3. Reliable Factory-Produced 1.2mm Flux-Cored Welding Wire Suitable for CO2 Welding Projects

Understanding Flux-Cored Welding Wire 1.2mm CO2 Factory Applications

Flux-cored welding has become an essential technique in the welding industry, providing versatility and efficiency for various applications. One of the most prevalent forms of flux-cored wire is the 1.2mm CO2 welding wire, which is favored in manufacturing environments, especially those requiring robust and reliable welds. This article explores the characteristics, advantages, and applications of 1.2mm CO2 flux-cored welding wire, particularly in factory settings.

What is Flux-Cored Welding Wire?

Flux-cored welding wire is a type of electric arc welding process where a continuously fed wire is used to create a robust weld. Unlike traditional welding rods, flux-cored wire is filled with a powdered flux that serves multiple purposes—shielding the weld from atmospheric contamination, stabilizing the arc, and aiding in the formation of a clean, strong weld. The 1.2mm diameter is particularly noteworthy as it strikes a balance between penetration and heat input, making it ideal for various thicknesses of metal.

Characteristics of 1.2mm CO2 Flux-Cored Wire

1. Size and Feedability The 1.2mm diameter ensures good feedability in semi-automatic and automatic welding systems. Its size allows it to navigate through welding guns without causing jams or irregular feeding, which is crucial in high-volume production environments.

2. CO2 Shielding Using CO2 as a shielding gas helps protect the molten weld pool from contamination and oxidation. This is particularly advantageous in outdoor or less controlled environments where wind or other factors can introduce impurities.

3. Versatile Applications 1.2mm flux-cored wire is adept at welding various materials, including mild steel and stainless steel. This versatility makes it a go-to choice for many industries, such as automotive manufacturing, construction, shipbuilding, and heavy machinery.

Advantages of Using Flux-Cored Welding Wire

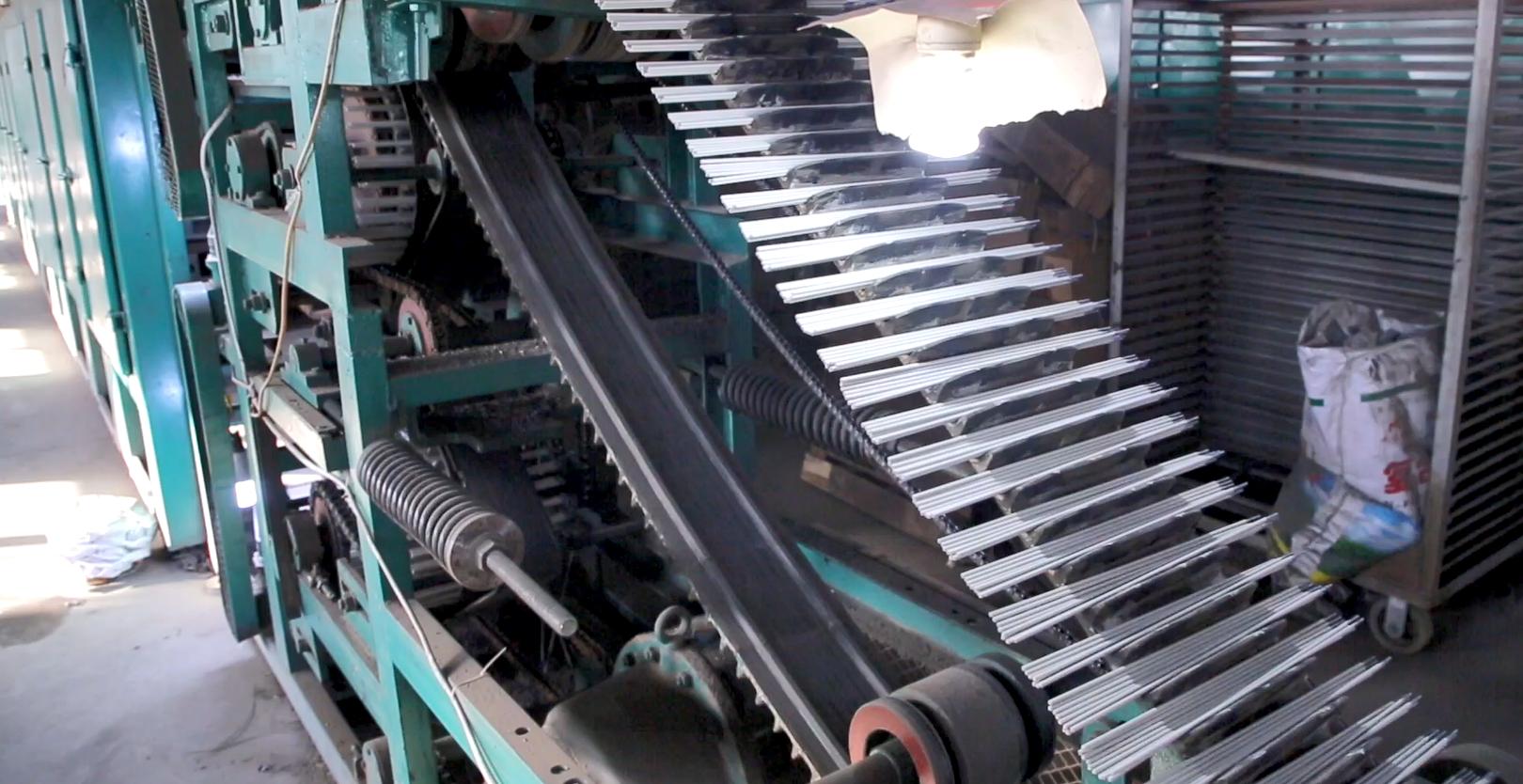

flux cored welding wire 1.2mm co2 factory

1. Higher Deposition Rates Compared to traditional stick welding, flux-cored welding offers higher deposition rates, meaning that more weld metal is deposited in less time. This efficiency is particularly valuable in a factory environment where speed and productivity are paramount.

2. All-Position Welding Flux-cored wires allow for all-position welding, enabling operators to perform overhead, vertical, and flat welds with relative ease. This flexibility is essential in complex structures where orientation may vary.

3. Less Cleanup The slag produced during flux-cored welding is easier to remove compared to other processes. This results in less downtime for cleanup and preparation, allowing for a seamless workflow on the factory floor.

4. Improved Weld Quality The CO2 shielding gas used with flux-cored welding provides a protective layer over the weld area, which contributes to better mechanical properties in the finished weld, such as strength and toughness.

Applications in Factories

In manufacturing settings, 1.2mm CO2 flux-cored welding wire is primarily used for fabricating metal components and structures. It is ideal for making critical joints in machinery, creating frames for vehicles, and assembling parts in large-scale productions. Additionally, as industries push for more automated welding solutions, the use of flux-cored wire in robotic applications is on the rise, marrying the benefits of automation with the robustness of flux-cored welding.

Conclusion

Overall, the 1.2mm CO2 flux-cored welding wire stands out as a vital tool in modern manufacturing processes. Its ability to produce high-quality welds quickly and efficiently makes it ideal for factories aiming to enhance productivity without compromising on weld integrity. As industries continue to evolve, the demand for such reliable welding solutions will only increase, solidifying the role of flux-cored welding wire in the future of manufacturing.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025