High-Quality China Flux Core Welding Wire .035 - Durable and Reliable Welding Solutions

Understanding China Flux Core Welding Wire 0.35

Flux core welding has gained significant prominence in the welding industry due to its efficiency and versatility. Among the various products available, the China flux core welding wire 0.35 stands out as a popular choice for both professional welders and DIY enthusiasts. This article delves into the characteristics and advantages of this welding wire.

Flux core welding wire, particularly the 0.35 mm variant, is specifically designed to enhance the welding process by providing a continuous feed of filler material. One of the key features of this welding wire is its tubular structure, which contains a flux core that helps in shielding the weld pool from atmospheric contamination. This makes it an ideal choice for outdoor welding projects, where wind can disperse shielding gases that are used in traditional MIG welding.

The 0.35 mm diameter of the wire provides a balance between weld penetration and control, making it suitable for a wide range of applications. It is commonly used for welding thin to medium thickness materials, such as pipes, plates, and various structural components. Welders are often drawn to this size due to its ease of handling and the quality of the welds it produces.

china flux core welding wire 035

One of the significant advantages of using China flux core welding wire 0.35 is its cost-effectiveness. Manufacturing processes in China have led to high-quality products at competitive prices. This accessibility allows both small workshops and large industries to benefit from a reliable welding solution without breaking the bank. The wire can be utilized with both gas-shielded and self-shielded methods, further enhancing its versatility in various welding scenarios.

In addition to cost benefits, this type of welding wire ensures excellent weld quality. The flux core provides a good amount of metal transfer while minimizing spatter, which is often a concern with other types of welding wires. As a result, the finished welds are cleaner, requiring less post-weld cleaning and reducing the overall project time.

Moreover, welders find that using the China flux core welding wire 0.35 enhances their productivity. With minimal setup and quick learning curve, even novice welders can achieve professional results. This attribute makes the wire a go-to option for repairs, maintenance, and in fabrication settings.

In conclusion, the China flux core welding wire 0.35 is an invaluable resource for welders seeking efficiency, quality, and affordability. Its characteristics make it suitable for a variety of applications, proving that it is a wise choice for anyone involved in metalworking. As the welding industry continues to evolve, products like this are poised to play a crucial role in meeting the diverse needs of welders around the world.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

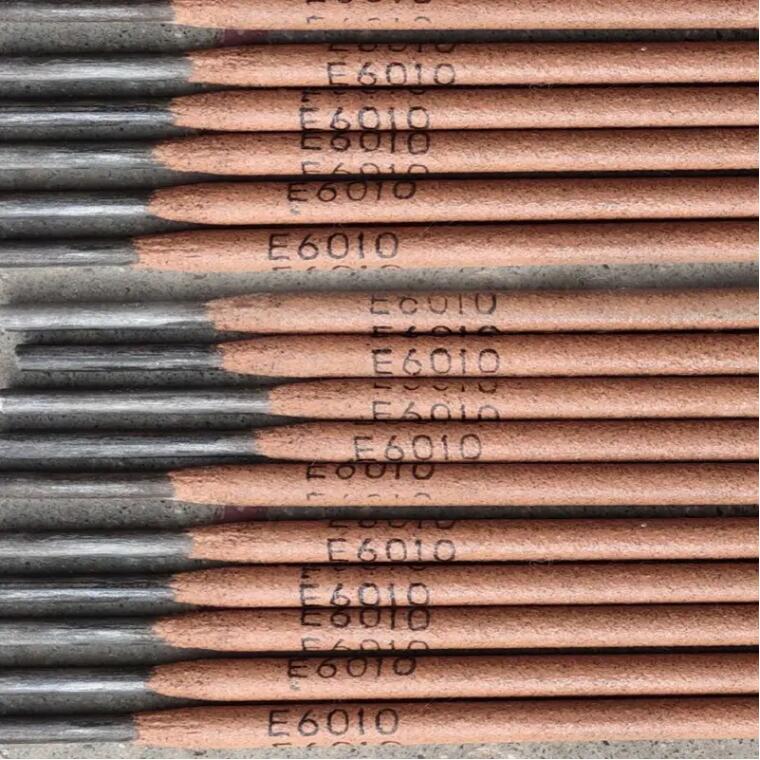

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025