Leading Manufacturer of 0.030% Welding Wire for Superior Performance and Quality

Understanding the Importance of 0.030% Welding Wire Manufacturers

Welding is an integral part of modern manufacturing and construction, serving as the backbone for bonding metals in various industries including automotive, aerospace, and structural fabrication. Among the myriad of welding materials available, 0.030% welding wire is particularly noteworthy due to its unique attributes that cater to specific applications. This article explores the significance of 0.030% welding wire manufacturers in ensuring high-quality welding processes.

What is 0.030% Welding Wire?

The designation 0.030% typically refers to the diameter of the welding wire, which is around 0.030 inches or approximately 0.76 mm. This type of welding wire is often used in gas metal arc welding (GMAW), commonly known as MIG welding. The wire size is crucial as it influences the welding speed, heat input, and penetration characteristics during the welding process.

0.030% welding wire is exceptionally versatile and can be used for a variety of metals, including mild steel, stainless steel, and aluminum. Its size makes it ideal for welding thinner materials, ensuring clean welds with minimal distortion. Furthermore, it is compatible with different shielding gases, which can also be tailored to the specific type of welding and the properties desired in the finished product.

The Role of Manufacturers

Manufacturers of 0.030% welding wire play a critical role in the industry, as the quality and composition of the wire directly impact the integrity of the welds produced. High-quality welding wire manufacturers prioritize the use of premium materials and advanced production technologies. This commitment to quality ensures that the wire possesses the necessary mechanical properties, such as tensile strength and ductility, to withstand the demands of various welding applications.

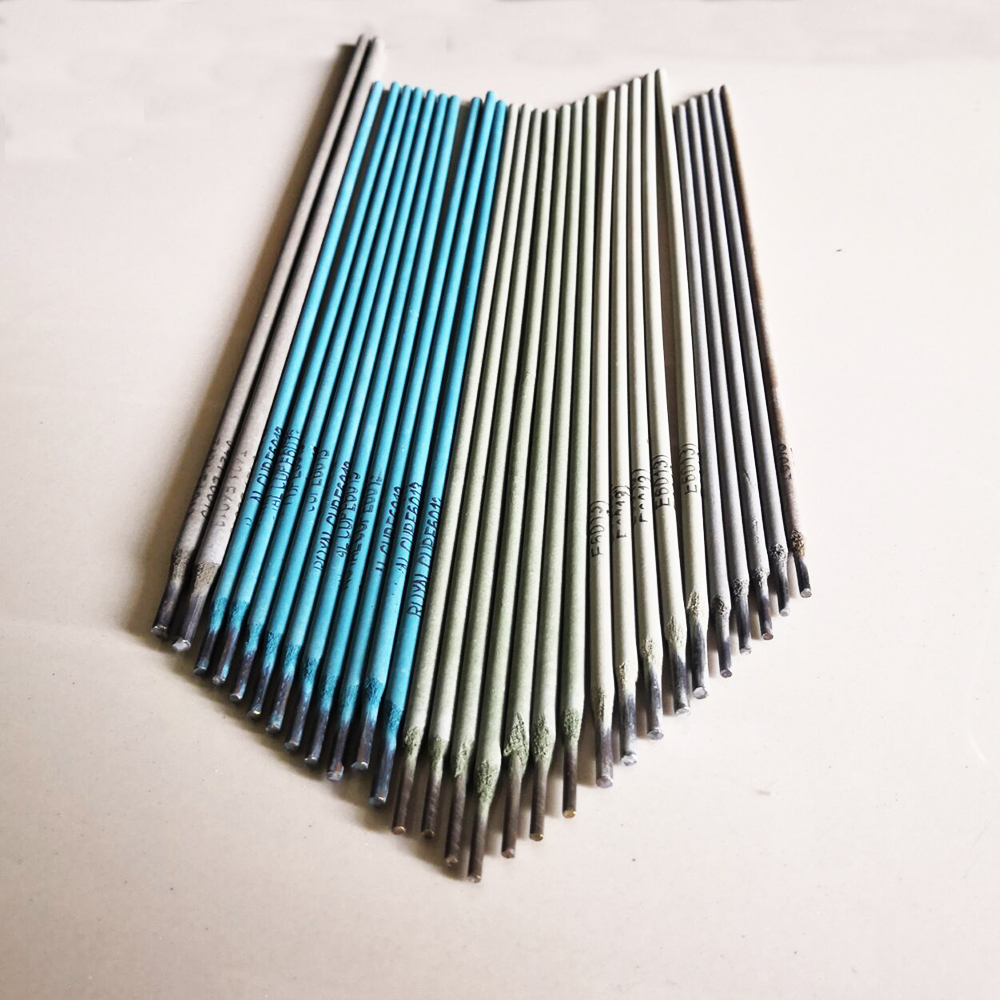

0.030 welding wire manufacturer

Moreover, reputable welding wire manufacturers adhere to strict standards and certifications, guaranteeing that their products meet both national and international quality benchmarks. This assures customers that they are investing in reliable materials for their projects, ultimately enhancing safety and performance.

Innovation in Welding Wire Production

In recent years, advancements in manufacturing processes and materials science have led to innovations in welding wire production. Modern manufacturers are increasingly focusing on developing welding wires that not only ensure optimal performance but also reduce environmental impact. For instance, some manufacturers are exploring eco-friendly materials and processes, which can decrease the carbon footprint of welding operations.

Additionally, with the rise of automation and digital technologies, manufacturers are adopting innovative approaches to streamline production and improve consistency. This, coupled with advancements in quality control, enables them to deliver high-performance welding wires with greater reliability.

Conclusion

In summary, 0.030% welding wire manufacturers are vital to the welding industry, providing essential materials that enable high-quality and efficient welding processes. Their commitment to quality, innovation, and sustainability not only enhances the performance of welding operations but also ensures the safety and integrity of critical structures across various sectors. As industries continue to evolve and embrace new technologies, the role of skilled manufacturers in producing exceptional welding wire remains indispensable. Investing in reliable welding wire will undoubtedly contribute to the success of any welding project, paving the way for superior outcomes and ensuring long-lasting results.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025