7018 electrodos suppliers

Understanding the Importance of 7018 Electrodes and Their Suppliers

Welding is a vital process in a variety of industries, and the quality of the welding materials used directly impacts the strength and durability of the welded structures. Among the many types of welding electrodes available, the 7018 electrode, a low hydrogen filler rod, stands out for its reliability and performance in various welding applications. This article will explore the significance of 7018 electrodes and the role of suppliers in ensuring quality materials reach welders.

Understanding the Importance of 7018 Electrodes and Their Suppliers

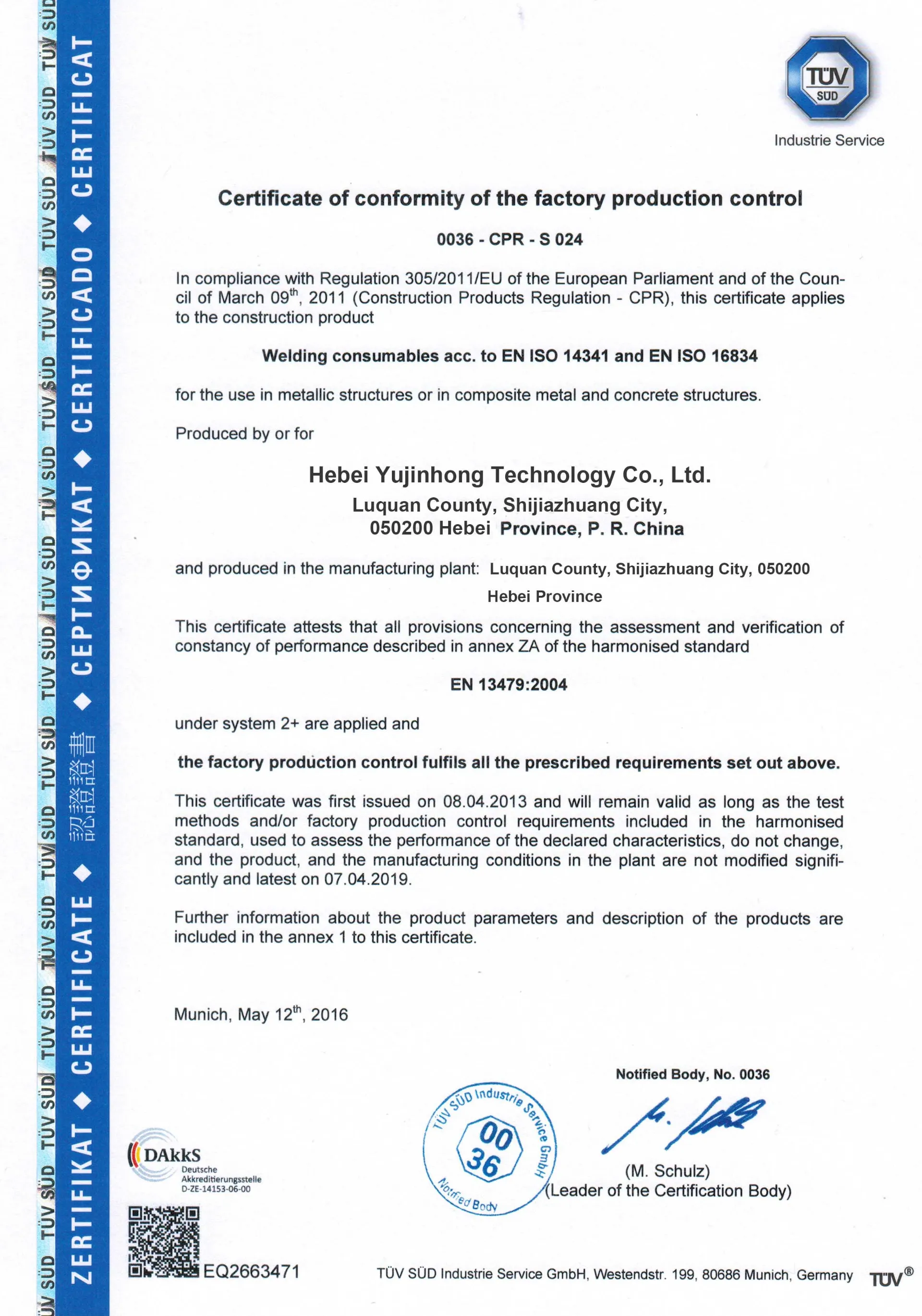

When it comes to procuring 7018 electrodes, the role of suppliers cannot be overstated. Quality suppliers are critical in providing welders with reliable and certified materials. The sourcing of these electrodes involves not only the production of superior quality welding rods but also the assurance that they meet international standards. Suppliers must adhere to guidelines set by organizations such as the American Welding Society (AWS) to guarantee that the 7018 electrodes perform effectively and safely in various applications.

7018 electrodos suppliers

Additionally, suppliers provide essential information regarding the storage and handling of 7018 electrodes, as improper storage can lead to moisture absorption, which can compromise the electrode’s performance. Professionals in the welding industry rely on suppliers not only for product availability but also for technical support and guidance. This relationship fosters a deeper understanding of the product and empowers welders to select the most suitable materials for their specific projects.

In recent years, the demand for 7018 electrodes has grown due to advancements in welding technology and an expanded scope of applications. As industries focus on constructing stronger and more durable structures, the need for quality welding materials has never been more crucial. Consequently, suppliers are continuously working to refine their processes, enhance product quality, and ensure sustainability in their operations.

In conclusion, the importance of 7018 electrodes in the welding industry cannot be overlooked. They provide essential strength and ductility in welded joints while minimizing the risk of defects. Reliable suppliers play a crucial role in this ecosystem, guaranteeing that welders have access to high-quality materials. By investing in reputable suppliers, industries can enhance their productivity and the performance of their welded structures, ultimately leading to safer and more resilient constructed environments. As the welding landscape evolves, the roles of both the electrodes and their suppliers will continue to be integral to technological advancements and industry standards.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025