Suppliers of Welding Rods for China 1/8 7018 Specifications

The Importance of Winding Quality A Look at China’s 1/8” 7018 Welding Rod Suppliers

In the world of welding, the materials used play a critical role in determining the quality and strength of the weld. One of the most popular welding rods in use today is the 1/8” 7018 rod, renowned for its versatility and effectiveness in various welding applications. This article delves into the significance of selecting high-quality 7018 welding rods and explores the landscape of suppliers in China.

Understanding the 7018 Welding Rod

The 7018 welding rod belongs to the E7018 classification, indicating that it has a minimum tensile strength of 70,000 psi and is best suited for applications requiring low hydrogen levels. This rod is commonly used in structural welding, heavy machinery repairs, and fabrication projects that demand strong, ductile joints. Its low hydrogen content minimizes the risk of cracks in the weld, making it a preferred choice for critical welds in industries such as construction and manufacturing.

The Role of Suppliers in Quality Assurance

As the demand for 7018 welding rods increases, so does the pool of suppliers. In China, many manufacturers specialize in producing high-quality welding rods to cater to both domestic and international markets. These suppliers play a crucial role in ensuring that the rods meet stringent quality standards.

Quality assurance in welding rod production involves several steps, including the selection of raw materials, precise manufacturing processes, and rigorous testing. A reputable supplier emphasizes quality control at every stage, from sourcing iron and alloying elements to the packaging and distribution of the finished product. This commitment to quality not only enhances the performance of the welding rods but also ensures the safety and reliability of the welded structures.

The Advantages of Sourcing from China

China has become a global leader in manufacturing, and its welding rod suppliers offer numerous advantages. The primary benefits include

1. Cost-Effectiveness Chinese manufacturers often provide competitive pricing due to lower labor costs and efficient production processes. This makes sourcing 7018 welding rods from China an appealing option for companies looking to reduce material costs without sacrificing quality.

2. Diverse Product Range Many suppliers in China offer a variety of welding rods, including different diameters and chemical compositions. This diversity allows customers to find the exact specifications they need for their projects.

china 1/8 7018 welding rod suppliers

3. Innovation and Technology Chinese manufacturers are increasingly adopting advanced technologies and automated processes in their production lines, which leads to higher consistency and quality in the products.

4. Strong Export Capabilities With established logistics networks, many Chinese suppliers can deliver products quickly and efficiently to global markets, ensuring a steady supply for customers.

Selecting a Reliable Supplier

While there are many suppliers to choose from, it's essential to conduct thorough research to find a reliable partner. Here are some tips for selecting a reputable 7018 welding rod supplier in China

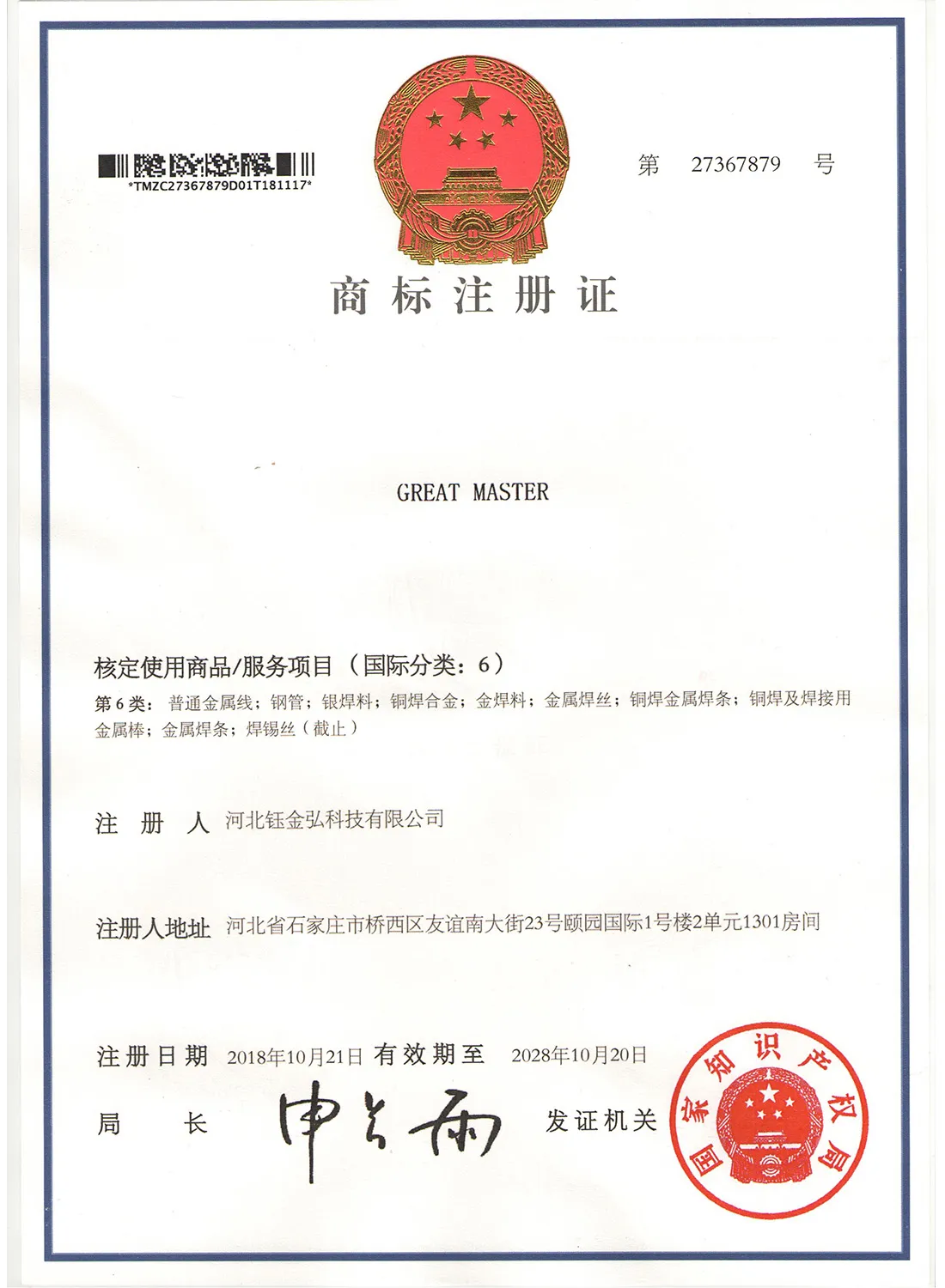

- Check Certifications Look for suppliers with relevant certifications such as ISO 9001, which indicates adherence to quality management standards.

- Request Product Samples Before making a bulk purchase, request samples to evaluate the quality of the welding rods firsthand.

- Read Reviews and Testimonials Customer feedback can provide insights into a supplier's reliability, product quality, and customer service.

- Evaluate Production Capacity Ensure the supplier can meet your demand requirements, especially if you need products in large quantities.

Conclusion

The 1/8” 7018 welding rod is indispensable in the welding industry, and selecting a high-quality supplier is crucial for successful projects. With a myriad of welding rod suppliers in China, businesses have access to cost-effective solutions without compromising on quality. By prioritizing reliable partnerships, companies can ensure that their welding operations run smoothly and efficiently, ultimately leading to safer and more durable products. As the industry evolves, sourcing from trusted suppliers will be key to maintaining high standards in welding practices.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025