Affordable Wholesale Welding Wire from Leading Chinese Manufacturers for Quality Industrial Solutions

Exploring the World of Wholesale China Welding Wire Factories

The welding industry is a critical sector, underpinning various other industries such as construction, automotive, and manufacturing. At the heart of this industry are welding wires, essential components used in various welding processes. With the rise of globalization, China has emerged as a dominant player in the production and supply of welding wires, thanks to a plethora of wholesale factories scattered across the country.

The Significance of Welding Wires

Welding wires serve as electrodes that provide the necessary material to complete the welding process. They come in various types, including solid wires, flux-cored wires, and stainless-steel wires, each designed for specific applications. The quality of welding wires directly impacts the integrity and durability of the weld, making it crucial for welders to select high-grade materials for their jobs.

Advantages of Sourcing From Chinese Factories

1. Cost-Effectiveness One of the primary advantages of sourcing welding wires from Chinese wholesale factories is cost savings. Thanks to lower labor costs and large-scale production capabilities, Chinese manufacturers can offer competitive prices without compromising quality. Businesses looking to reduce operational costs often find it beneficial to import welding wires from these factories.

2. Diverse Options China is home to numerous factories specializing in a variety of welding wires. This diversity allows buyers to find specific types of welding materials suited for different projects. Whether it's low carbon steel, stainless steel, or specialized alloys, Chinese manufacturers have an extensive range to choose from.

3. Technological Advancements Many Chinese welding wire factories have adopted modern manufacturing techniques and innovative technologies. This leads to improved product quality, consistency, and performance. Factories often invest in research and development to enhance their products, thus benefiting their clients who depend on high-quality materials.

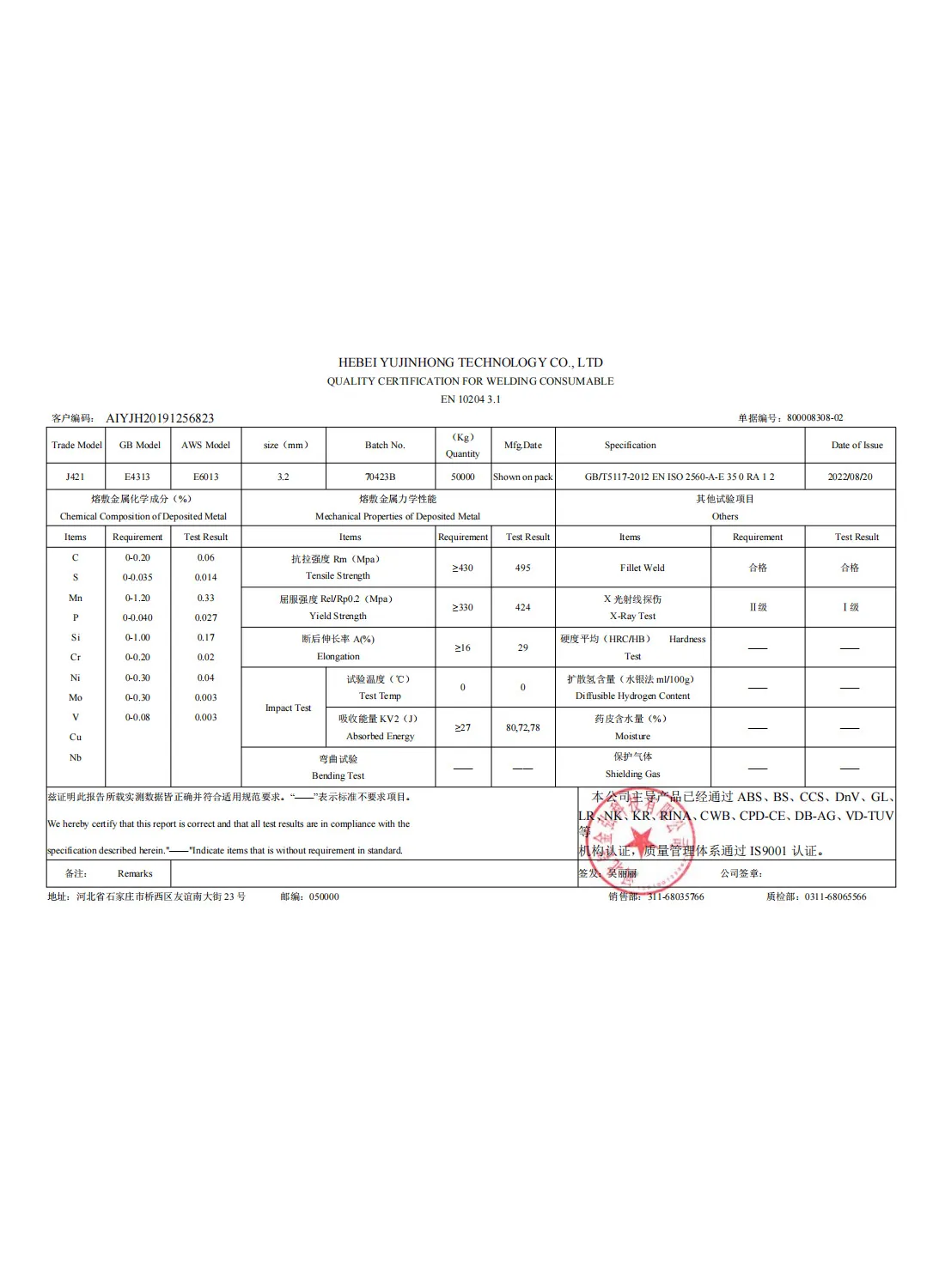

wholesale china welding wire factory

4. Scalability For businesses experiencing growth, the ability to scale up orders is crucial. Chinese wholesale factories typically have the capacity to handle large volume orders, ensuring that businesses can meet their increasing demand without delays.

Challenges and Considerations

While there are numerous advantages, sourcing welding wires from China also presents certain challenges.

1. Quality Control Although many factories adhere to international standards, the quality can vary significantly from one manufacturer to another. It is essential for businesses to conduct thorough research and due diligence, possibly even visiting factories when feasible, to ensure they are dealing with reputable suppliers.

2. Long Lead Times Importing products from overseas can involve longer lead times due to shipping logistics, customs clearance, and potential delays. Companies must plan their inventory needs accordingly to prevent project interruptions.

3. Regulatory Compliance Different countries have specific regulations regarding imported materials. Understanding and complying with these regulations is essential to avoid costly fines or delays.

Conclusion

Wholesale Chinese welding wire factories represent a vital resource for industries reliant on high-quality welding materials. The combination of cost-effectiveness, diverse product offerings, and technological advancements makes China an attractive sourcing destination. However, potential buyers must remain vigilant and perform due diligence to navigate the challenges associated with international sourcing. By strategically partnering with trustworthy manufacturers, businesses can ensure they secure the best materials to support their operations, ultimately driving success in their projects.

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025