Jan . 31, 2025 02:54

Back to list

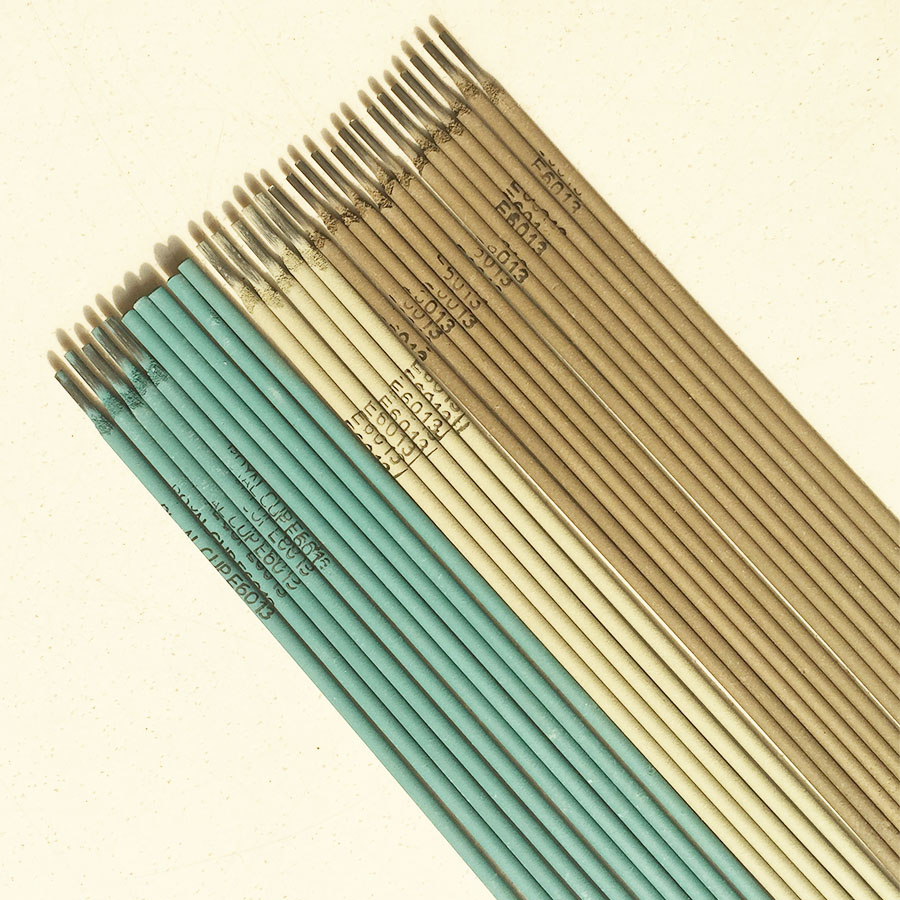

carbon steel welding rod

The 308 16 welding rod is a critical tool in the arsenal of both amateur and professional welders, specifically designed for welding austenitic stainless steels, particularly grade 304 and 304L. Understanding the nuances of this product can significantly impact the quality of your welding projects, ensuring durable and aesthetically pleasing results.

Trustworthiness in using the 308 16 welding rod is underscored by the widespread adoption of these rods in critical fields such as pharmaceuticals and architecture. Welders and project managers consistently rely on this product for its predictable behavior and reliable outcomes. It's an industry staple because of its proven record in environments where failure is not an option. Real-life experiences from professional welders highlight the rod's ease of use and adaptability. For those new to welding or transitioning to stainless steel projects, the 308 16 provides a smoother learning curve thanks to its forgiving nature on thinner gauge materials and its compatibility with various stainless steel compositions. Veterans, on the other hand, appreciate its consistency and how it supports precise, clean welding lines without warping or deforming the pieces. Using the 308 16 welding rod also translates into cost-efficiencies. By reducing the likelihood of weld failures and the associated costs of reworks or repairs, businesses can protect their bottom line while maintaining the integrity of their infrastructure. In strategic contexts, leveraging the strengths of the 308 16 can open opportunities for expanding service offerings. This could mean branching out into new types of steel fabrication projects or offering enhanced warranties that reflect the confidence in the quality achievable with this tool. In conclusion, the 308 16 welding rod is more than just a tool for melding metals. It embodies a blend of innovation, precision, and reliability that meets the exacting demands of modern industries. For those embracing the art and science of welding, investing in high-quality rods like the 308 16 is an investment in skill, reputation, and the enduring strength of the structures they build.

Trustworthiness in using the 308 16 welding rod is underscored by the widespread adoption of these rods in critical fields such as pharmaceuticals and architecture. Welders and project managers consistently rely on this product for its predictable behavior and reliable outcomes. It's an industry staple because of its proven record in environments where failure is not an option. Real-life experiences from professional welders highlight the rod's ease of use and adaptability. For those new to welding or transitioning to stainless steel projects, the 308 16 provides a smoother learning curve thanks to its forgiving nature on thinner gauge materials and its compatibility with various stainless steel compositions. Veterans, on the other hand, appreciate its consistency and how it supports precise, clean welding lines without warping or deforming the pieces. Using the 308 16 welding rod also translates into cost-efficiencies. By reducing the likelihood of weld failures and the associated costs of reworks or repairs, businesses can protect their bottom line while maintaining the integrity of their infrastructure. In strategic contexts, leveraging the strengths of the 308 16 can open opportunities for expanding service offerings. This could mean branching out into new types of steel fabrication projects or offering enhanced warranties that reflect the confidence in the quality achievable with this tool. In conclusion, the 308 16 welding rod is more than just a tool for melding metals. It embodies a blend of innovation, precision, and reliability that meets the exacting demands of modern industries. For those embracing the art and science of welding, investing in high-quality rods like the 308 16 is an investment in skill, reputation, and the enduring strength of the structures they build.

Previous:

Next:

Latest news

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025