Jan . 29, 2025 00:51

Back to list

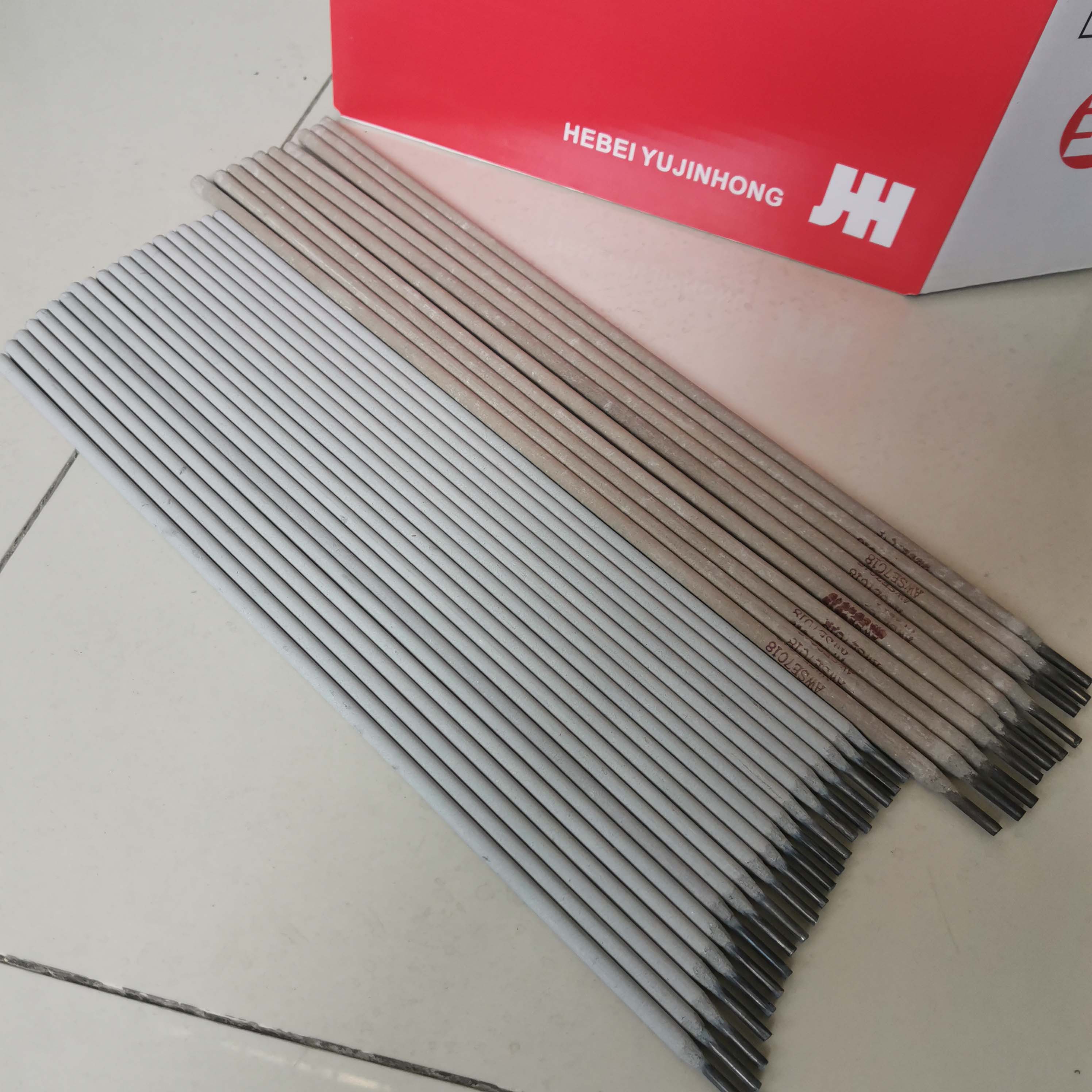

50 lbs 7018 welding rod

When it comes to welding, few things are as crucial as selecting the right welding rod. Among the vast array of options available, the 50 lbs 7018 welding rod stands out as a favorite among welding professionals and hobbyists alike. This article delves deep into understanding the unique attributes, applications, and advantages that make the 7018 rod an essential part of any welder's toolkit.

The 7018 is particularly effective when the weld requires high-impact strength and flexibility. Its effectiveness in dealing with dynamic stresses makes it invaluable in applications such as shipbuilding, where the structure must endure constant movement and harsh conditions. Similarly, its application in bridge construction ensures the stability and safety of these critical structures over long periods. Seasoned welders often recommend proper storage of 7018 rods to maintain their effectiveness. The rods must be kept dry, ideally in a rod oven at temperatures ranging between 250-300 degrees Fahrenheit, to prevent the absorption of moisture. This ensures the retention of low-hydrogen properties, critical for achieving the structural integrity expected of 7018 welds. From an expertise standpoint, understanding the nuances of the 7018 welding rod can significantly enhance a welder's craftsmanship. Selecting the appropriate current settings, maintaining optimal rod angles, and controlling travel speeds are all skills that can maximize the advantages of these rods, leading to superior weld quality. For those new to welding with 7018, expert advice and practice are key to mastering its use. In summary, the 50 lbs 7018 welding rod is more than just a consumable in the welder’s arsenal; it is a cornerstone of robust and reliable welding. Its blend of strength, reliability, and ease-of-use positions it as a preferred choice among professionals aiming to achieve high-quality, durable welds in demanding applications. By prioritizing proper usage and handling, welders can fully harness the potential of 7018 rods, ensuring that their welding work meets the highest standards of quality and safety.

The 7018 is particularly effective when the weld requires high-impact strength and flexibility. Its effectiveness in dealing with dynamic stresses makes it invaluable in applications such as shipbuilding, where the structure must endure constant movement and harsh conditions. Similarly, its application in bridge construction ensures the stability and safety of these critical structures over long periods. Seasoned welders often recommend proper storage of 7018 rods to maintain their effectiveness. The rods must be kept dry, ideally in a rod oven at temperatures ranging between 250-300 degrees Fahrenheit, to prevent the absorption of moisture. This ensures the retention of low-hydrogen properties, critical for achieving the structural integrity expected of 7018 welds. From an expertise standpoint, understanding the nuances of the 7018 welding rod can significantly enhance a welder's craftsmanship. Selecting the appropriate current settings, maintaining optimal rod angles, and controlling travel speeds are all skills that can maximize the advantages of these rods, leading to superior weld quality. For those new to welding with 7018, expert advice and practice are key to mastering its use. In summary, the 50 lbs 7018 welding rod is more than just a consumable in the welder’s arsenal; it is a cornerstone of robust and reliable welding. Its blend of strength, reliability, and ease-of-use positions it as a preferred choice among professionals aiming to achieve high-quality, durable welds in demanding applications. By prioritizing proper usage and handling, welders can fully harness the potential of 7018 rods, ensuring that their welding work meets the highest standards of quality and safety.

Previous:

Latest news

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025