Affordable Bulk MIG MAG Welding Wire Supply from Reliable Manufacturers for High-Quality Projects

Understanding Wholesale MIG/MAG Welding Wire Factories

In the world of industrial manufacturing, the importance of quality welding materials cannot be overstated. Among these materials, MIG (Metal Inert Gas) and MAG (Metal Active Gas) welding wires are essential for achieving strong, durable welds. Wholesale MIG/MAG welding wire factories play a pivotal role in supplying these critical materials to various sectors, including automotive, construction, and manufacturing.

What is MIG/MAG Welding?

MIG welding is a type of gas metal arc welding (GMAW) that uses a continuous feed of solid wire and an inert or semi-inert gas to protect the weld pool from contamination. The process is known for its speed and versatility, making it ideal for both thin and thick materials. MAG welding, on the other hand, employs active gases that may react with the molten weld pool, often providing enhanced penetration and weld quality.

These welding processes demand high-quality wires that can withstand rigorous applications. This is where wholesale factories come into play, supplying manufacturers with the necessary welding wires in bulk.

The Role of Wholesale Factories

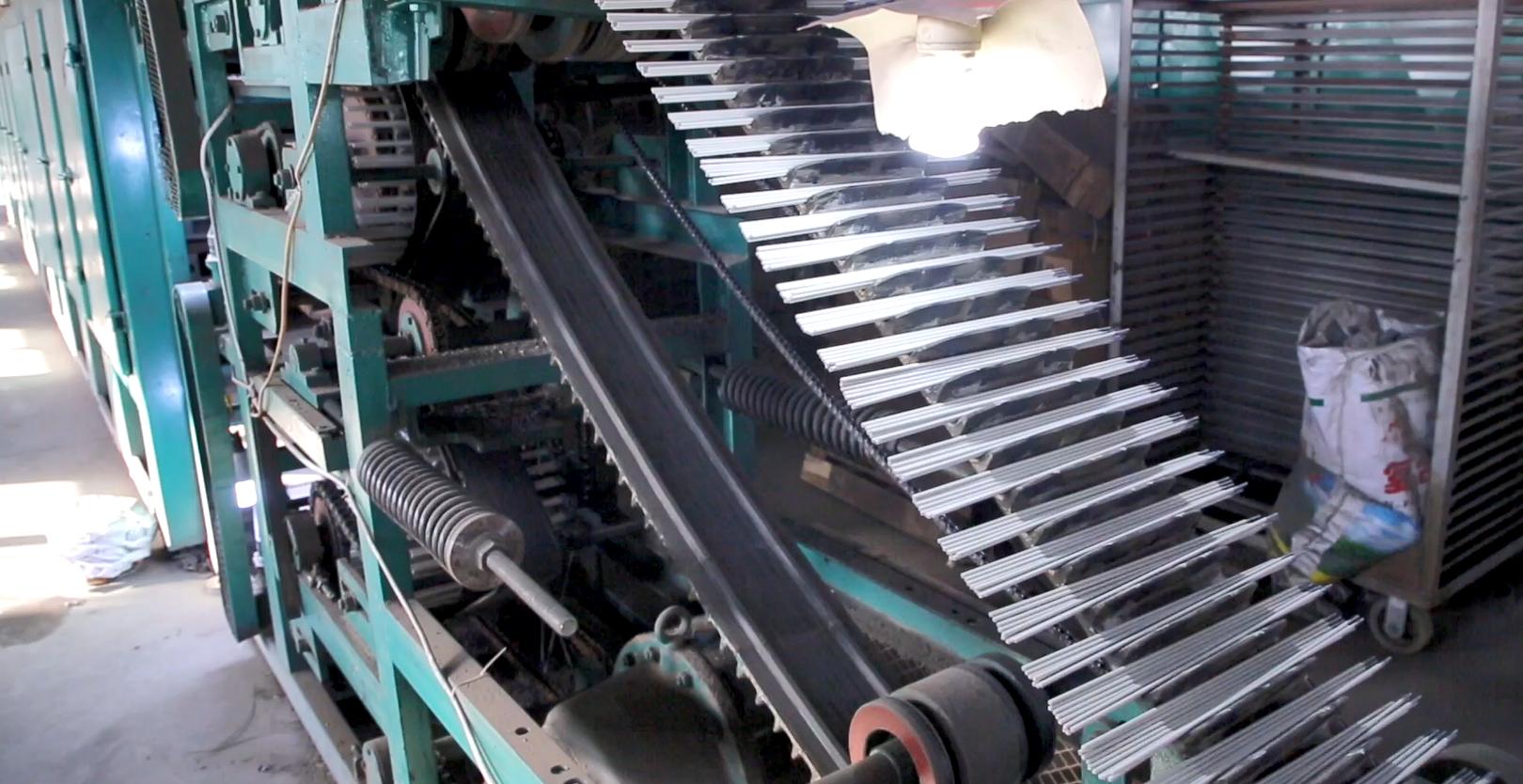

Wholesale MIG/MAG welding wire factories specialize in producing and distributing welding wires to meet industrial needs. They are equipped with advanced machinery that ensures the uniformity and consistency of the wires, which is essential for achieving optimal welding results. These factories usually produce wires of various diameters and compositions tailored to specific welding applications, such as carbon steel, stainless steel, and alloyed materials.

One of the main advantages of purchasing from wholesale manufacturers is cost-effectiveness. Bulk purchasing allows manufacturers to save significantly on material costs, which can be a crucial factor in maintaining profitability in a competitive market. Furthermore, direct relationships with factories can lead to better pricing, improved supply chain management, and reduced lead times for delivery.

wholesale mig mag welding wire factory

Quality Control Standards

To ensure that the welding wires meet the required specifications and performance standards, reputable wholesale MIG/MAG welding wire factories implement rigorous quality control measures. These include raw material inspection, in-process testing, and final product evaluation. Certifications such as ISO 9001 often indicate adherence to international quality standards, giving buyers confidence in the materials they are using.

Additionally, these factories often evolve with technological advancements, investing in research and development to produce wires that enhance welding efficiency and reduce spatter. They may also specialize in producing wires that perform well in specific environments or unique applications, like in high-temperature or corrosive settings.

Future Trends in Welding Wire Manufacturing

As the manufacturing industry continues to evolve, the demand for high-quality, durable welding wires will only increase. Factors such as the growth of automation in welding processes and the rising prevalence of environmentally-friendly practices necessitate the development of innovative welding materials.

Wholesale MIG/MAG welding wire factories are keen to invest in sustainable practices, adopting eco-friendly production methods that reduce waste and energy consumption. They are also exploring the use of advanced materials that can address modern challenges, such as lightweight alloys for the automotive industry or high-strength wires for construction applications.

Conclusion

Wholesale MIG/MAG welding wire factories are essential players in the manufacturing landscape, providing high-quality materials that empower various industries. By understanding the significance of these factories, businesses can make informed decisions when sourcing welding materials and thereby enhance their operational efficiency. As technology and industry standards continue to advance, the collaboration between manufacturers and wholesale suppliers will pave the way for innovation and growth in welding technologies.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025