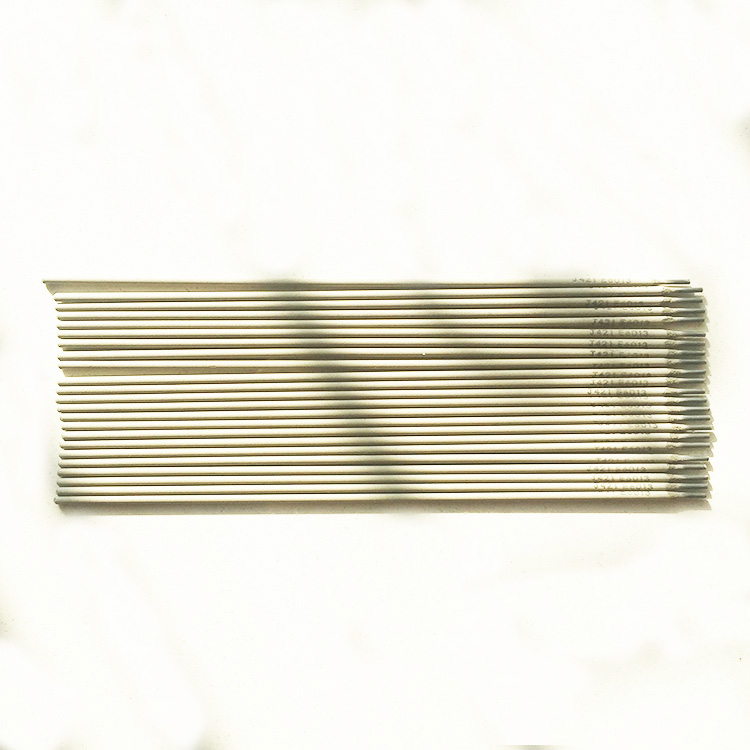

AWS E6010 Welding Rods – Deep Penetration, Fast-Freeze

AWS E6010 Electrodes: Field Notes, Real Specs, and Buying Tips

If you’ve spent time under a hood, you’ve probably run beads with Aws E6010 Welding Rods. They’re the get-it-done sticks for pipe roots—cellulosic, snappy arc, deep bite. In pipeline yards and repair rigs, they’re still the default. Industry trend? Despite the rise of semi-automatic downhill flux-cored on long runs, cellulosic E6010 remains king for open-root starts, tie-ins, and tricky fit-ups. Many foremen tell me: if the joint is dirty or out of round, you’ll want E6010 in your hand.

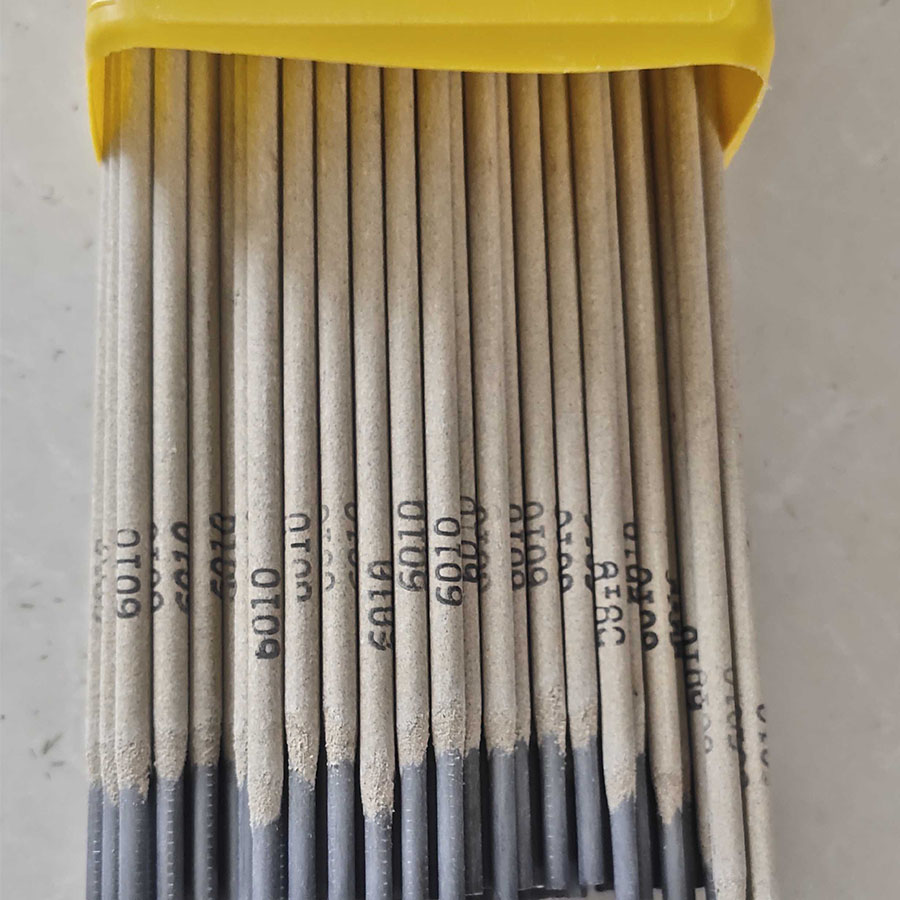

What makes E6010 tick?

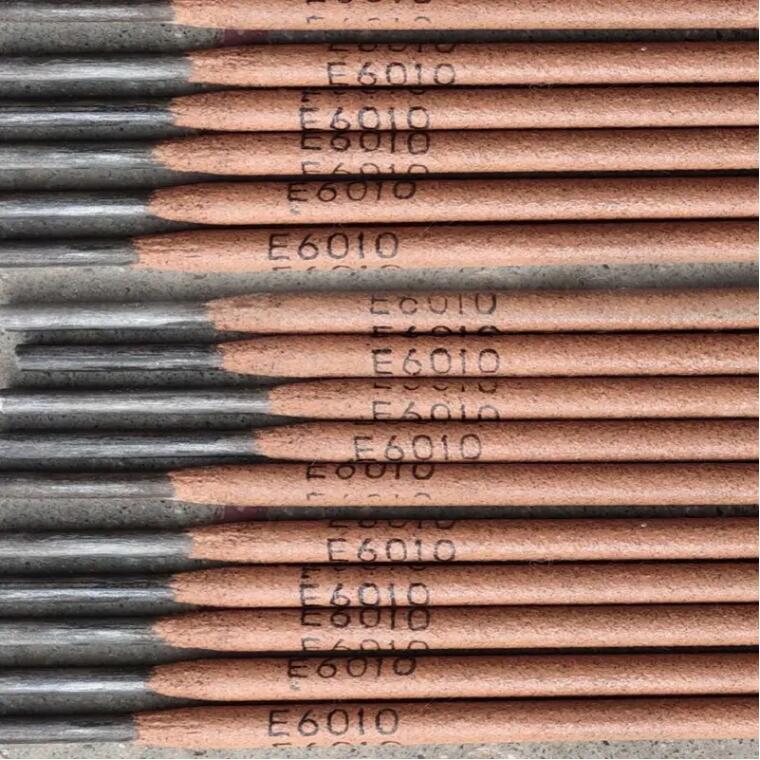

Technically speaking, this is a high cellulose sodium–type electrode optimized for DC+ (DCEP). The coating generates a forceful, digging arc and fast-freezing slag, which is why it excels at vertical-down on pipe. It’s remarkably forgiving on mill scale and light rust—though, to be honest, good prep still pays dividends.

| Spec | Details (≈ real-world) |

|---|---|

| Classification | AWS A5.1 E6010; typical ≥ 60 ksi (≈ 410 MPa) tensile |

| Coating / Polarity | High cellulose sodium; DCEP only |

| Positions | All, optimized for vertical-down (pipeline) |

| Typical mechanicals | Tensile 60–70 ksi; Yield ≈ 48–58 ksi; Elongation ≈ 22–28% |

| Diameters / Amps | 2.5 mm: 60–90 A; 3.2 mm: 80–110 A; 4.0 mm: 95–140 A (joint-dependent) |

| Storage | Room temp, dry; light re-dry ≈ 70–90°C for 30–60 min if needed (avoid high bake) |

Process flow and testing—quick overview

Materials: mild-steel core wire with a cellulosic (wood-pulp based) sodium-rich coating. Methods: precision extrusion, controlled drying (not “low-hydrogen” baking), batch sampling. Testing standards: AWS A5.1 mechanicals, arc performance evaluation; weld procedure qualification typically to ASME Section IX or API 1104 for pipelines. Service life: sealed cartons store well for 12–24 months; once opened, protect from humidity. Industries using Aws E6010 Welding Rods: pipeline transmission, field repair, storage tanks, structural tie-ins where fit-up is… let’s say “less than perfect.”

Why crews still pick them

- Deep penetration and arc force for dirty or tight roots.

- Fast-freezing slag supports vertical-down speed.

- Great for open-root passes; takes sidewall nicely.

- Feedback from crews: “Easy restarts, cuts through scale.”

Vendor snapshot (indicative, check current data)

| Vendor | Model | Certs | Customization | Lead time |

|---|---|---|---|---|

| SteelToolsChina (China, NO.368 YOUYI NORTH STREET…) | E6010 Pipe | AWS A5.1, ISO 9001 | Dia/branding/packaging | ≈ 10–25 days |

| Global Brand A | E6010 (pipeline) | AWS/ASME listings | Limited | Stock-dependent |

| Regional Supplier B | E6010 General | AWS claim | Basic | ≈ 2–4 weeks |

Customization and real-world notes

Aws E6010 Welding Rods can be tailored—diameters (2.5/3.2/4.0 mm), arc stiffness tweaks via coating formula, and private-label boxes for contractors. Actually, small changes in coating moisture can change arc “feel,” so specify if you prefer a softer start or a harder dig.

Mini case notes

Pipeline tie-in (temperate climate): 3.2 mm E6010 downhill roots, hot pass same rod, fill/cap with low-hy. RT acceptance rate 98.5% per API 1104—most indications tied to fit-up, not filler. Tank repair: 2.5 mm at 80–90 A, vertical-down seams; UT spot checks clean, visual profile uniform. It seems that experienced hands still outperform any spec sheet.

Usage tips

- DCEP, tight arc length, whip-and-pause for open-root.

- Preheat per code and thickness; for higher restraint steels, 50–100°C can help hydrogen management (consult WPS).

- Don’t overbake cellulosics; keep them dry, not toasted.

Standards and compliance

Aws E6010 Welding Rods are classified under AWS A5.1. Procedure qualification commonly follows ASME Section IX or API 1104. For international projects, ISO 2560 equivalents can be referenced. Certification and mill test data should be requested with each batch, especially for code work.

References

- AWS A5.1/A5.1M: Specification for Carbon Steel Electrodes for Shielded Metal Arc Welding – https://www.aws.org

- ASME Boiler & Pressure Vessel Code, Section IX (Welding Qualifications) – https://www.asme.org/codes-standards

- API 1104: Welding of Pipelines and Related Facilities – https://www.api.org

- ISO 2560-A: Welding consumables — Covered electrodes for manual metal arc welding of non-alloy and fine grain steels – https://www.iso.org

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025