2.5mm Welding Rod Specifications and Applications for Efficient Metal Joining Techniques

Understanding 2.5mm Welding Rods A Comprehensive Guide

Welding is an essential manufacturing process used across various industries, from construction to automotive. One of the critical components that significantly affect the quality of welds is the welding rod. Among the many sizes available, the 2.5mm welding rod is particularly popular for its versatility and effectiveness in a range of applications. This article delves into the characteristics, uses, and advantages of 2.5mm welding rods, offering insights for both novice and seasoned welders.

Characteristics of 2.5mm Welding Rods

The diameter of a welding rod plays a crucial role in the welding process, influencing factors like penetration, heat input, and the overall strength of the weld. A 2.5mm welding rod is relatively small, making it suitable for thin materials and intricate welds. Typically made of mild steel or other alloys, these rods are coated with a flux that aids in the welding process by stabilizing the arc, protecting the weld pool from contamination, and facilitating the removal of slag post-welding.

The 2.5mm size is standard for many types of welding, particularly in the Stick (SMAW) and MIG processes. The choice of a 2.5mm rod is often related to the thickness of the materials being joined and the specific requirements of the welding task at hand.

Applications of 2.5mm Welding Rods

2.5mm welding rods are widely used in various applications

1. General Fabrication Their versatility makes them an excellent choice for general fabrication projects, including building frames, supports, and structures.

2. Repair Works For repairing thin metal components or structures, a 2.5mm rod provides the precision needed without excessive heat input, which can warp or damage the workpiece.

3. Automotive Industry In automotive maintenance and repair, these rods are used for welding bodywork and exhaust systems, where weld strength and aesthetics are important.

4. Pipe Welding Due to their smaller size, 2.5mm rods are often utilized for root passes in pipe welding, where precise control is necessary.

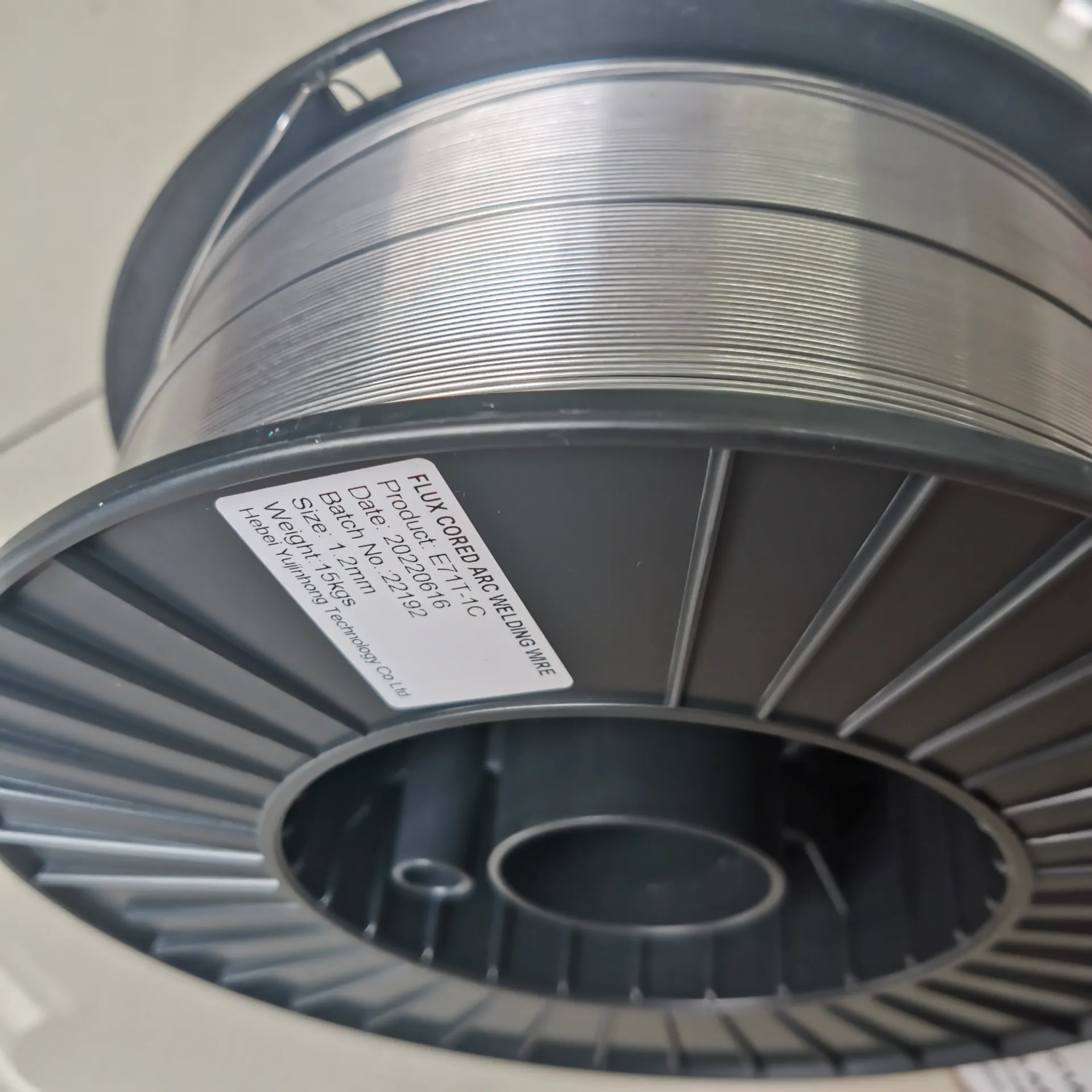

2.5mm welding rod

Advantages of 2.5mm Welding Rods

There are several advantages to using 2.5mm welding rods, which contribute to their popularity among welders

1. Precision The smaller diameter allows for enhanced control and precision, essential for detailed work and thin materials.

2. Less Heat Input A 2.5mm welding rod generates less heat compared to larger rods, reducing the risk of distortion and warping in the base metals.

3. Easier to Handle For welders, handling these smaller rods can be easier, especially in tight or awkward positions where greater maneuverability is necessary.

4. Cost-Effective Smaller rods are often more economical and allow for more efficient use of material, making them a cost-effective choice for hobbyists and professionals alike.

5. Weld Quality The use of a 2.5mm welding rod can result in high-quality welds that require minimal finishing, due to the cleaner arc and efficient slag removal.

Conclusion

Selecting the right welding rod is vital for achieving optimal results in welding projects. The 2.5mm welding rod stands out as a versatile and effective option suitable for various tasks across multiple industries. Its characteristics make it particularly advantageous for precision work, repairs, and applications requiring lower heat input.

For anyone involved in welding, whether as a profession or a hobby, understanding the nuances of different welding rods, including the 2.5mm variety, can significantly impact the quality of their work. As technology and techniques continue to evolve in the welding industry, the role of suitable materials like 2.5mm welding rods remains crucial for achieving flawless welds that stand the test of time. Whether you're a seasoned professional or just starting your welding journey, incorporating 2.5mm welding rods into your toolkit could enhance your capabilities and the quality of your welds.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025