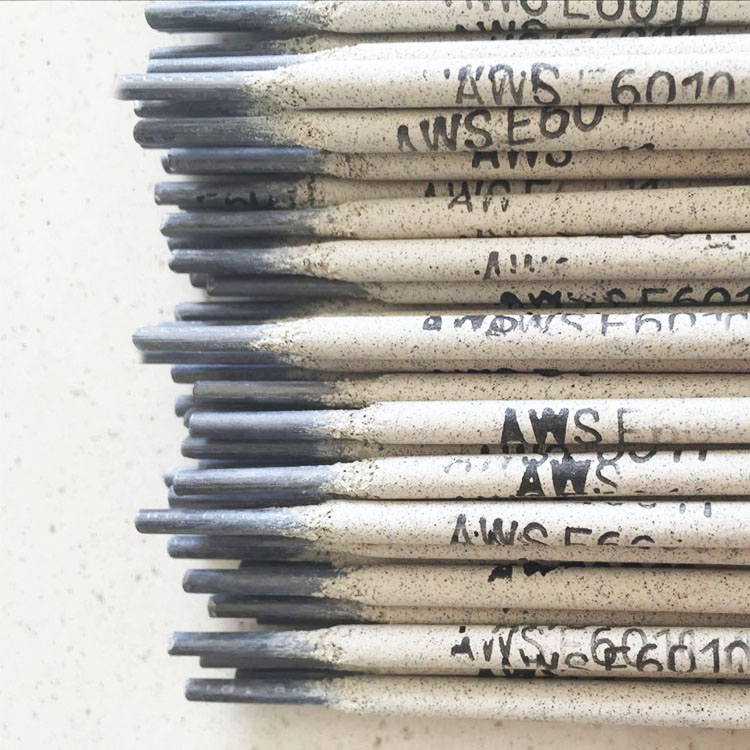

2.5mm welding electrodes 6013 factory

The Significance of 2.5mm Welding Electrodes E6013 in Modern Welding Practices

Welding is an essential process in various industries, ranging from construction to manufacturing. Among the many welding materials available, 2.5mm E6013 welding electrodes hold a significant place due to their versatility and efficiency. This article delves into the characteristics, applications, and advantages of E6013 welding electrodes, particularly in the 2.5mm size.

Understanding E6013 Welding Electrodes

The E6013 welding electrode is a type of mild steel electrode known for its excellent all-position welding capabilities. The E stands for electrode, 60 denotes a minimum tensile strength of 60,000 psi, and 1 indicates that it is suitable for all positions. The 3 in E6013 signifies the low hydrogen content and the type of coating used, which is typically a rutile-based coating. This coating contributes to the electrode's smooth operation and ease of use.

The Importance of the 2.5mm Size

The 2.5mm diameter of the E6013 electrode makes it particularly useful for various welding tasks. This size provides a balance between penetration and bead control, allowing welders to achieve desired results in different welding scenarios. The 2.5mm electrode is ideal for thinner materials, making it a go-to choice for automotive repair, metal fabrication, and other applications where precision is key.

Advantages of Using E6013 Electrodes

2.5mm welding electrodes 6013 factory

1. Versatility E6013 electrodes can be used for welding carbon steels, low alloy steels, and some stainless steels, making them versatile tools for welders. Their ability to perform across multiple positions—flat, horizontal, vertical, and overhead—further enhances their utility.

2. Ease of Use Welders, both beginners and experienced, find E6013 electrodes easy to work with. The smooth arc, stable welding characteristics, and minimal spatter contribute to a more manageable welding process. This ease of use is particularly beneficial for less experienced welders looking to develop their skills.

3. Clean Beads The rutile coating on E6013 electrodes results in clean, aesthetically pleasing welds with minimal cleanup required post-welding. This is a significant advantage in applications where appearance matters, such as decorative metalwork or in situations where the weld will be visible.

4. Low Hydrogen Content The E6013 electrodes' low hydrogen content minimizes the risk of hydrogen-induced cracking in welded joints, ensuring structural integrity and durability. This feature is particularly critical in pressure vessels or other high-stress applications where weld quality is paramount.

5. Wide Applications Due to their properties, 2.5mm E6013 electrodes are used in a variety of fields, including construction, automotive repair, manufacturing, and maintenance services. They are suitable for welding thin sheets, pipe repair, and even some heavier structural applications when using appropriate techniques.

Conclusion

The 2.5mm E6013 welding electrode stands as a vital tool in the arsenal of welders worldwide. Its blend of versatility, ease of use, and reliability makes it suitable for a wide array of applications. As industries continue to evolve and demand higher quality and efficiency from welding processes, the importance of reliable materials like the E6013 electrode cannot be overstated. Whether you are a hobbyist or a professional welder, understanding the advantages and applications of E6013 electrodes can enhance your welding skills and optimize your projects. The future of welding will undoubtedly continue to embrace such essential materials that facilitate innovation and quality in the field.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025