309 welding electrode manufacturers

The Landscape of 309 Welding Electrode Manufacturers

Welding is a critical process in various industries, from construction to automotive, and it requires specialized materials to ensure effective and lasting joins. Among the essential materials in welding is the electrode, and 309 welding electrodes have carved out a significant niche due to their unique properties. These electrodes are particularly favored for their ability to weld dissimilar metals, especially stainless steels to mild steels, making them indispensable in a range of applications.

Understanding 309 Welding Electrodes

309 welding electrodes are designed to provide a robust and durable weld when joining different types of metals. Composed primarily of chromium (23%) and nickel (13%), these electrodes exhibit excellent resistance to oxidation and corrosion. This makes them ideal for high-temperature applications where standard electrodes might fail. They are commonly used in industries such as food processing, chemical processing, and oil and gas, where the integrity of welded joints is crucial in harsh environments.

The Role of Manufacturers

The growing demand for 309 welding electrodes has led to the emergence of numerous manufacturers worldwide. These manufacturers play a vital role in ensuring that high-quality electrodes are accessible to stakeholders in various industries. They are responsible for the production, quality control, and supply chain management of welding electrodes, ensuring that they meet industry standards and specifications.

Several key factors differentiate successful 309 welding electrode manufacturers from less effective ones

1. Quality Assurance Leading manufacturers employ stringent quality control measures throughout the production process. This includes material selection, manufacturing techniques, and final product testing to ensure that the electrodes perform as expected under intense conditions.

309 welding electrode manufacturers

2. Technological Innovation The best manufacturers invest in modern technology and research to enhance the properties of their electrodes. This includes refining the chemical composition, improving the coating materials, and developing new manufacturing processes that increase efficiency and performance.

3. Customization Different welding jobs may require specific properties from electrodes. Top manufacturers provide customized solutions tailored to the unique needs of their clients, offering a range of diameters and coatings suitable for various welding techniques.

4. Certification and Compliance Reputable manufacturers ensure their products comply with international standards and certifications, such as AWS (American Welding Society) and ISO (International Organization for Standardization). This compliance assures clients of the reliability and safety of the welding electrodes.

5. Sustainability Practices With growing environmental concerns, many manufacturers are adopting sustainable practices in their operations. This includes using eco-friendly materials, minimizing waste during production, and ensuring that their products can be recycled.

Major Players in the Market

Several established companies are recognized as leaders in the manufacturing of 309 welding electrodes. Companies like Lincoln Electric, ESAB, and Miller Electric have a global footprint and are known for their innovative products and commitment to quality. These manufacturers not only produce welding electrodes but also provide training and support to welders, ensuring that their clients can maximize the use of their products.

Conclusion

The market for 309 welding electrodes continues to expand as industries demand more robust and versatile materials. Manufacturers play a crucial role in meeting this demand, ensuring that high-quality electrodes are available for various applications. As technology advances and sustainability becomes a focal point, the future of welding electrode manufacturing looks promising. Engaging with reputable manufacturers can ensure that businesses focus on efficiency, safety, and the quality of their welding operations. Understanding the qualities that make a great 309 welding electrode manufacturer can significantly impact the success of welding projects across various sectors.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

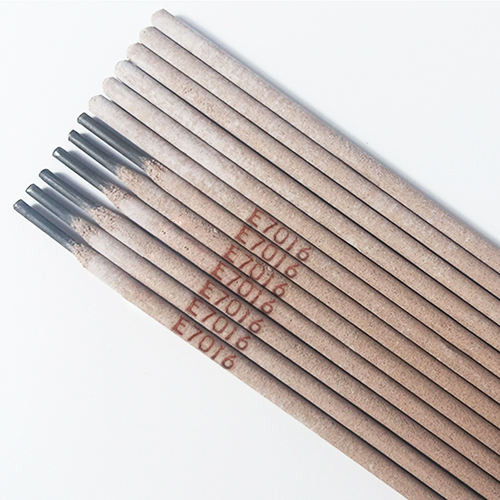

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025