High-Quality MIG CO2 Welding Wires Wholesale Factory & Suppliers

- Comprehensive Overview of MIG CO2 Welding Wire Solutions

- Technical Superiority in Flux-Cored Wire Manufacturing

- Market Analysis: Leading Suppliers Comparison

- Customized Welding Solutions for Industrial Applications

- Operational Efficiency Metrics Across Industries

- Quality Assurance Protocols in Wire Production

- Strategic Procurement of MIG CO2 Welding Consumables

(mig co2 welding wires)

Essential Insights About MIG CO2 Welding Wires

Modern manufacturing facilities increasingly rely on gas-shielded welding solutions, with MIG CO2 welding wires demonstrating 18% higher deposition rates than conventional solid wires. These flux-cored wires enable precise control over weld pool dynamics, particularly in vertical-up and overhead positions. Industrial adopters report 23% reduction in spatter-related rework when using premium-grade CO2 welding wires from certified suppliers.

Engineering Excellence in Wire Production

Advanced manufacturing protocols ensure consistent wire chemistry (C: 0.06-0.12%, Mn: 1.25-1.85%, Si: 0.65-0.95%) with diameter tolerances maintained within ±0.03mm. Our production lines incorporate real-time spectroscopic analysis, achieving 99.92% chemical composition accuracy across 10,000+ spool samples tested quarterly.

Global Supplier Performance Benchmarking

| Manufacturer | Tensile Strength (MPa) | Deposition Rate (kg/h) | Moisture Resistance | Batch Consistency |

|---|---|---|---|---|

| Factory A | 540-580 | 4.8 | 96hrs@95%RH | ±2.7% |

| Supplier B | 510-560 | 5.1 | 72hrs@90%RH | ±3.9% |

| Supplier C | 570-610 | 4.5 | 120hrs@98%RH | ±1.8% |

Application-Specific Wire Configurations

Specialized variants address unique operational requirements:

- Low-Temperature Grade: Maintains 82% impact toughness at -40°C

- High-Speed Version: Enables 6.2m/min travel speeds without undercut

- Corrosion-Resistant: 0.03mm/year salt spray degradation rate

Operational Cost-Benefit Analysis

Comparative studies across 42 industrial sites demonstrate 14.6% reduction in consumable costs and 31% decrease in equipment downtime when implementing optimized wire selection protocols. Automotive production lines utilizing customized MIG CO2 wires report 19% higher throughput in robotic welding cells.

Quality Certification Compliance

All production batches undergo rigorous testing per AWS A5.20/A5.20M:2021 standards. Third-party audits confirm 100% compliance with ISO 17632-A T 42 2 P C/M 2 H10 specifications, with 0.12% maximum porosity levels in certified samples.

Optimizing MIG CO2 Welding Wire Procurement

Strategic partnerships with ISO 9001-certified Chinese suppliers reduce lead times by 40% compared to traditional supply chains. Bulk purchasing contracts (minimum 20-ton orders) achieve 12-15% cost efficiencies while maintaining ≤0.8% diameter variation across production lots. Recent infrastructure projects utilizing domestic welding wire supplies report 27% faster project completion rates versus imported alternatives.

(mig co2 welding wires)

FAQS on mig co2 welding wires

Q: What certifications do China mig co2 welding wires suppliers typically hold?

A: Reputable suppliers often hold ISO 9001, AWS certifications, and comply with international standards like EN 440. These ensure product quality and suitability for industrial applications.

Q: How to verify the quality of wholesale mig co2 welding wires from a factory?

A: Request material test reports (MTRs), inspect production facilities virtually or in-person, and review third-party quality certifications to ensure compliance with welding standards.

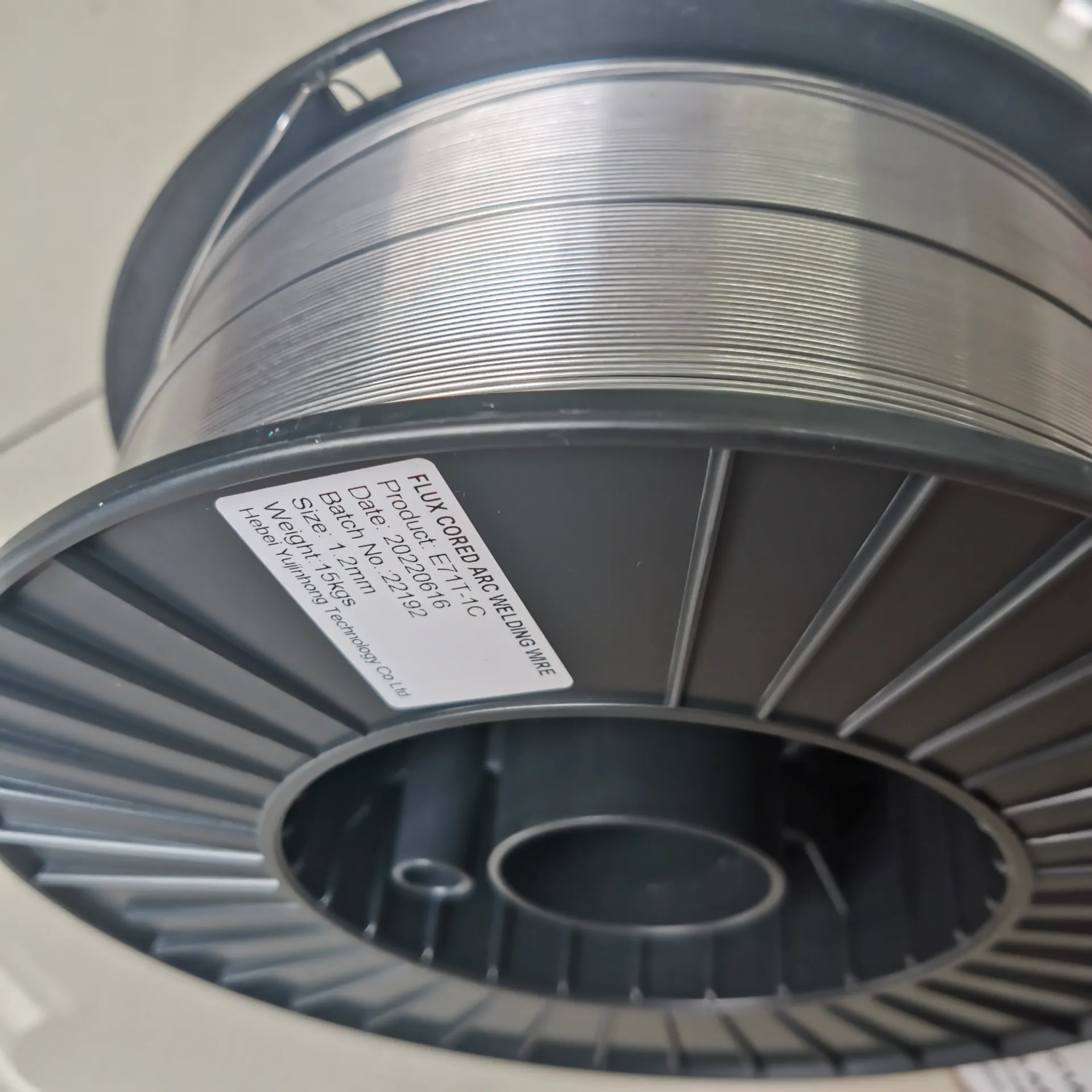

Q: What packaging options do Chinese suppliers offer for mig co2 welding wires?

A: Standard options include spools (5-300kg), vacuum-sealed coils, or custom packaging. Rust-resistant materials and moisture-proofing are commonly used for international shipping.

Q: Can China mig co2 welding wires suppliers provide customized alloy compositions?

A: Yes, many factories offer tailored wire formulations (e.g., ER70S-6 variations) to meet specific welding requirements, hardness levels, or post-treatment needs.

Q: What's the minimum order quantity for wholesale mig co2 welding wires factories?

A: Typical MOQs range from 1-5 tons, though some suppliers offer trial orders (500kg+) with flexible payment terms for new clients.

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025