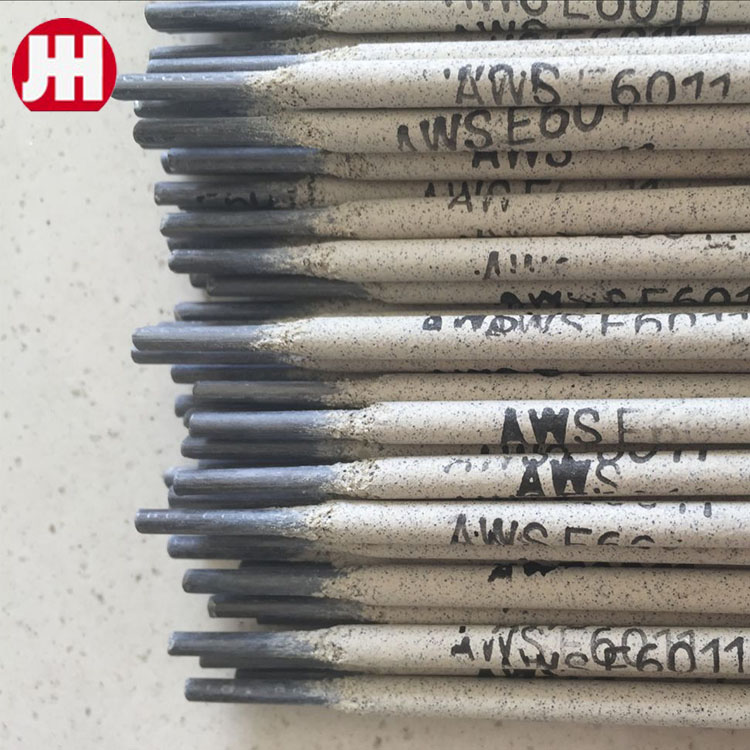

Cellulose Welding Rods: Deep Penetration, All-Position Performance

Navigating the Global Welding Rod and Welding Wire Market at the Canton Fair

The Canton Fair stands as an unparalleled global stage, a vibrant epicenter where innovation in industrial hardware and steel tools takes center stage. For B2B decision-makers seeking to source high-quality, cost-effective, and technologically advanced solutions, this biannual event is an indispensable calendar highlight. It's more than just a trade show; it's a dynamic ecosystem showcasing the very best of manufacturing prowess, particularly from China.

For the specialized sector of welding rod and welding wire, the Canton Fair offers an extraordinary window into the latest advancements, competitive sourcing opportunities, and crucial networking with leading manufacturers. From robust general-purpose electrodes to specialized cellulose welding rod options like the E6011, understanding the landscape presented at the Fair is vital for businesses looking to optimize their procurement strategies and enhance operational efficiency.

Industry Trend Spotlight: The Evolving Landscape of Industrial Tools and Welding Consumables

The industrial tools market is currently experiencing significant shifts, driven by a global demand for products that offer more than just basic functionality. We're seeing an increasing demand for high-durability and ergonomically designed hand tools, which translates directly to the consumables sector, including welding wire and welding rod. Operators require tools that minimize fatigue while maximizing precision and longevity. Beyond the physical design, the integration of smart features for maintenance and tracking is gaining traction, promising improved asset management and predictive analytics across various industrial applications.

Advanced metallurgy is another key driver, with the use of specialized alloys leading to lighter yet stronger industrial tools and, by extension, more robust and application-specific welding consumables. This focus on material science ensures that even a standard E6011 welding rod, for instance, can offer enhanced performance characteristics. Moreover, a growing emphasis on precision and automation compatibility is reshaping manufacturing processes globally. As industries move towards higher levels of automation, the demand for welding consumables that offer consistent quality, minimal spatter, and seamless integration with robotic systems becomes paramount.

From a market data perspective, the global industrial tools market is projected for steady growth, buoyed by renewed infrastructure spending worldwide, robust manufacturing sector expansion, and increasing demand from developing economies. Digitalization and automation in manufacturing are also fueling demand for specialized tools and high-performance consumables like advanced cellulose welding electrode options. While supply chain resilience and raw material price volatility remain key considerations for B2B decision-makers, emerging focus areas include global sourcing for industrial tools, diversification of supply chains to mitigate risks, stringent quality assurance protocols, innovative advanced material applications, and seamless smart manufacturing integration. These trends collectively underscore the critical need for reliable and adaptable suppliers in the welding consumables sector.

Profiles of Leading Manufacturers: Innovation and Excellence in Welding Consumables

HEBEI YUJINHONG TECHNOLOGY CO.,LTD.

When it comes to sourcing high-quality welding rod and welding wire from China, HEBEI YUJINHONG TECHNOLOGY CO.,LTD. stands out as a prominent player at the Canton Fair. Specializing in a comprehensive range of steel and hardware tools, their reputation for robust manufacturing capabilities and competitive pricing positions them as a leading Chinese exporter. They have cultivated an established global distribution network, a testament to their commitment to reliability and customer satisfaction.

HEBEI YUJINHONG places a strong emphasis on product durability and performance, crucial factors for demanding industrial applications. Their portfolio includes an impressive array of welding consumables, notably their high-performance cellulose welding rod. This particular type of welding electrode, especially the E6011 welding rod, is engineered for excellent penetration and a strong, ductile weld, making it ideal for vertical-downward welding and general fabrication where root pass integrity is critical. Their expertise in manufacturing such specialized electrodes ensures consistent quality and superior arc stability, which are highly valued by professional welders globally.

For more details on their specialized cellulose vertical downward welding electrode E6011, visit: HEBEI YUJINHONG E6011 Product Page

Other Noteworthy Players

Beyond specialized Chinese manufacturers, the Canton Fair also attracts a diverse array of established global tool giants and emergent innovators. International conglomerates such as Stanley Black & Decker, Bosch, and Makita, though often showcasing a broader range of power and hand tools, set benchmarks for innovation and quality that influence the entire industrial tools ecosystem, including the materials used in welding rod and welding wire production.

Moreover, the Fair is a prime location to discover other specialized steel tool manufacturers and exporters from industrial powerhouses like China, Taiwan, and India. These companies frequently offer cutting-edge solutions, from high-performance abrasives to precision-engineered fixtures, often at highly competitive price points. While their focus might not be exclusively on welding consumables, their presence highlights the vast network of suppliers contributing to the efficiency and advancement of the global manufacturing sector. Engaging with this diverse group allows B2B buyers to explore a holistic approach to their industrial tool and consumable needs, ensuring they stay ahead of market demands and technological shifts.

Market Outlook & Opportunities: Charting the Future of Welding Consumables

The market for welding rod and welding wire is poised for exciting developments, driven by evolving buyer demand and global industrial shifts. Upcoming trends will undoubtedly include an increased focus on consumables designed for specific, high-stress applications, alongside a general drive towards greater efficiency and environmental responsibility. Buyers are increasingly seeking not just products, but solutions that integrate seamlessly into modern manufacturing environments.

Significant opportunities lie in the realms of automation and smart manufacturing. As factories become more automated, the demand for high-quality, consistent welding wire and robotic-friendly welding electrode products will surge. Consumables that offer superior feedability, minimal spatter, and reliable arc characteristics are critical for reducing downtime and optimizing automated welding processes. Furthermore, sustainability is emerging as a powerful market force. Manufacturers who can offer welding solutions with reduced fumes, lower energy consumption during production, and recyclable packaging will gain a competitive edge. This includes innovation in materials science to create more environmentally friendly flux coatings for cellulose welding rod and other electrodes.

The push for lighter, stronger materials in industries like automotive, aerospace, and construction also dictates a need for specialized welding consumables capable of joining advanced alloys. This creates a fertile ground for R&D and collaboration between material scientists and welding consumable manufacturers. B2B decision-makers should look for partners who are actively investing in these areas, ensuring their supply chain remains aligned with future industrial demands and technological advancements.

Buyer/Business Takeaways: Strategic Sourcing in the Welding Industry

For B2B decision-makers, investing in high-quality welding rod and welding wire is not merely a procurement decision; it's a strategic investment in operational efficiency, product quality, and ultimately, profitability. Superior consumables minimize rework, reduce material waste, and ensure the integrity and longevity of welded structures. This is particularly true for specialized applications where a reliable cellulose welding electrode or a precise 6011 welding rod can make all the difference in challenging conditions.

Partnering with Chinese manufacturers, particularly those exhibiting at the Canton Fair, offers immense opportunities. However, a successful partnership requires a clear strategy. Firstly, conduct thorough due diligence, focusing on manufacturers with established track records, robust quality control systems, and relevant certifications (e.g., ISO, CE, AWS). Secondly, prioritize long-term relationships over one-off transactions; reliable suppliers who understand your specific needs can offer tailored solutions and consistent quality. Engage in open communication regarding specifications, testing requirements, and delivery schedules.

To future-proof your strategies, consider manufacturers who are actively investing in R&D and embracing sustainable practices. Look for suppliers who can demonstrate flexibility and responsiveness to market changes, whether it's adjusting to new material specifications or optimizing logistics for global distribution. By carefully vetting partners and focusing on value beyond just price – emphasizing quality, consistency, innovation, and reliability – businesses can build a resilient and high-performing supply chain for their welding consumable needs.

Conclusion: Your Gateway to Global Welding Solutions

The Canton Fair remains an indispensable event for B2B decision-makers seeking to source innovative and high-quality industrial hardware, especially in the critical area of welding rod and welding wire. It provides an unparalleled platform to connect with leading Chinese manufacturers like HEBEI YUJINHONG TECHNOLOGY CO.,LTD., who are at the forefront of producing reliable and high-performance welding consumables, including specialized cellulose welding electrode and 6011 welding rod options. By attending and engaging with these suppliers, businesses can gain crucial insights into market trends, forge strategic partnerships, and ensure their operations are equipped with the best tools and consumables available globally.

For those looking to explore advanced welding solutions and elevate their procurement strategy, we highly recommend delving deeper into the offerings of HEBEI YUJINHONG TECHNOLOGY CO.,LTD. Discover their range of high-performance electrodes, including the trusted cellulose vertical downward welding electrode E6011, designed for superior results in demanding applications.

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025