Top Flux Core Welding Wire Manufacturers for Quality Performance and Reliability

The Best Flux Core Welding Wire Factory A Comprehensive Overview

Welding is an essential process in various industries, from construction to automotive, and the type of welding wire used can significantly affect the quality and strength of the welds. Among the different types of welding wires available, flux core welding wire has gained substantial popularity due to its versatility and ease of use. In this article, we will explore the best flux core welding wire factory, highlighting its offerings, production processes, and the advantages of using high-quality welding wire.

Understanding Flux Core Welding Wire

Flux core welding wire is designed for use in a MIG (Metal Inert Gas) welding process. Unlike solid welding wire, flux core wire has a core made of flux that provides shielding gas during the welding process. This feature allows for a more stable arc and less susceptibility to contamination from the environment, making it ideal for outdoor applications and projects that require welding in windy conditions. Additionally, the flux core wire can be used on thicker materials and offers good penetration, making it a preferred choice for various industrial applications.

The Importance of Quality in Welding Wire

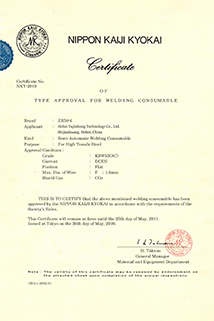

The quality of the welding wire significantly influences the final weld quality. Poor-quality wire can lead to issues such as slag inclusion, porosity, and insufficient strength, which can compromise the integrity of the welded structure. Therefore, it is essential to source welding wire from reputable manufacturers who adhere to strict quality control measures. The best flux core welding wire factory ensures that their products meet international standards and utilize advanced production techniques to guarantee consistency and reliability.

Features of a Leading Flux Core Welding Wire Factory

1. Advanced Manufacturing Techniques The best factories employ cutting-edge technology and machinery to produce flux core welding wire. Automated processes enhance precision and reduce the likelihood of human error, which is vital in maintaining consistent product quality.

2. Quality Raw Materials A reputable factory sources high-quality raw materials for production. The use of premium steel alloys and flux materials not only improves performance but also extends the lifespan of the welding wire.

3. Comprehensive Testing Top manufacturers conduct rigorous testing of their products. This includes tensile strength tests, impact tests, and metallurgical analysis to ensure that the welding wire can withstand the demands of various applications.

best flux core welding wire factory

4. Wide Range of Products The best factories offer a diverse range of flux core welding wires tailored for different applications. This includes wires designed for welding mild steel, stainless steel, and even specialized alloys, catering to a broad spectrum of industries.

5. Expertise and Innovation A commitment to research and development is vital for any leading factory. By staying updated with industry trends and technological advancements, these manufacturers can continually improve their products and adapt to changing market needs.

Advantages of Choosing the Best Flux Core Welding Wire

1. Superior Weld Quality High-quality flux core welding wire results in strong, clean welds with minimal defects. This ensures durability and safety in welded structures, making it a sound investment.

2. Increased Efficiency Using reliable welding wire can enhance productivity, allowing welders to work faster and with greater confidence. This is particularly important in industries where time is money.

3. Cost-Effective Solutions Although high-quality welding wire may come at a slightly higher initial cost, the long-term savings in material and labor costs due to fewer reworks and repairs can be significant.

4. Versatility The best flux core welding wire is versatile enough to be used in various applications, whether in fabrication shops, construction sites, or maintenance and repair situations.

Conclusion

When it comes to welding, the choice of flux core welding wire plays a pivotal role in determining the success of a project. The best flux core welding wire factory stands out by focusing on quality, innovation, and customer satisfaction. By investing in high-quality welding wire, welders can achieve superior results, ensuring that their work meets the highest standards of excellence. Whether for industrial applications or DIY projects, choosing the right welding wire is crucial for achieving strong, reliable welds that stand the test of time.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025