & Standards:

All phases of manufacturing are subject to strict quality control, including material input inspection, in-process monitoring, and final product testing. Our products comply with international standards such as ISO 2560:2009 for covered electrodes for manual metal arc welding of non-alloy and fine grain steels, and AWS A5.1/A5.1M:2017 for specification for carbon steel electrodes for shielded metal arc welding. These standards ensure the electrodes meet specific mechanical properties, chemical composition of the weld metal, and usability characteristics.

Service Life & Target Industries:

The effective service life of an electrode (before welding) is significantly extended by proper storage conditions. Our electrodes, like the E6013, are designed for optimal performance in a range of demanding environments. Key target industries include petrochemical (pipelines, storage tanks), metallurgy (structural steel fabrication, heavy machinery), shipbuilding, construction, and water supply & drainage systems. Their versatility makes them ideal for general fabrication, light structural work, and repair welding of carbon steels.

In these applications, our electrodes demonstrate significant advantages such as energy saving through efficient deposition rates and minimal rework, and enhanced corrosion resistance in the weld metal due to controlled alloying elements and minimal porosity, contributing to the longevity of welded structures. For instance, in a large-scale pipeline project, the consistent performance and ease of use of our carbon steel welding electrodes can reduce welding time by up to 15%, leading to substantial energy and labor cost savings.

Technical Specifications: E6013 Welding Electrode Rods

The E6013 electrode is a mild steel, all-position, rutile-based electrode known for its smooth arc, excellent bead appearance, and easy slag removal. It's a highly versatile choice for general fabrication and repair work on mild steel. Below are detailed technical specifications, including typical mechanical properties of the weld metal and chemical composition, which underscore its reliability and performance.

Product Specification Table: E6013 Welding Electrode Rods for Carbon Steel

| Parameter | Typical Value / Standard | Description |

|---|---|---|

| AWS Classification | E6013 | Electrode for mild steel, all positions, AC/DC. |

| Tensile Strength (min) | 60 ksi (410 MPa) | Strength required to break the weld metal. |

| Yield Strength (min) | 48 ksi (330 MPa) | Stress at which the weld metal begins to deform plastically. |

| Elongation (min) | 22% | Ductility of the weld metal. |

| Impact Toughness (Charpy V-notch) | Not specified by AWS for E6013 (typical: 20J @ 0°C) | Resistance to brittle fracture. |

| Chemical Composition of Weld Metal (Typical %) | C: 0.08%, Mn: 0.45%, Si: 0.25%, S: 0.02%, P: 0.02% | Key elements influencing mechanical properties and usability. |

| Welding Positions | All (Flat, Horizontal, Vertical Up/Down, Overhead) | Versatility for various fabrication needs. |

| Welding Current | AC or DC Electrode Positive/Negative | Compatibility with most welding power sources. |

| Slag Removability | Easy | Reduces post-weld cleaning time. |

| Bead Appearance | Smooth, Fine Ripple | Aesthetically pleasing welds with good wetting. |

These specifications ensure that E6013 carbon rods for welding provide a reliable solution for various carbon steel applications, delivering consistent mechanical properties and excellent weldability. The precise control over chemical composition and manufacturing processes ensures that each carbon steel welding electrode performs as expected under a range of operating conditions, contributing to structural integrity and operational longevity.

Application Scenarios and Technical Advantages

The versatility and robust performance of carbon rods for welding, particularly the E6013 type, make them indispensable across a multitude of industries and applications involving carbon steel. Their unique technical characteristics translate into significant operational advantages for B2B stakeholders.

Key Application Scenarios:

- General Fabrication: Ideal for light to medium structural steel fabrication, frames, sheet metal work, and ornamental iron. The smooth arc and minimal spatter of carbon steel welding electrode simplify operations.

- Construction: Used in various construction projects for welding components of buildings, bridges, and other infrastructure where mild steel is prevalent.

- Automotive Repairs: Suitable for repair work on automotive components and agricultural equipment due to its easy use and good gap-bridging capabilities.

- Pipelines & Tanks: For low-pressure piping systems and storage tanks where robust, aesthetically pleasing welds are required without extensive joint preparation.

- Maintenance & Repair: Excellent for general workshop repairs, maintenance of machinery, and joining thin sections of carbon steel where precise control is beneficial.

Technical Advantages:

- Superior Arc Stability: E6013 electrodes offer a very stable arc, making them easy to strike and maintain, even for less experienced welders. This contributes to consistent weld quality and reduced operator fatigue.

- Excellent Bead Appearance: The rutile-based coating provides a smooth, fine-rippled bead with good wetting action, resulting in visually appealing welds that often require minimal grinding or finishing.

- Easy Slag Removal: The self-peeling or easily removable slag significantly reduces post-weld cleaning time and labor costs, boosting overall productivity.

- All-Position Capability: Its ability to weld in all positions (flat, horizontal, vertical up/down, overhead) offers unparalleled flexibility for fabricators and installers working on complex geometries or in restricted spaces.

- AC/DC Compatibility: Can be used with both AC and DC welding power sources, providing flexibility and compatibility with a wide range of welding equipment.

- Good Gap Bridging: Effective at bridging gaps in poorly fitted joints, which can be a significant advantage in repair work or where fit-up is less than ideal, minimizing rework.

- Energy Saving: The efficient deposition rate and reduced need for rework inherent in using quality carbon sticks for welding contribute to lower power consumption per welded joint and optimized operational costs.

- Corrosion Resistance: While primarily for mild steel, the weld metal typically exhibits good corrosion resistance for general atmospheric conditions due to controlled chemical composition and minimal porosity.

These advantages collectively position E6013 carbon rods for welding as a preferred choice for achieving high-quality, efficient, and cost-effective welds in numerous industrial and commercial settings.

Vendor Comparison and Customized Solutions

Selecting the right vendor for carbon rods for welding is a critical decision that impacts project timelines, weld quality, and overall operational costs. While specific vendor names are less important than the criteria for selection, understanding the differentiating factors is key for B2B buyers.

Key Differentiators in Welding Electrode Vendors:

| Criteria | High-Performing Vendor Attributes | Typical Vendor Attributes |

|---|---|---|

| Quality Certifications | ISO 9001:2015, AWS A5.1, CE, TUV, LR, DNV; rigorous internal QA/QC. | Basic compliance with national standards; limited third-party certifications. |

| Product Consistency | Batch-to-batch uniformity in arc stability, slag removal, and weld properties through advanced manufacturing and testing. | Variations in performance across different batches, leading to potential rework. |

| Technical Support & R&D | Dedicated application engineers, R&D for new formulations, problem-solving, and process optimization assistance. | Basic product data sheets; limited expert support. |

| Supply Chain & Logistics | Reliable global distribution, flexible ordering, responsive lead times, robust packaging against moisture. | Inconsistent delivery, limited stock, standard packaging prone to damage. |

| Customization Capability | Ability to tailor electrode formulations, sizes, or packaging for unique project requirements or environmental conditions. | Standardized product lines only; no flexibility. |

Customized Solutions for Welding Electrodes:

Recognizing that standard products may not always meet specialized project demands, reputable manufacturers offer tailored solutions for carbon steel welding electrode requirements. This customization can involve several aspects:

- Specialized Formulations: Adjusting the flux chemistry to optimize specific properties such as enhanced corrosion resistance in marine environments, improved impact toughness at low temperatures, or specific alloying for unique base metal compositions.

- Non-Standard Sizes & Lengths: Producing electrodes in diameters or lengths not typically found in standard catalogs, catering to unique automated welding setups or highly specialized manual applications.

- Packaging Solutions: Custom bulk packaging for high-volume users, specialized moisture-barrier packaging for extreme climates, or private-label branding for distribution partners.

- Compliance & Certification: Facilitating additional third-party certifications for specific projects or geographic regions, beyond standard AWS/ISO requirements, ensuring global applicability.

- Technical Advisory: Collaborating with clients' engineering teams to develop a welding procedure specification (WPS) that integrates a customized carbon sticks for welding solution, ensuring optimal weld performance and project compliance.

Engaging with a vendor capable of providing these tailored solutions ensures that complex welding challenges are met with precise and effective consumable designs, leading to superior results and maximized return on investment.

Application Case Studies and Customer Feedback

Real-world application demonstrates the true value and performance of carbon rods for welding. Our E6013 carbon steel welding rods have been instrumental in numerous projects across various demanding sectors, yielding consistent quality and efficiency. These case studies highlight the practical advantages and the trust placed in our products by industry leaders.

Case Study 1: Structural Steel Fabrication for a Commercial Complex

Challenge: A large construction firm required efficient and reliable welding consumables for fabricating a complex steel framework for a new commercial building. The project involved numerous joints in various positions and demanded high-quality welds with minimal post-welding cleanup to meet tight deadlines.

Solution: We supplied E6013 carbon steel welding electrodes in multiple diameters. Their all-position capability and smooth arc allowed welders to maintain high deposition rates even in overhead and vertical-up positions. The easily removable slag significantly reduced the time spent on grinding and cleaning.

Outcome: The project team reported a 12% increase in overall welding productivity and a noticeable reduction in consumable waste due to the consistent performance of the electrodes. The structural integrity and aesthetic appearance of the welds surpassed inspection standards. "The consistency of these carbon sticks for welding made a significant difference in our project timeline and quality control," commented the lead fabricator.

Case Study 2: Maintenance and Repair in a Petrochemical Plant

Challenge: A major petrochemical facility required routine maintenance and emergency repair welding on carbon steel pipelines and storage tanks. These applications often involved difficult access, varying material thicknesses, and the need for quick, robust repairs to minimize downtime.

Solution: Our E6013 electrodes were selected for their ease of use with both AC and DC machines, excellent re-strike capability, and reliable performance on marginally prepared surfaces. Their suitability for multiple welding positions was crucial in tight spaces typical of plant environments.

Outcome: The plant's maintenance team successfully completed several critical repairs, reporting strong, defect-free welds that easily passed NDT (Non-Destructive Testing). The quick slag removal and minimal spatter also contributed to faster turnaround times for emergency repairs. "For critical repairs, the reliability of these carbon steel welding rods is unparalleled. They get the job done right, the first time," stated the plant's welding supervisor.

Customer Feedback Highlights:

- "The E6013 electrodes provided by [Company Name] consistently deliver clean, strong welds with almost no spatter, saving us hours in cleanup." - Procurement Manager, Heavy Equipment Manufacturer.

- "We appreciate the uniform coating and excellent arc stability, which allows our welders to maintain high quality even during extended shifts." - Operations Director, Shipyard.

- "Their technical support helped us optimize our welding parameters for a challenging project. The carbon rods for welding performed flawlessly." - Chief Engineer, Infrastructure Development Co.

These testimonials and case studies reflect our commitment to providing high-performance carbon steel welding electrodes that meet and exceed industry expectations, fostering long-term partnerships built on trust and reliability.

Authoritativeness and Trustworthiness

Our commitment to excellence is deeply rooted in adherence to stringent quality standards, robust certifications, and transparent operational practices. We understand that for B2B partners, trust is built on verifiable credentials and unwavering support.

Certifications and Compliance:

- ISO 9001:2015 Certified: Our manufacturing facilities and quality management systems are certified to ISO 9001:2015, ensuring consistent product quality and continuous improvement in our processes.

- AWS A5.1/A5.1M: All our E6013 carbon rods for welding fully comply with the American Welding Society's standards for carbon steel electrodes for shielded metal arc welding.

- CE Mark: Our products meet the health, safety, and environmental protection standards for products sold within the European Economic Area.

- Additional Classifications: Depending on product lines, we hold approvals from leading classification societies such as Lloyd's Register (LR) and DNV GL, further validating the performance of our carbon steel welding rod in critical applications.

Frequently Asked Questions (FAQ):

Q: What is the recommended storage for E6013 electrodes?

A: E6013 electrodes should be stored in a dry environment at room temperature, ideally in original sealed packaging, to prevent moisture absorption. For opened packages, store in a heated oven at 70-100°C (150-210°F) to ensure optimal performance, though E6013 is generally more tolerant to moisture than low-hydrogen electrodes.

Q: Can E6013 be used for welding high-strength carbon steel?

A: E6013 is primarily designed for mild carbon steels (tensile strength up to 480 MPa). For high-strength carbon steels, different classifications like E7018 or other low-hydrogen electrodes are recommended to match mechanical properties and minimize the risk of hydrogen-induced cracking.

Q: What is your typical lead time for large orders of carbon sticks for welding?

A: Standard lead time for large orders is typically 3-4 weeks, depending on the specific product and quantity. We maintain significant inventory for common sizes to expedite smaller or urgent orders. Please contact our sales team for precise lead time estimates for your specific requirements.

Lead Time and Fulfillment:

We pride ourselves on efficient logistics and a robust supply chain. Our average lead time for standard products ranges from 2-4 weeks, with expedited options available for critical projects. We employ advanced inventory management systems to ensure product availability and timely dispatch globally. Our packaging is designed for optimal protection during transit, maintaining product integrity upon arrival.

Warranty and Customer Support:

All our carbon rods for welding are backed by a comprehensive warranty against manufacturing defects. We guarantee that our products meet or exceed their stated specifications when stored and used according to industry best practices. Our dedicated customer support team and technical service engineers are available to assist with product selection, application guidance, troubleshooting, and post-sales inquiries. We aim to ensure complete satisfaction and uninterrupted operations for our clients.

For immediate assistance, please visit our website at www.steeltoolschina.com or contact our support hotline.

References

- AWS A5.1/A5.1M:2017. Specification for Carbon Steel Electrodes for Shielded Metal Arc Welding. American Welding Society.

- ISO 2560:2009. Welding consumables – Covered electrodes for manual metal arc welding of non-alloy and fine grain steels – Classification. International Organization for Standardization.

- The Fabricator. Trends in Welding Consumables. FMA Communications, Inc. (General industry overview, not a specific article)

- Lincoln Electric. E6013 Welding Electrode Product Data. (General product information)

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025