Jun . 15, 2024 18:42

Back to list

316L stainless steel welding rod suppliers

316L-16% 20 Welding Rod Manufacturers Pioneering Quality and Innovation

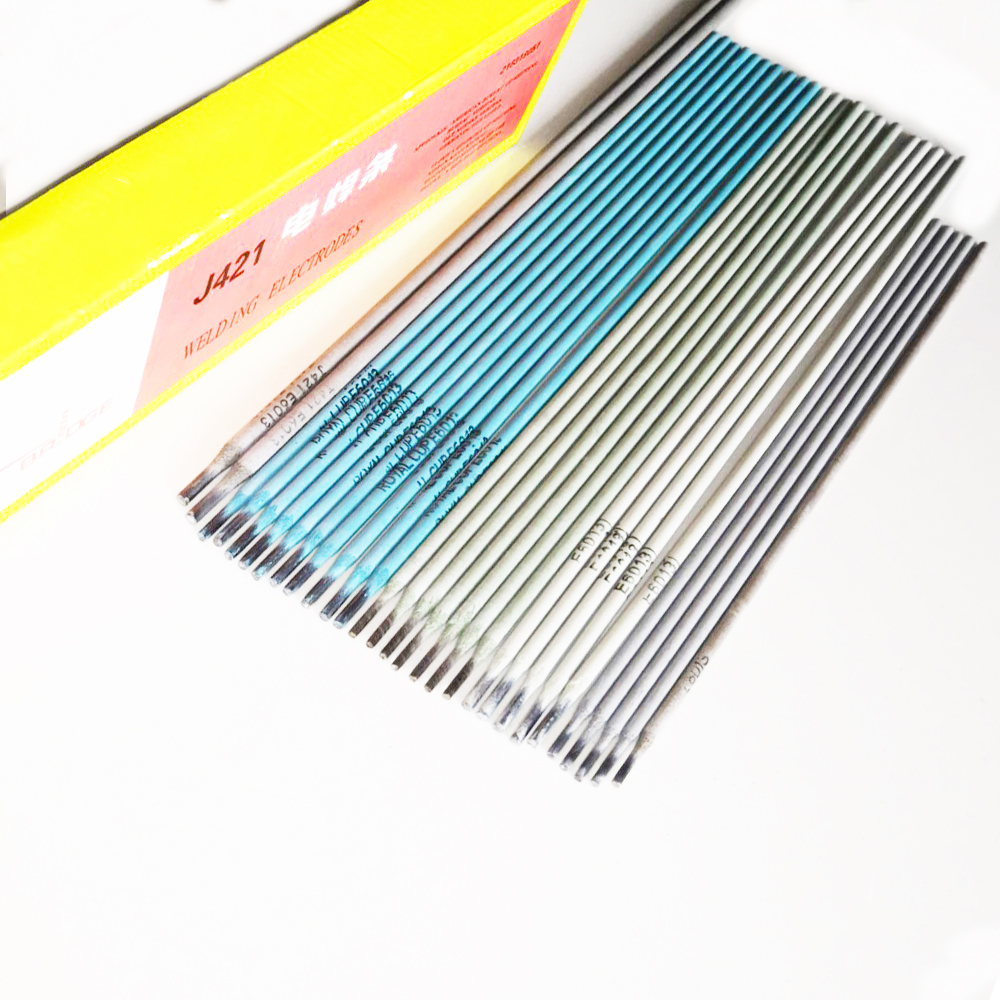

In the realm of welding materials, the demand for high-quality products is paramount. One such premium product is the 316L-16% 20 welding rod, a staple in industries where corrosion resistance and strength are crucial. This article highlights the pioneering efforts of manufacturers specializing in this type of welding rod, showcasing their commitment to excellence and innovation.

The 316L-16% 20 welding rod is composed of stainless steel with an increased molybdenum content, making it exceptionally resistant to chloride-induced corrosion. Its low carbon content ensures excellent weld penetration while minimizing the risk of intergranular corrosion after welding. These attributes make it ideal for marine applications, chemical processing, and any environment where robust corrosion resistance is needed.

Manufacturers of these specialized welding rods have invested heavily in research and development to optimize their products' performance. They understand that the success of a welding project often hinges on the quality of the materials used. Thus, they employ rigorous quality control measures throughout the production process, from sourcing raw materials to the final packaging.

One key area of innovation has been in the development of coatings for the welding rods. Advanced coating technologies protect the rod from contamination and moisture during storage and use, extending its shelf life and ensuring consistent performance weld after weld. Some manufacturers have also introduced coatings that reduce spatter during welding, improving efficiency and reducing the need for cleanup Some manufacturers have also introduced coatings that reduce spatter during welding, improving efficiency and reducing the need for cleanup Some manufacturers have also introduced coatings that reduce spatter during welding, improving efficiency and reducing the need for cleanup Some manufacturers have also introduced coatings that reduce spatter during welding, improving efficiency and reducing the need for cleanup

Some manufacturers have also introduced coatings that reduce spatter during welding, improving efficiency and reducing the need for cleanup Some manufacturers have also introduced coatings that reduce spatter during welding, improving efficiency and reducing the need for cleanup 316l-16 welding rod manufacturers.

Moreover, these manufacturers recognize the importance of environmental stewardship. They strive to minimize their ecological footprint by implementing sustainable manufacturing practices. This includes using recycled materials where possible and optimizing energy consumption in their facilities. By doing so, they not only contribute to conservation efforts but also lower production costs, allowing them to offer competitive pricing without sacrificing quality.

Customer education is another focus area for these manufacturers. They provide comprehensive guides and training materials to help users select the appropriate welding rod for their specific application. This educational outreach ensures that professionals can achieve the best results and maintain the high standards expected in their fields.

In conclusion, manufacturers of 316L-16% 20 welding rods stand at the forefront of quality and innovation. Their dedication to producing top-tier welding materials, combined with a commitment to sustainability and customer education, ensures that industry standards are met and often exceeded. As technology evolves and demands shift, these manufacturers are poised to continue leading the way in providing exceptional welding solutions for today's challenging environments.

316l-16 welding rod manufacturers.

Moreover, these manufacturers recognize the importance of environmental stewardship. They strive to minimize their ecological footprint by implementing sustainable manufacturing practices. This includes using recycled materials where possible and optimizing energy consumption in their facilities. By doing so, they not only contribute to conservation efforts but also lower production costs, allowing them to offer competitive pricing without sacrificing quality.

Customer education is another focus area for these manufacturers. They provide comprehensive guides and training materials to help users select the appropriate welding rod for their specific application. This educational outreach ensures that professionals can achieve the best results and maintain the high standards expected in their fields.

In conclusion, manufacturers of 316L-16% 20 welding rods stand at the forefront of quality and innovation. Their dedication to producing top-tier welding materials, combined with a commitment to sustainability and customer education, ensures that industry standards are met and often exceeded. As technology evolves and demands shift, these manufacturers are poised to continue leading the way in providing exceptional welding solutions for today's challenging environments.

Some manufacturers have also introduced coatings that reduce spatter during welding, improving efficiency and reducing the need for cleanup Some manufacturers have also introduced coatings that reduce spatter during welding, improving efficiency and reducing the need for cleanup

Some manufacturers have also introduced coatings that reduce spatter during welding, improving efficiency and reducing the need for cleanup Some manufacturers have also introduced coatings that reduce spatter during welding, improving efficiency and reducing the need for cleanup 316l-16 welding rod manufacturers.

Moreover, these manufacturers recognize the importance of environmental stewardship. They strive to minimize their ecological footprint by implementing sustainable manufacturing practices. This includes using recycled materials where possible and optimizing energy consumption in their facilities. By doing so, they not only contribute to conservation efforts but also lower production costs, allowing them to offer competitive pricing without sacrificing quality.

Customer education is another focus area for these manufacturers. They provide comprehensive guides and training materials to help users select the appropriate welding rod for their specific application. This educational outreach ensures that professionals can achieve the best results and maintain the high standards expected in their fields.

In conclusion, manufacturers of 316L-16% 20 welding rods stand at the forefront of quality and innovation. Their dedication to producing top-tier welding materials, combined with a commitment to sustainability and customer education, ensures that industry standards are met and often exceeded. As technology evolves and demands shift, these manufacturers are poised to continue leading the way in providing exceptional welding solutions for today's challenging environments.

316l-16 welding rod manufacturers.

Moreover, these manufacturers recognize the importance of environmental stewardship. They strive to minimize their ecological footprint by implementing sustainable manufacturing practices. This includes using recycled materials where possible and optimizing energy consumption in their facilities. By doing so, they not only contribute to conservation efforts but also lower production costs, allowing them to offer competitive pricing without sacrificing quality.

Customer education is another focus area for these manufacturers. They provide comprehensive guides and training materials to help users select the appropriate welding rod for their specific application. This educational outreach ensures that professionals can achieve the best results and maintain the high standards expected in their fields.

In conclusion, manufacturers of 316L-16% 20 welding rods stand at the forefront of quality and innovation. Their dedication to producing top-tier welding materials, combined with a commitment to sustainability and customer education, ensures that industry standards are met and often exceeded. As technology evolves and demands shift, these manufacturers are poised to continue leading the way in providing exceptional welding solutions for today's challenging environments. Previous:

Latest news

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025