3 32 7018 welding rod factories

The Role of 3 32 7018 Welding Rod Factories in Modern Manufacturing

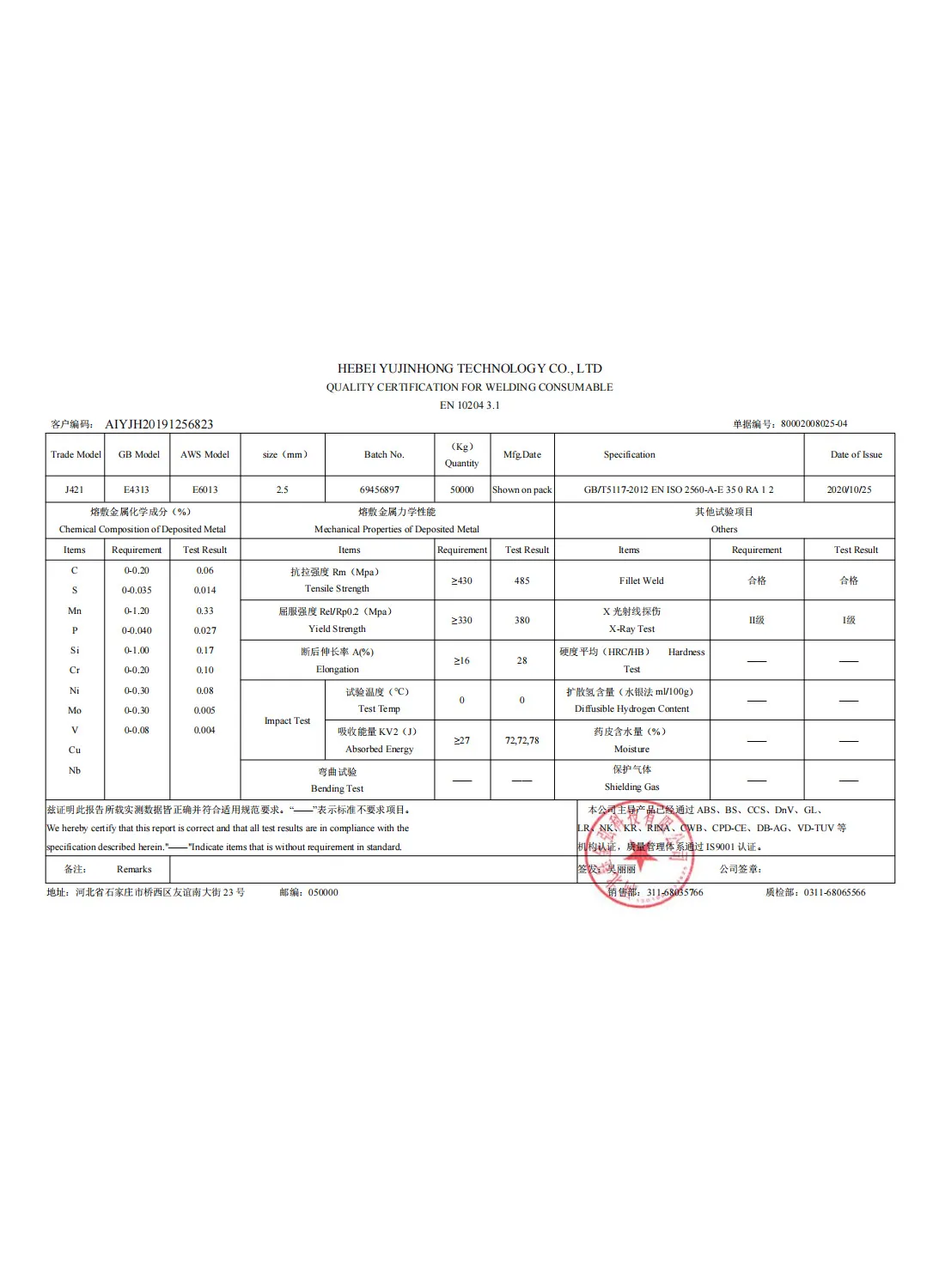

In the world of manufacturing and construction, the importance of quality welding rods cannot be underestimated. Among these, 3 32 7018 welding rods have gained significant recognition for their versatile applications and superior performance. These rods are integral in various welding processes, including shielded metal arc welding (SMAW), and are often preferred for their mechanical properties and ease of use.

The Role of 3 32 7018 Welding Rod Factories in Modern Manufacturing

The unique composition of 3 32 7018 welding rods, which typically includes a well-balanced mix of alloys, provides excellent metallurgical properties. This composition results in a welding rod that offers good arc stability, minimal spatter, and impressive bead appearance. As a result, welders can achieve stronger and more reliable welds, which is critical in applications where structural integrity is paramount.

3 32 7018 welding rod factories

Moreover, the versatility of 3 32 7018 welding rods makes them suitable for various welding positions, whether it be flat, horizontal, vertical, or overhead. This adaptability allows factories to utilize these rods in diverse projects, from building bridges to manufacturing heavy machinery. The ability to handle different welding positions without compromising on quality makes 3 32 7018 rods a go-to choice for many professionals.

In recent years, the demand for these welding rods has surged, driven by the growth of the construction and manufacturing sectors globally. As a result, welding rod factories have ramped up production to meet this increasing demand. The competitive landscape in welding materials has led to innovations in manufacturing techniques, including automated processes and improved supply chain logistics, enabling these factories to deliver products more efficiently.

Sustainability is also becoming a key focus in the production of 3 32 7018 welding rods. Many factories are exploring environmentally friendly practices, such as utilizing recycled materials and reducing waste in their production processes. This shift not only helps in conserving resources but also aligns with the industry's evolving standards for environmental responsibility.

In conclusion, 3 32 7018 welding rod factories are essential players in the manufacturing landscape. By producing high-quality welding rods that meet diverse industrial needs, these factories contribute significantly to the safety, durability, and efficiency of welded structures. As technology advances and industry demands evolve, these factories will continue to adapt, ensuring that they remain at the forefront of welding innovation.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025