China ER70S-6 MIG Welding Wire for Superior Performance and Durability in Various Applications

Understanding China Welding Wire MIG ER70S-6 Key Features and Applications

Welding is a crucial process in various industries, ranging from construction to automotive manufacturing. The choice of welding consumables significantly influences the quality and efficiency of welding operations. One such essential product is the MIG welding wire ER70S-6, which has gained prominence in both domestic and international markets, particularly in China. This article explores the characteristics, applications, and advantages of China’s MIG ER70S-6 welding wire.

What is MIG ER70S-6?

MIG (Metal Inert Gas) welding, also known as Gas Metal Arc Welding (GMAW), utilizes a continuously fed wire electrode and an inert gas to shield the weld pool from atmospheric contamination. The designation ER70S-6 indicates specific characteristics of the welding wire. ER stands for Electrode Rod, 70 denotes the tensile strength of the weld (in thousands of psi), S signifies that it is a solid wire, and -6 denotes additional requirements regarding chemical composition and mechanical properties.

The ER70S-6 wire is specifically formulated for welding low carbon steels, and it is particularly effective for applications requiring good impact toughness and ductility. Its composition typically includes various alloying elements, which enhance its performance in different welding conditions.

Key Features

1. Excellent Weldability The ER70S-6 wire offers excellent arc stability and is easy to use, making it suitable for both novice and experienced welders. It has a broad operating window, which translates to better control over the welding process.

2. Strong Mechanical Properties This wire provides strong impact resistance, making it ideal for structural components subjected to dynamic loads. Its high tensile strength contributes to producing high-quality welds that can withstand harsh conditions.

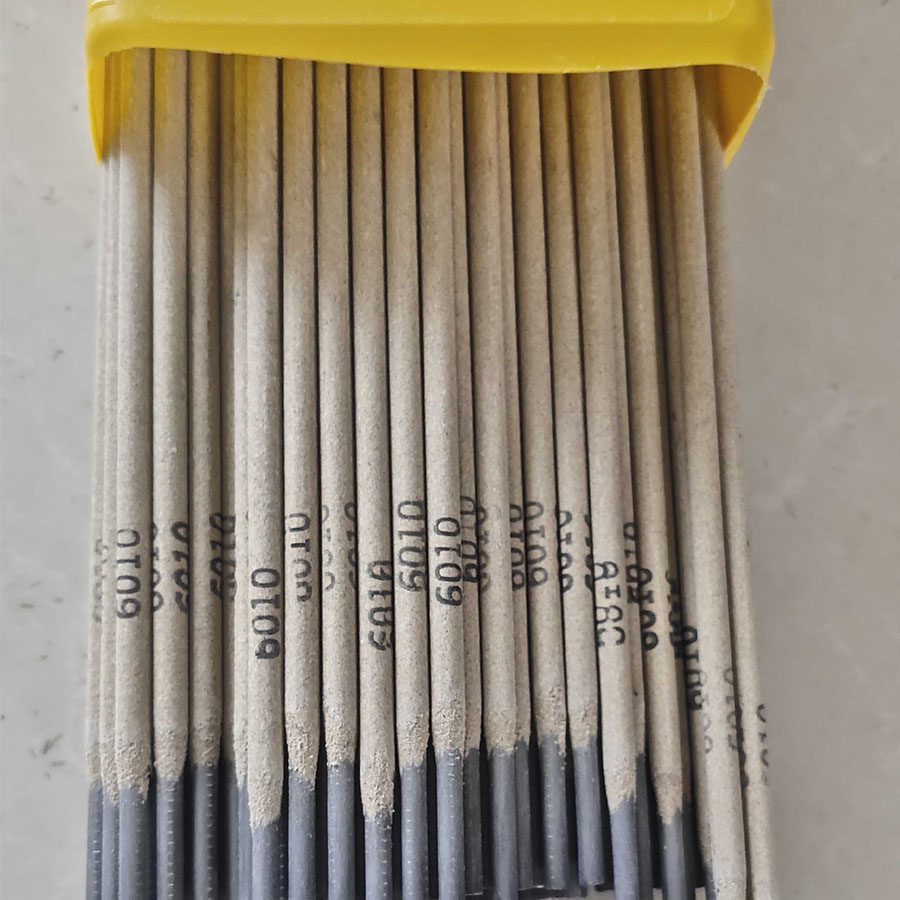

china welding wire mig er70s-6

3. Versatile Applications The ER70S-6 wire can be used in various welding techniques, including short circuit, spray, and pulse modes. This versatility makes it a popular choice for many applications, including automotive repair, general fabrication, and construction.

4. Good Deposit Characteristics The wire produces a smooth and spatter-free weld bead, which reduces the need for post-weld cleaning and rework. This characteristic is especially advantageous in high-volume production environments.

5. Availability and Cost-Effectiveness China is one of the leading manufacturers of welding consumables, including the MIG ER70S-6 wire. The extensive production capabilities in China enable competitive pricing, making it accessible for various sectors.

Applications

The ER70S-6 welding wire is widely used across several industries due to its adaptability and strength. Some common applications include

- Construction It is frequently used in the construction of buildings and other infrastructures, where strong, durable welds are imperative. - Automotive Industry The automotive sector utilizes this wire for manufacturing and repairing vehicles, ensuring that structural integrity is maintained. - Shipbuilding Due to its corrosion resistance and ability to withstand harsh marine environments, ER70S-6 is also a preferred choice in shipbuilding. - Heavy Machinery The wire is ideal for welding heavy machinery components that require high-strength joints.

Conclusion

In conclusion, China’s MIG welding wire ER70S-6 is a versatile and reliable choice for various welding applications. Its excellent weldability, strong mechanical properties, and cost-effectiveness make it an indispensable material in multiple industries. As manufacturing advancements continue to evolve, the demand for high-quality welding consumables like ER70S-6 will undoubtedly rise, underscoring the importance of this product in modern welding practices. Whether for small repair jobs or large-scale industrial projects, MIG ER70S-6 remains a staple for welders aiming for precision and durability.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025