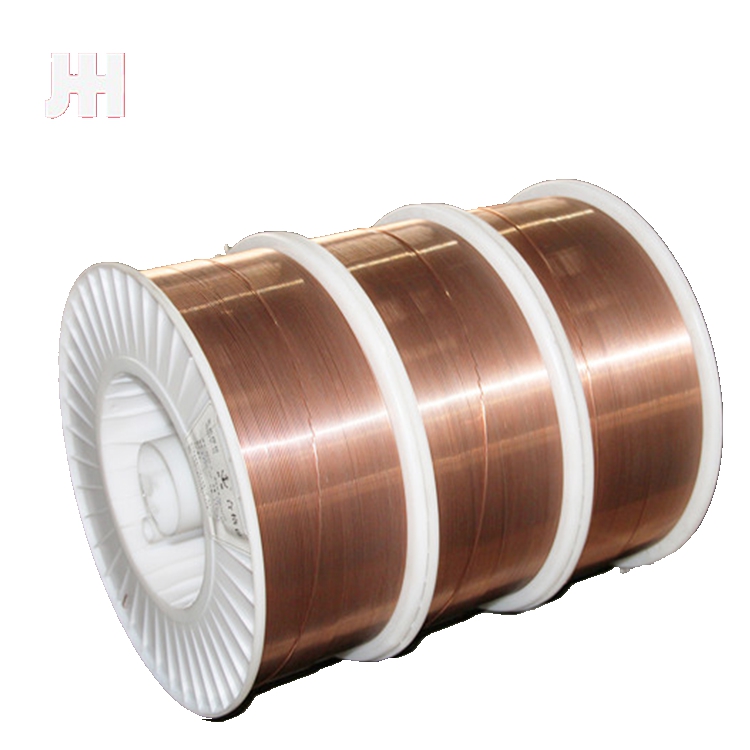

china 025 flux cored welding wire

The Rise of China 20025 Flux-Cored Welding Wire An Overview

In the evolving landscape of welding materials, China 20025 flux-cored welding wire has emerged as a significant player. Known for its reliability and versatility, this type of wire is widely used in various industrial applications, particularly for its efficiency and cost-effectiveness.

Understanding Flux-Cored Welding

Flux-cored arc welding (FCAW) is a slightly different process from traditional arc welding techniques. It utilizes a tubular wire filled with flux, which provides a shielding gas once heated. This gas helps protect the molten weld pool from contamination, ensuring a high-quality weld. The China 20025 flux-cored welding wire is particularly notable for its ability to produce strong, clean welds in a range of environments and conditions.

Key Characteristics of China 20025

1. Material Composition China 20025 flux-cored wire is primarily made from carbon steel, making it suitable for various applications. The wire features a composition that enhances its mechanical properties, offering good tensile strength and ductility.

2. Weld Quality One of the main advantages of using China 20025 is its ability to produce welds with excellent penetration and minimal spatter. This characteristic is vital for industries where weld integrity is crucial, such as construction and automotive manufacturing.

3. Multi-Positional Welding The wire is designed for multi-position welding, allowing for flexibility during the welding process. Whether the task requires overhead, vertical, or horizontal welding, China 20025 meets the challenge with ease.

4. Efficiency With a fast deposition rate, this flux-cored wire significantly reduces the time needed to complete projects, leading to increased productivity on job sites. This efficiency often translates into lower labor costs, making it an attractive option for businesses.

Applications

china 025 flux cored welding wire

The versatility of China 20025 flux-cored welding wire makes it suitable for various applications. It is commonly used in

- Construction Structures involving heavy steel components benefit from the robust welds produced by this wire. - Manufacturing Factories that produce machinery or equipment frequently employ this welding wire due to its reliability and strength. - Automotive Industry In automotive welding, the need for strong, durable joints is paramount, and China 20025 meets these requirements effectively.

Advantages Over Traditional Welding Methods

One of the significant benefits of using flux-cored wires like China 20025 over traditional welding methods is the reduced need for external shielding gases. While gas-shielded processes require a separate gas tank, flux-cored welding provides its shielding through the flux within the wire, simplifying logistics and reducing setup time.

Quality and Standards

China 20025 welding wire adheres to numerous international quality standards. This compliance ensures that users can trust the performance and reliability of the wire in various applications. Welding personnel often appreciate the consistency in product quality, which minimizes the chances of defects and rework.

Economic Impact

The increasing demand for China 20025 flux-cored welding wire is not only beneficial for manufacturers but also contributes positively to the economy. As more industries embrace this welding technology, job creation in production, distribution, and skilled labor sectors is on the rise. Moreover, the cost-effectiveness of this wire encourages businesses to invest in larger projects, thereby bolstering economic growth.

Conclusion

China 20025 flux-cored welding wire represents a significant advancement in welding technology, offering numerous benefits that cater to the needs of modern industrial applications. Its combination of quality, efficiency, and versatility makes it an essential tool for welders and manufacturers alike. As industries continue to grow and evolve, the reliance on efficient welding solutions like China 20025 will undoubtedly play a crucial role in enhancing production capabilities and ensuring the longevity of welded structures. With further developments and innovations on the horizon, this welding wire will likely solidify its position as a staple in the welding industry for years to come.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025