Cast Iron Welding Rod Electrode AWS ENi-Cl for Cold Welding?

Cast Iron Welding Rod Electrode AWS ENi-Cl is a key solution in the industrial manufacturing industry, specifically within Welding and cutting equipment and consumables and welding consumables. This article explores how HEBEI YUJINHONG TECHNOLOGY CO.,LTD. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Cast Iron Welding Rod Electrode AWS ENi-Cl Overview

- Benefits & Use Cases of Cast Iron Welding Rod Electrode AWS ENi-Cl in welding consumables

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in industrial manufacturing

- Conclusion on Cast Iron Welding Rod Electrode AWS ENi-Cl from HEBEI YUJINHONG TECHNOLOGY CO.,LTD.

Cast Iron Welding Rod Electrode AWS ENi-Cl Overview

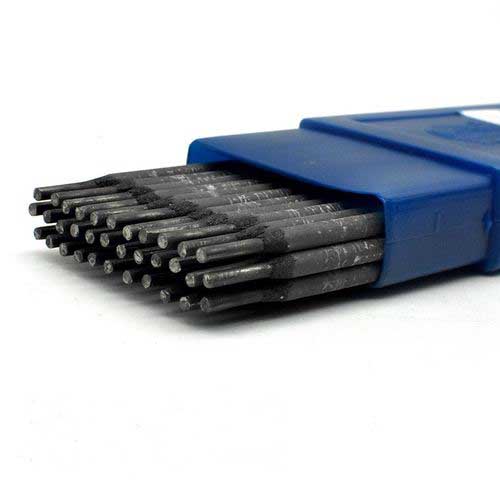

The Cast Iron Welding Rod Electrode AWS ENi-Cl is a nickel-based covered stick electrode engineered for joining and repairing cast irons—particularly gray cast iron—across workshop, maintenance, and field environments. In the context of industrial manufacturing and welding consumables, it is valued for its crack resistance, ductility, and clean, machinable weld deposits that minimize rework. Classified under the AWS ENi-Cl category, it is commonly selected for cold or low-heat-input techniques that help control heat-affected zone hardness and reduce the risk of cracking in cast components.

Typical usage parameters include operation on AC or DC+ power sources, with popular diameters such as 2.5 mm, 3.2 mm, and 4.0 mm to match joint size and positional needs. The electrode’s flux system promotes stable arcs, good wetting, and low spatter, making it suitable for all-position repair work when implemented with proper bead placement and peening practices. From engine blocks and gear housings to machinery bases and pump bodies, this electrode streamlines complex repairs that would otherwise demand costly replacement castings.

HEBEI YUJINHONG TECHNOLOGY CO.,LTD. manufactures and supplies the Cast Iron Welding Rod Electrode AWS ENi-Cl with a focus on consistency, traceability, and dependable batch-to-batch performance. Their production and quality assurance processes are designed to deliver electrodes that light easily, run smoothly, and produce predictable results for professional users—essential for B2B buyers managing uptime, quality KPIs, and cost control.

Benefits & Use Cases of Cast Iron Welding Rod Electrode AWS ENi-Cl in welding consumables

For welding consumables buyers and maintenance leaders, the Cast Iron Welding Rod Electrode AWS ENi-Cl stands out for its breadth of application and low risk profile on sensitive castings. It enables precision repair of cracks, fractures, and surface defects in gray cast iron and select cast iron alloys when correct procedures are followed. Common targets include engine and compressor blocks, manifold flanges, hydraulic pump housings, press frames, machine beds, gearboxes, and foundry casting repairs (e.g., porosity or misruns).

Competitive advantages include a ductile, machinable deposit that accepts drilling, tapping, and milling with reduced tool wear; excellent crack resistance under restrained conditions; and stable arc characteristics that promote controlled, short beads for cold welding techniques. Its flux composition supports sound fusion while helping mitigate porosity on aged or oil-contaminated castings with appropriate cleaning and pre-weld preparation.

HEBEI YUJINHONG TECHNOLOGY CO.,LTD. brings sector-specific expertise, advising customers on procedure steps such as joint preparation, staged bead sequencing, peening, and interpass temperature management. For B2B decision makers, this combination of product performance and application support reduces risk on critical repairs, shortens turnaround time, and helps standardize best practices across multi-site maintenance teams and OEM/foundry partners.

Cost, Maintenance & User Experience

Although nickel-based cast iron electrodes command a premium price versus mild steel consumables, their total cost of ownership is favorable in high-stakes repairs. The Cast Iron Welding Rod Electrode AWS ENi-Cl lowers rework, limits part distortion, and produces machinable deposits—reducing secondary operations and scrap. For B2B operators, this translates into faster return-to-service, fewer replacement castings, and measurable savings on both labor and material.

Best practices for maintenance include storing electrodes sealed and dry, keeping them away from humidity, and cleaning castings thoroughly (degreasing, grinding out cracks, and beveling as needed). Short, skip-weld beads with light peening and controlled interpass temperature help maintain ductility and minimize residual stresses. Users in the Welding and cutting equipment and consumables sector consistently report smooth strike and re-strike, predictable puddle control, and clean slag release—traits that support operator efficiency and consistent quality outcomes on difficult-to-weld cast irons.

From an ROI perspective, the ability to rehabilitate high-value cast components in-house or at a trusted service center can compress lead times from weeks to hours or days. Standardizing on Cast Iron Welding Rod Electrode AWS ENi-Cl across maintenance teams also simplifies training, inventory planning, and procedural qualification, improving throughput and quality yields across the repair portfolio.

Sustainability & Market Trends in industrial manufacturing

Industrial manufacturing is prioritizing repair, remanufacturing, and circular-economy strategies to extend asset lifecycles and reduce embodied carbon. The Cast Iron Welding Rod Electrode AWS ENi-Cl directly supports these goals by enabling reliable repair of cast components instead of scrapping and recasting. This approach saves energy, reduces waste, and improves supply chain resilience—particularly relevant during volatile raw material and logistics cycles.

Regulatory trends and customer expectations are moving toward lower environmental impact, traceability, and responsible sourcing across welding consumables. HEBEI YUJINHONG TECHNOLOGY CO.,LTD. aligns with these expectations by emphasizing process control, consistent quality, and thoughtful packaging practices while supporting customers with technical guidance that minimizes rework and waste. Reduced scrap and fewer repeat welds not only lower costs but also reduce the overall environmental footprint of repair operations.

Market-wise, the growth of maintenance, repair, and overhaul (MRO) services, alongside increased adoption of predictive maintenance and condition-based monitoring, is elevating demand for dependable cast iron welding solutions. As a forward-thinking partner, HEBEI YUJINHONG TECHNOLOGY CO.,LTD. helps B2B leaders standardize on proven electrodes, streamline qualification and documentation, and implement robust, sustainability-minded repair workflows that scale.

Conclusion on Cast Iron Welding Rod Electrode AWS ENi-Cl from HEBEI YUJINHONG TECHNOLOGY CO.,LTD.

The Cast Iron Welding Rod Electrode AWS ENi-Cl delivers the reliability, ductility, and machinability B2B manufacturers need to perform critical cast iron repairs efficiently. Within industrial manufacturing and welding consumables, it enables predictable, low-risk outcomes on challenging components—reducing rework, downtime, and scrap. Backed by HEBEI YUJINHONG TECHNOLOGY CO.,LTD.’s quality and application support, it is a smart, scalable choice for MRO teams, OEMs, and foundries.

Contact us: email: info@steeltoolschina.com

Visit our website: https://www.steeltoolschina.com

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025